Marcus Geimer

KIT Bus: A Shuttle Model for CARLA Simulator

Jun 17, 2021

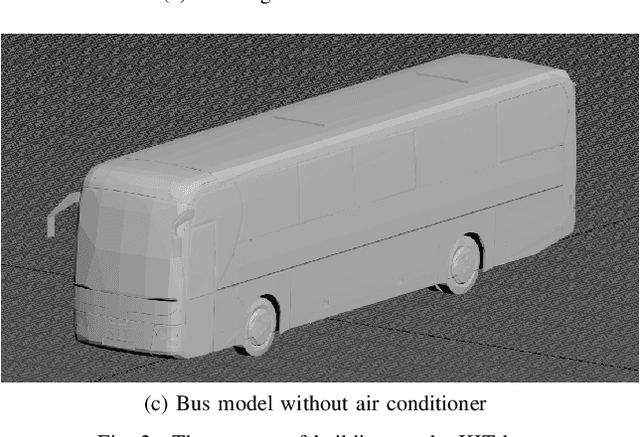

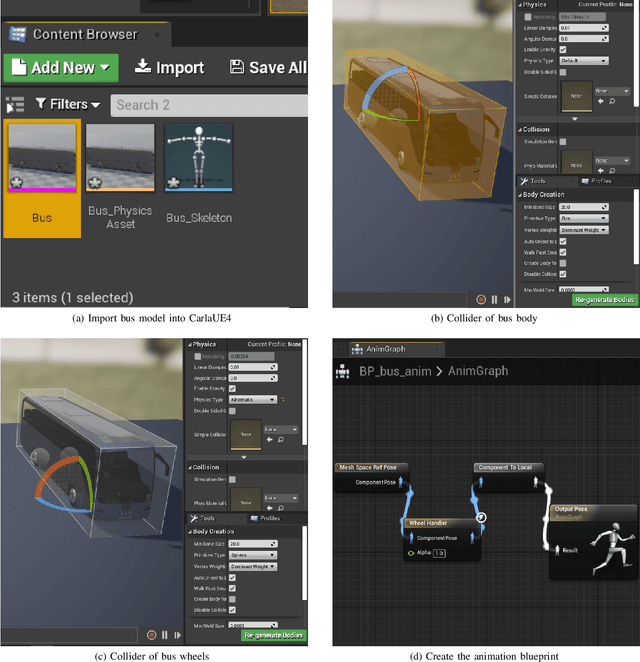

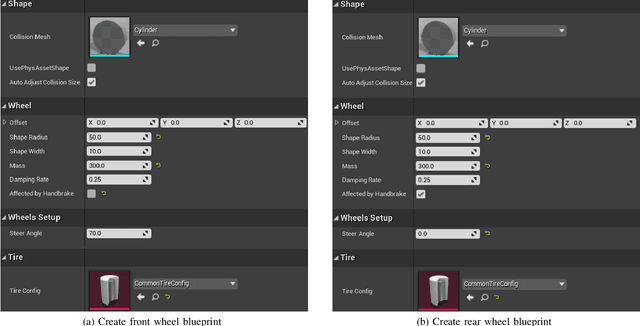

Abstract:With the continuous development of science and technology, self-driving vehicles will surely change the nature of transportation and realize the automotive industry's transformation in the future. Compared with self-driving cars, self-driving buses are more efficient in carrying passengers and more environmentally friendly in terms of energy consumption. Therefore, it is speculated that in the future, self-driving buses will become more and more important. As a simulator for autonomous driving research, the CARLA simulator can help people accumulate experience in autonomous driving technology faster and safer. However, a shortcoming is that there is no modern bus model in the CARLA simulator. Consequently, people cannot simulate autonomous driving on buses or the scenarios interacting with buses. Therefore, we built a bus model in 3ds Max software and imported it into the CARLA to fill this gap. Our model, namely KIT bus, is proven to work in the CARLA by testing it with the autopilot simulation. The video demo is shown on our Youtube.

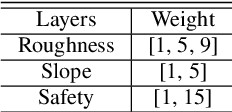

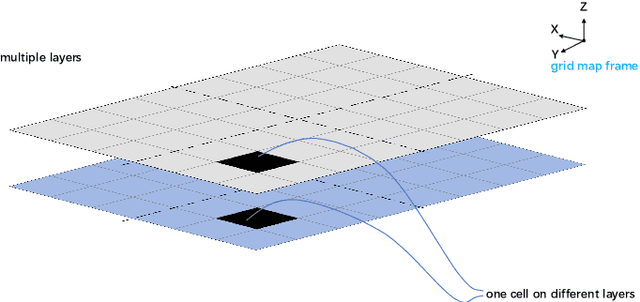

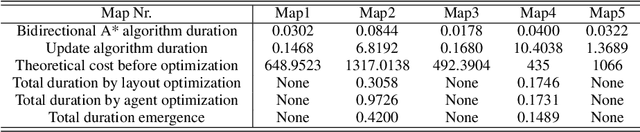

An Extension of BIM Using AI: a Multi Working-Machines Pathfinding Solution

May 14, 2021

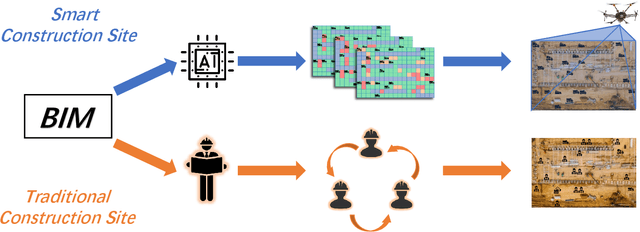

Abstract:Multi working-machines pathfinding solution enables more mobile machines simultaneously to work inside of a working site so that the productivity can be expected to increase evolutionary. To date, the potential cooperation conflicts among construction machinery limit the amount of construction machinery investment in a concrete working site. To solve the cooperation problem, civil engineers optimize the working site from a logistic perspective while computer scientists improve pathfinding algorithms' performance on the given benchmark maps. In the practical implementation of a construction site, it is sensible to solve the problem with a hybrid solution; therefore, in our study, we proposed an algorithm based on a cutting-edge multi-pathfinding algorithm to enable the massive number of machines cooperation and offer the advice to modify the unreasonable part of the working site in the meantime. Using the logistic information from BIM, such as unloading and loading point, we added a pathfinding solution for multi machines to improve the whole construction fleet's productivity. In the previous study, the experiments were limited to no more than ten participants, and the computational time to gather the solution was not given; thus, we publish our pseudo-code, our tested map, and benchmark our results. Our algorithm's most extensive feature is that it can quickly replan the path to overcome the emergency on a construction site.

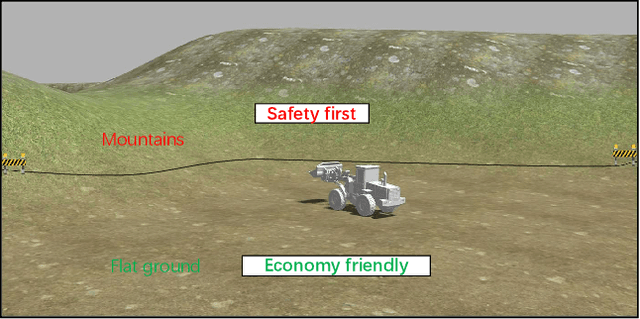

Where am I? SLAM for Mobile Machines on A Smart Working Site

Nov 05, 2020

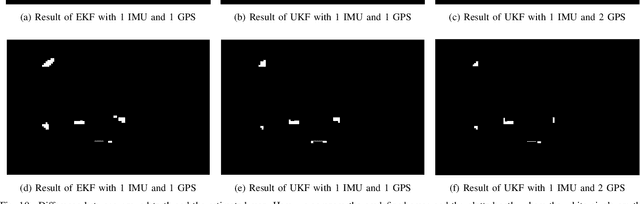

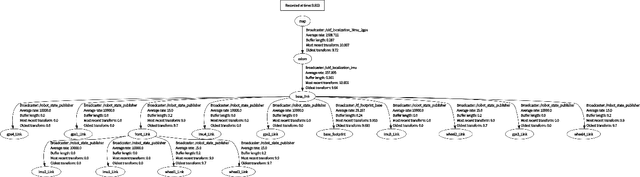

Abstract:The current optimization approaches of construction machinery are mainly based on internal sensors. However, the decision of a reasonable strategy is not only determined by its intrinsic signals, but also very strongly by environmental information, especially the terrain. Due to the dynamically changing of the construction site and the consequent absence of a high definition map, the Simultaneous Localization and Mapping (SLAM) offering the terrain information for construction machines is still challenging. Current SLAM technologies proposed for mobile machines are strongly dependent on costly or computationally expensive sensors, such as RTK GPS and cameras, so that commercial use is rare. In this study, we proposed an affordable SLAM method to create a multi-layer gird map for the construction site so that the machine can have the environmental information and be optimized accordingly. Concretely, after the machine passes by, we can get the local information and record it. Combining with positioning technology, we then create a map of the interesting places of the construction site. As a result of our research gathered from Gazebo, we showed that a suitable layout is the combination of 1 IMU and 2 differential GPS antennas using the unscented Kalman filter, which keeps the average distance error lower than 2m and the mapping error lower than 1.3% in the harsh environment. As an outlook, our SLAM technology provides the cornerstone to activate many efficiency improvement approaches.

KIT MOMA: A Mobile Machines Dataset

Jul 08, 2020

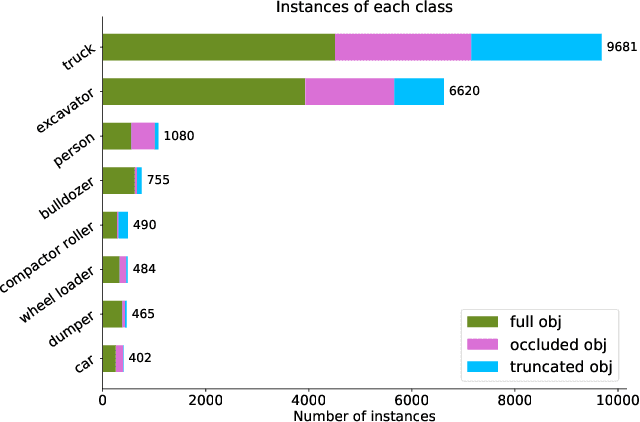

Abstract:Mobile machines typically working in a closed site, have a high potential to utilize autonomous driving technology. However, vigorously thriving development and innovation are happening mostly in the area of passenger cars. In contrast, although there are also many research pieces about autonomous driving or working in mobile machines, a consensus about the SOTA solution is still not achieved. We believe that the most urgent problem that should be solved is the absence of a public and challenging visual dataset, which makes the results from different researches comparable. To address the problem, we publish the KIT MOMA dataset, including eight classes of commonly used mobile machines, which can be used as a benchmark to evaluate the SOTA algorithms to detect mobile construction machines. The view of the gathered images is outside of the mobile machines since we believe fixed cameras on the ground are more suitable if all the interesting machines are working in a closed site. Most of the images in KIT MOMA are in a real scene, whereas some of the images are from the official website of top construction machine companies. Also, we have evaluated the performance of YOLO v3 on our dataset, indicating that the SOTA computer vision algorithms already show an excellent performance for detecting the mobile machines in a specific working site. Together with the dataset, we also upload the trained weights, which can be directly used by engineers from the construction machine industry. The dataset, trained weights, and updates can be found on our Github. Moreover, the demo can be found on our Youtube.

Fast CRDNN: Towards on Site Training of Mobile Construction Machines

Jun 04, 2020

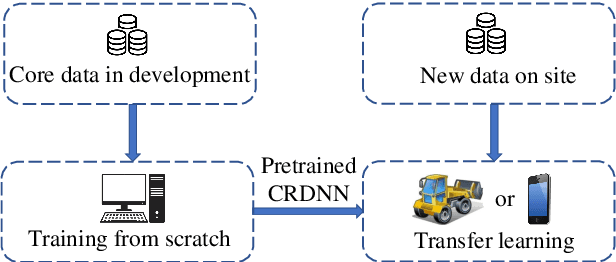

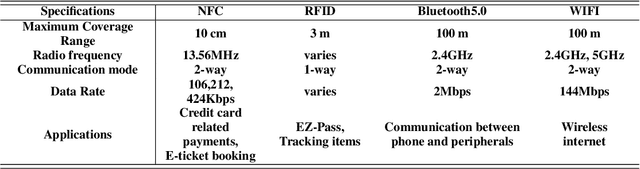

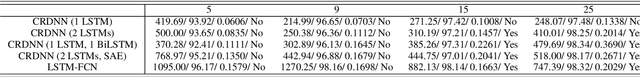

Abstract:The CRDNN is a combined neural network that can increase the holistic efficiency of torque based mobile working machines by about 9% by means of accurately detecting the truck loading cycles. On the one hand, it is a robust but offline learning algorithm so that it is more accurate and much quicker than the previous methods. However, on the other hand, its accuracy can not always be guaranteed because of the diversity of the mobile machines industry and the nature of the offline method. To address the problem, we utilize the transfer learning algorithm and the Internet of Things (IoT) technology. Concretely, the CRDNN is first trained by computer and then saved in the on-board ECU. In case that the pre-trained CRDNN is not suitable for the new machine, the operator can label some new data by our App connected to the on-board ECU of that machine through Bluetooth. With the newly labeled data, we can directly further train the pretrained CRDNN on the ECU without overloading since transfer learning requires less computation effort than training the networks from scratch. In our paper, we prove this idea and show that CRDNN is always competent, with the help of transfer learning and IoT technology by field experiment, even the new machine may have a different distribution. Also, we compared the performance of other SOTA multivariate time series algorithms on predicting the working state of the mobile machines, which denotes that the CRDNNs are still the most suitable solution. As a by-product, we build up a human-machine communication system to label the dataset, which can be operated by engineers without knowledge about Artificial Intelligence (AI).

Optimization of Operation Strategy for Primary Torque based hydrostatic Drivetrain using Artificial Intelligence

Mar 31, 2020

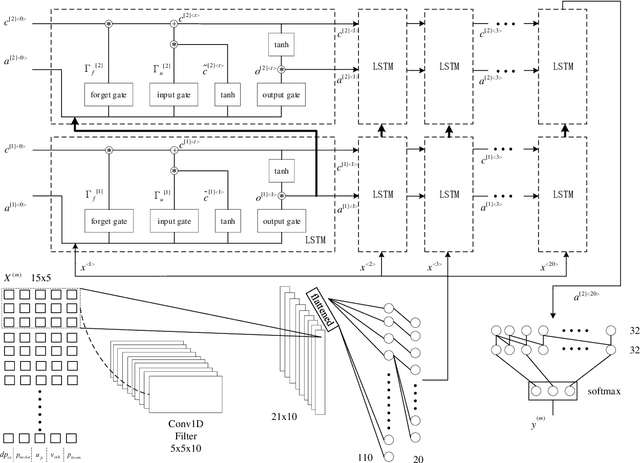

Abstract:A new primary torque control concept for hydrostatics mobile machines was introduced in 2018. The mentioned concept controls the pressure in a closed circuit by changing the angle of the hydraulic pump to achieve the desired pressure based on a feedback system. Thanks to this concept, a series of advantages are expected. However, while working in a Y cycle, the primary torque-controlled wheel loader has worse performance in efficiency compared to secondary controlled earthmover due to lack of recuperation ability. Alternatively, we use deep learning algorithms to improve machines' regeneration performance. In this paper, we firstly make a potential analysis to show the benefit by utilizing the regeneration process, followed by proposing a series of CRDNNs, which combine CNN, RNN, and DNN, to precisely detect Y cycles. Compared to existing algorithms, the CRDNN with bi-directional LSTMs has the best accuracy, and the CRDNN with LSTMs has a comparable performance but much fewer training parameters. Based on our dataset including 119 truck loading cycles, our best neural network shows a 98.2% test accuracy. Therefore, even with a simple regeneration process, our algorithm can improve the holistic efficiency of mobile machines up to 9% during Y cycle processes if primary torque concept is used.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge