M. Katherine Banks

A Self-rescue Mechanism for an In-pipe Robot for Large Obstacle Negotiation in Water Distribution Systems

Sep 15, 2021

Abstract:Water distribution systems (WDS) carry potable water with millions of miles of pipelines and deliver purified water to residential areas. The incidents in the WDS cause leak and water loss, which imposes pressure gradient and public health crisis. Hence, utility managers need to assess the condition of pipelines periodically and localize the leak location (in case it is reported). In our previous works, we designed and developed a size-adaptable modular in-pipe robot [1] and controlled its motion in in-service WDS. However, due to the linearization of the dynamical equations of the robot, the stabilizer controller which is a linear quadratic regulator (LQR) cannot stabilize the large deviations of the stabilizing states due to the presence of obstacles that fails the robot during operation. To this aim, we design a self-rescue mechanism for the robot in which three auxiliary gear-motors retract and extend the arm modules with the designed controller towards a reliable motion in the negotiation of large obstacles and non-straight configurations. Simulation results show that the proposed mechanism along with the motion controller enables the robot to have an improved motion in pipelines.

A Localization and Navigation Method for an In-pipe Robot in Water Distribution System through Wireless Control towards Long-Distance Inspection

May 21, 2021

Abstract:In this paper, we propose an operation procedure for our previously developed in-pipe robotic system that is used for water quality monitoring in water distribution systems (WDS). The proposed operation procedure synchronizes a developed wireless communication system that is suitable for harsh environments of soil, water, and rock with a multi-phase control algorithm. The new wireless control algorithm facilitates smart navigation and near real-time wireless data transmission during operation for our in-pipe robot in WDS. The smart navigation enables the robot to pass through different configurations of the pipeline with long inspection capability with a battery in which is mounted on the robot. To this end, we have divided the operation procedure into five steps that assign a specific motion control phase and wireless communication task to the robot. We describe each step and the algorithm associated with that step in this paper. The proposed robotic system defines the configuration type in each pipeline with the pre-programmed pipeline map that is given to the robot before the operation and the wireless communication system. The wireless communication system includes some relay nodes that perform bi-directional communication in the operation procedure. The developed wireless robotic system along with operation procedure facilitates localization and navigation for the robot toward long-distance inspection in WDS.

SmartCrawler: An In-pipe Robotic System with Wireless Communication in Water Distribution Systems

May 18, 2021

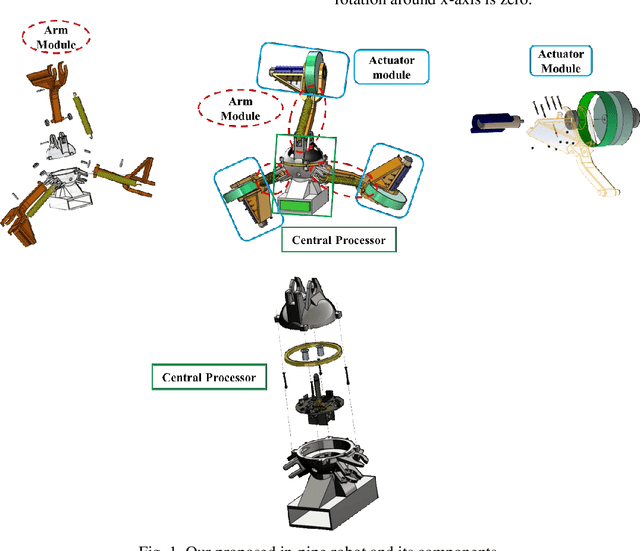

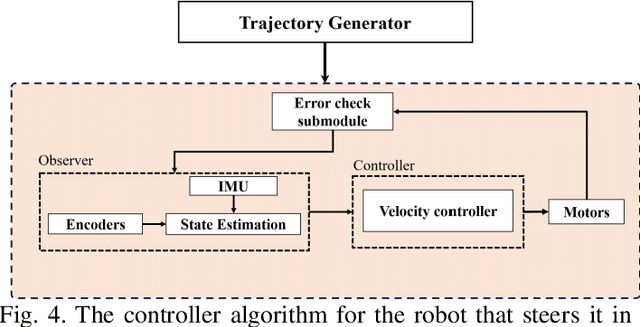

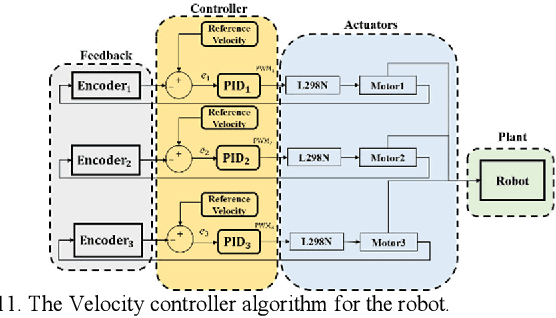

Abstract:Water Distribution Systems(WDS) are critical infrastructures that deliver potable water to residential areas. Incidents to pipelines cause water loss and contamination in pipelines. Hence, water quality monitoring is one of the requirements for utility managers to ensure the health of water. However, it is challenging to access all parts of the WDS since they are long and comprise pipes with different configurations and sizes. In this paper, we propose a size-adaptable and modular in-pipe robot so-called SmartCrawler that works based on wheel wall press mechanism. We develop a two-phase motion control algorithm that enables reliable motion in straight and non-straight configurations of in-service pipelines. The controller in phase 1 stabilizes the robot in the straight paths and tracks the desired velocity with high-level linear quadratic regulator (LQR) and low-level proportional-integral-derivative (PID) based controllers. The controller in phase 2 with a designed error-check submodule and velocity controller, enables the robot to steer to the desired directions at non-straight configurations. The performance of the two-phase controller is evaluated with experimental and simulation results. Wireless underground communication is a challenging task for underground applications. We propose a bi-directional wireless sensor module based on active radio frequency identification (RFID) that works in 434MHz carrier frequency and evaluate its performance with experimental results. At the end of this work, we design the printed circuit board (PCB) for the SmartCrawler that embeds the electronic components in a confined and sealed environment. The simulation and the experimental results prove the proposed robotic system can be used for in pipe missions where wireless communication is needed to communicate with the robot during operation.

Smart Navigation for an In-pipe Robot Through Multi-phase Motion Control and Particle Filtering Method

Feb 23, 2021

Abstract:In-pipe robots are promising solutions for condition assessment, leak detection, water quality monitoring in a variety of other tasks in pipeline networks. Smart navigation is an extremely challenging task for these robots as a result of highly uncertain and disturbing environment for operation. Wireless communication to control these robots during operation is not feasible if the pipe material is metal since the radio signals are destroyed in the pipe environment, and hence, this challenge is still unsolved. In this paper, we introduce a method for smart navigation for our previously designed in-pipe robot [1] based on particle filtering and a two-phase motion controller. The robot is given the map of the operation path with a novel approach and the particle filtering determines the straight and non-straight configurations of the pipeline. In the straight paths, the robot follows a linear quadratic regulator (LQR) and proportional-integral-derivative (PID) based controller that stabilizes the robot and tracks a desired velocity. In non-straight paths, the robot follows the trajectory that a motion trajectory generator block plans for the robot. The proposed method is a promising solution for smart navigation without the need for wireless communication and capable of inspecting long distances in water distribution systems.

Design, Characterization, and Control of a Size Adaptable In-pipe Robot for Water Distribution Systems

Jan 17, 2021

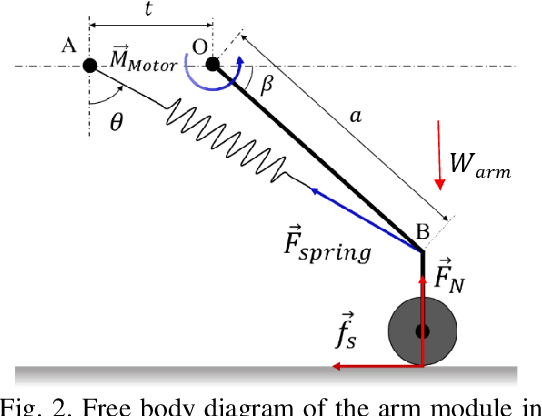

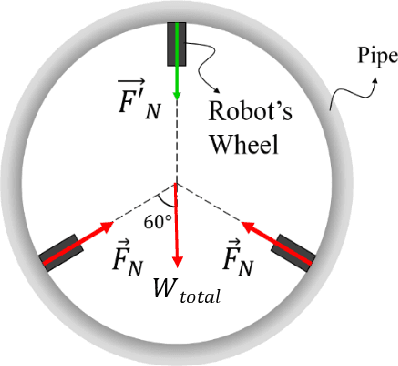

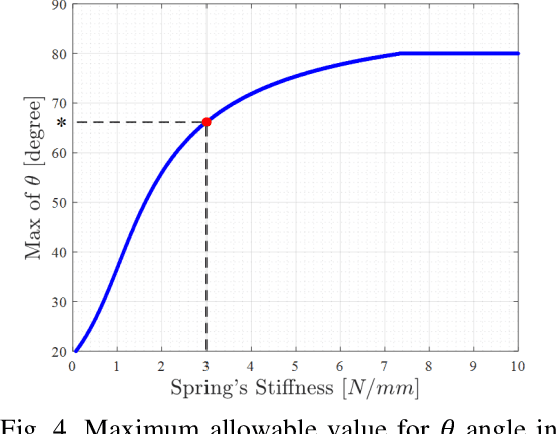

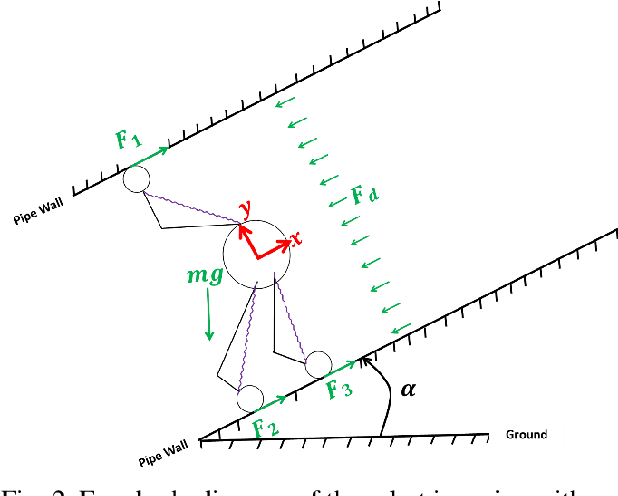

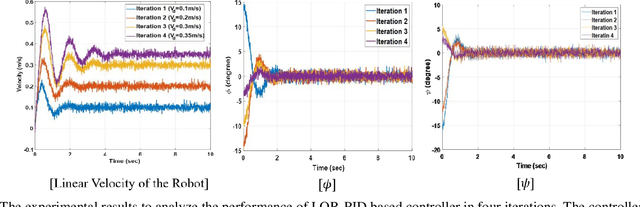

Abstract:Leak detection and water quality monitoring are requirements and challenging tasks in Water Distribution Systems (WDS). In-line robots are designed for this aim. In our previous work, we designed an in-pipe robot [1]. In this research, we present the design of the central processor, characterize and control the robot based on the condition of operation in a highly pressurized environment of pipelines with the presence of high-speed flow. To this aim, an extreme operation condition is simulated with computational fluid dynamics (CFD) and the spring mechanism is characterized to ensure sufficient stabilizing force during operation based on the extreme operating condition. Also, an end-to-end method is suggested for power considerations for our robot that calculates minimum battery capacity and operation duration in the extreme operating condition. Finally, we design a novel LQR-PID based controller based on the system auxiliary matrices that retain the robot stability inside the pipeline against disturbances and uncertainties during operation. The ADAMS-MATLAB co-simulation of the robot-controller shows the rotational velocity with -4 degree/sec and +3 degree/sec margin around x, y, and z axes while the system tracks different desired velocities in pipelines (i.e. 0.12m/s, 0.17m/s, and 0.35m/s). Also, experimental results for four iterations in a 14-inch diameter PVC pipe show that the controller brings initial values of stabilizing states to zero and oscillate around it with a margin of 2 degrees and the system tracks desired velocities of 0.1m/s, 0.2m/s, 0.3m/s, and 0.35m/s in which makes the robot dexterous in uncertain and highly disturbed the environment of pipelines during operation.

An LQR-assisted Control Algorithm for an Under-actuated In-pipe Robot in Water Distribution Systems

Dec 29, 2020

Abstract:To address the operational challenges of in-pipe robots in large pipes of water distribution systems (WDS), in this research, a control algorithm is proposed for our previously designed robot [4]. Our size adaptable robot has an under-actuated modular design that can be used for both leak detection and quality monitoring. First, nonlinear dynamical governing equations of the robot are derived with the definition of two perpendicular planes, and two sets of states are defined for the robot for stabilization and mobilization. For stabilization, we calculated the auxiliary system matrices and designed a stabilizer controller based on the linear quadratic regulator (LQR) controller, and combined it with a proportional-integral-derivative (PID) based controller for mobilization. The controller scheme is validated with simulation in MATLAB in various operation conditions in three iterations. The simulation results show that the controller can stabilize the robot inside the pipe by converging the stabilizing states to zero and keeping them in zero with initial values between -25 degree and +25 degree and tracking velocities of 10cm/s, 30cm/s, and 50cm/s which makes the robot agile and dexterous for operation in pipelines.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge