Maximilian Kertel

Interactive and Intelligent Root Cause Analysis in Manufacturing with Causal Bayesian Networks and Knowledge Graphs

Jan 20, 2024

Abstract:Root Cause Analysis (RCA) in the manufacturing of electric vehicles is the process of identifying fault causes. Traditionally, the RCA is conducted manually, relying on process expert knowledge. Meanwhile, sensor networks collect significant amounts of data in the manufacturing process. Using this data for RCA makes it more efficient. However, purely data-driven methods like Causal Bayesian Networks have problems scaling to large-scale, real-world manufacturing processes due to the vast amount of potential cause-effect relationships (CERs). Furthermore, purely data-driven methods have the potential to leave out already known CERs or to learn spurious CERs. The paper contributes by proposing an interactive and intelligent RCA tool that combines expert knowledge of an electric vehicle manufacturing process and a data-driven machine learning method. It uses reasoning over a large-scale Knowledge Graph of the manufacturing process while learning a Causal Bayesian Network. In addition, an Interactive User Interface enables a process expert to give feedback to the root cause graph by adding and removing information to the Knowledge Graph. The interactive and intelligent RCA tool reduces the learning time of the Causal Bayesian Network while decreasing the number of spurious CERs. Thus, the interactive and intelligent RCA tool closes the feedback loop between expert and machine learning method.

Boosting Causal Additive Models

Jan 12, 2024

Abstract:We present a boosting-based method to learn additive Structural Equation Models (SEMs) from observational data, with a focus on the theoretical aspects of determining the causal order among variables. We introduce a family of score functions based on arbitrary regression techniques, for which we establish necessary conditions to consistently favor the true causal ordering. Our analysis reveals that boosting with early stopping meets these criteria and thus offers a consistent score function for causal orderings. To address the challenges posed by high-dimensional data sets, we adapt our approach through a component-wise gradient descent in the space of additive SEMs. Our simulation study underlines our theoretical results for lower dimensions and demonstrates that our high-dimensional adaptation is competitive with state-of-the-art methods. In addition, it exhibits robustness with respect to the choice of the hyperparameters making the procedure easy to tune.

Learning Causal Graphs in Manufacturing Domains using Structural Equation Models

Oct 26, 2022Abstract:Many production processes are characterized by numerous and complex cause-and-effect relationships. Since they are only partially known they pose a challenge to effective process control. In this work we present how Structural Equation Models can be used for deriving cause-and-effect relationships from the combination of prior knowledge and process data in the manufacturing domain. Compared to existing applications, we do not assume linear relationships leading to more informative results.

Estimating Gaussian Copulas with Missing Data

Jan 14, 2022

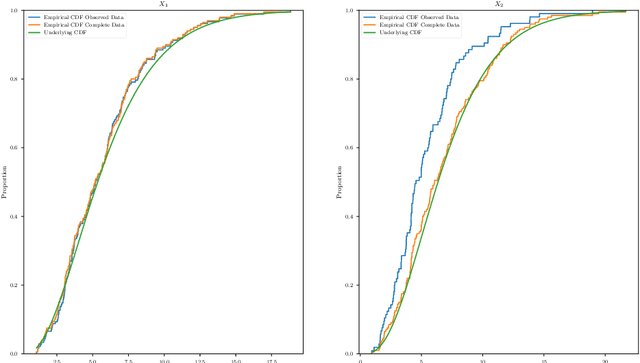

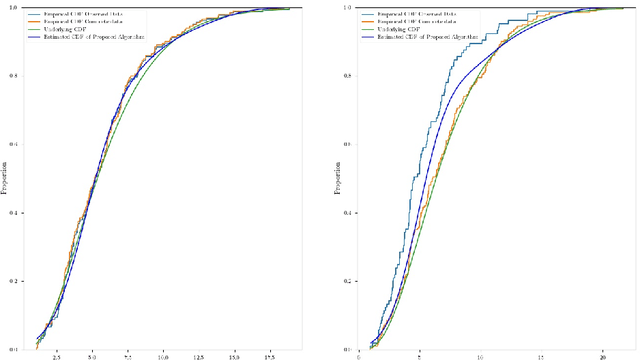

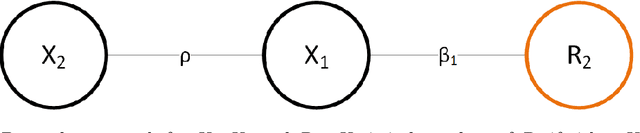

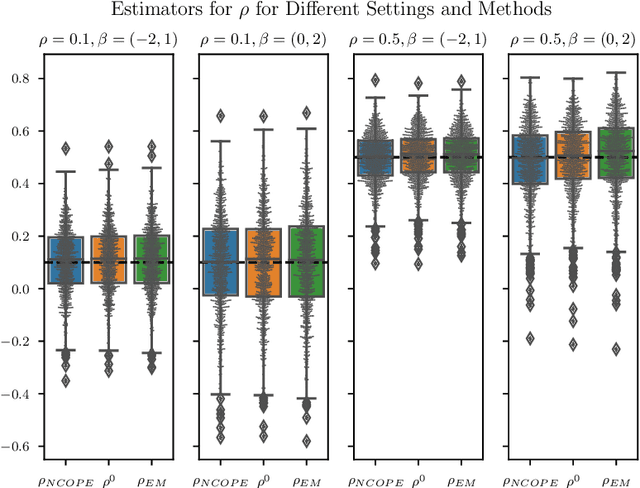

Abstract:In this work we present a rigorous application of the Expectation Maximization algorithm to determine the marginal distributions and the dependence structure in a Gaussian copula model with missing data. We further show how to circumvent a priori assumptions on the marginals with semiparametric modelling. The joint distribution learned through this algorithm is considerably closer to the underlying distribution than existing methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge