Majid Nabavi

Semi-Supervised Health Index Monitoring with Feature Generation and Fusion

Dec 05, 2023

Abstract:The Health Index (HI) is crucial for evaluating system health, aiding tasks like anomaly detection and predicting remaining useful life for systems demanding high safety and reliability. Tight monitoring is crucial for achieving high precision at a lower cost, with applications such as spray coating. Obtaining HI labels in real-world applications is often cost-prohibitive, requiring continuous, precise health measurements. Therefore, it is more convenient to leverage run-to failure datasets that may provide potential indications of machine wear condition, making it necessary to apply semi-supervised tools for HI construction. In this study, we adapt the Deep Semi-supervised Anomaly Detection (DeepSAD) method for HI construction. We use the DeepSAD embedding as a condition indicators to address interpretability challenges and sensitivity to system-specific factors. Then, we introduce a diversity loss to enrich condition indicators. We employ an alternating projection algorithm with isotonic constraints to transform the DeepSAD embedding into a normalized HI with an increasing trend. Validation on the PHME 2010 milling dataset, a recognized benchmark with ground truth HIs demonstrates meaningful HIs estimations. Our methodology is then applied to monitor wear states of thermal spray coatings using high-frequency voltage. Our contributions create opportunities for more accessible and reliable HI estimation, particularly in cases where obtaining ground truth HI labels is unfeasible.

Advanced Manufacturing Configuration by Sample-efficient Batch Bayesian Optimization

May 24, 2022

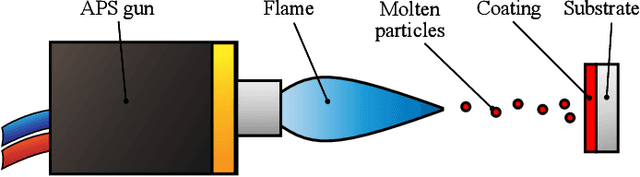

Abstract:We propose a framework for the configuration and operation of expensive-to-evaluate advanced manufacturing methods, based on Bayesian optimization. The framework unifies a tailored acquisition function, a parallel acquisition procedure, and the integration of process information providing context to the optimization procedure. The novel acquisition function is demonstrated and analyzed on benchmark illustrative problems. We apply the optimization approach to atmospheric plasma spraying in simulation and experiments. Our results demonstrate that the proposed framework can efficiently find input parameters that produce the desired outcome and minimize the process cost.

Sample-efficient Plasma Spray Process Configuration with Constrained Bayesian Optimization

Mar 25, 2021

Abstract:Recent work has shown constrained Bayesian optimization to be a powerful technique for the optimization of industrial processes. We adapt this framework to the set-up and optimization of atmospheric plasma spraying processes. We propose and validate a Gaussian process modeling structure to predict coatings properties. We introduce a parallel acquisition procedure tailored on the process characteristics and propose an algorithm that adapts to real-time process measurements to improve reproducibility. We validate our optimization method numerically and experimentally, and demonstrate that it can efficiently find input parameters that produce the desired coating and minimize the process cost.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge