Lutz Fassl

Advanced Manufacturing Configuration by Sample-efficient Batch Bayesian Optimization

May 24, 2022

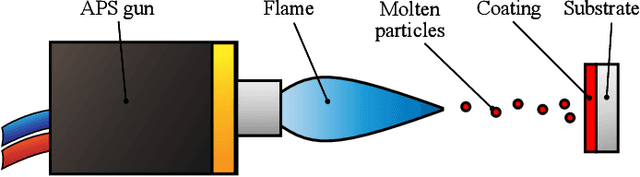

Abstract:We propose a framework for the configuration and operation of expensive-to-evaluate advanced manufacturing methods, based on Bayesian optimization. The framework unifies a tailored acquisition function, a parallel acquisition procedure, and the integration of process information providing context to the optimization procedure. The novel acquisition function is demonstrated and analyzed on benchmark illustrative problems. We apply the optimization approach to atmospheric plasma spraying in simulation and experiments. Our results demonstrate that the proposed framework can efficiently find input parameters that produce the desired outcome and minimize the process cost.

Sample-efficient Plasma Spray Process Configuration with Constrained Bayesian Optimization

Mar 25, 2021

Abstract:Recent work has shown constrained Bayesian optimization to be a powerful technique for the optimization of industrial processes. We adapt this framework to the set-up and optimization of atmospheric plasma spraying processes. We propose and validate a Gaussian process modeling structure to predict coatings properties. We introduce a parallel acquisition procedure tailored on the process characteristics and propose an algorithm that adapts to real-time process measurements to improve reproducibility. We validate our optimization method numerically and experimentally, and demonstrate that it can efficiently find input parameters that produce the desired coating and minimize the process cost.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge