Jongwon Kim

Automatic Detection of Injection and Press Mold Parts on 2D Drawing Using Deep Neural Network

Oct 22, 2021

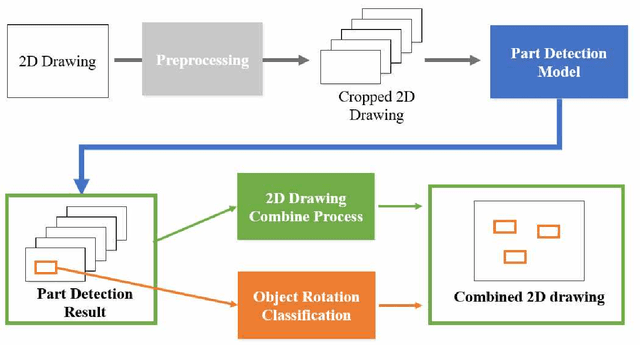

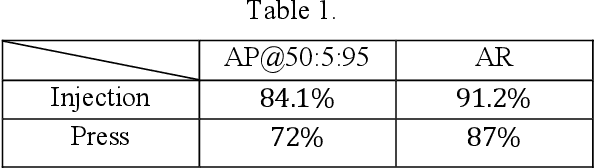

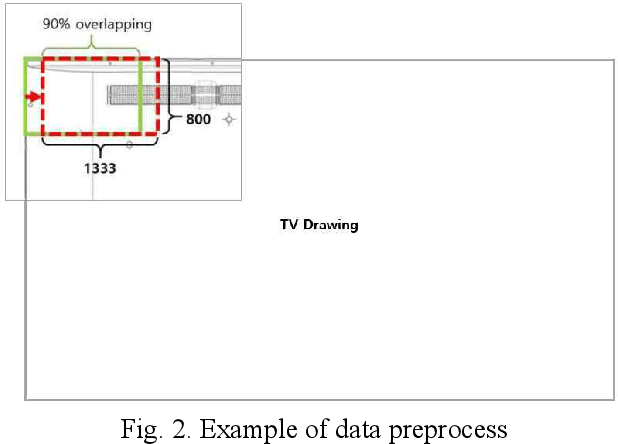

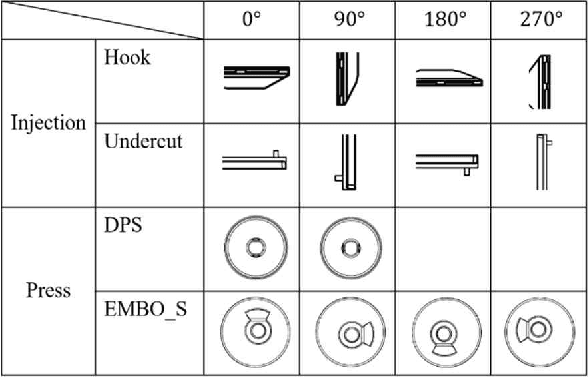

Abstract:This paper proposes a method to automatically detect the key feature parts in a CAD of commercial TV and monitor using a deep neural network. We developed a deep learning pipeline that can detect the injection parts such as hook, boss, undercut and press parts such as DPS, Embo-Screwless, Embo-Burring, and EMBO in the 2D CAD drawing images. We first cropped the drawing to a specific size for the training efficiency of a deep neural network. Then, we use Cascade R-CNN to find the position of injection and press parts and use Resnet-50 to predict the orientation of the parts. Finally, we convert the position of the parts found through the cropped image to the position of the original image. As a result, we obtained detection accuracy of injection and press parts with 84.1% in AP (Average Precision), 91.2% in AR(Average Recall), 72.0% in AP, 87.0% in AR, and orientation accuracy of injection and press parts with 94.4% and 92.0%, which can facilitate the faster design in industrial product design.

Multiple Classification with Split Learning

Sep 11, 2020

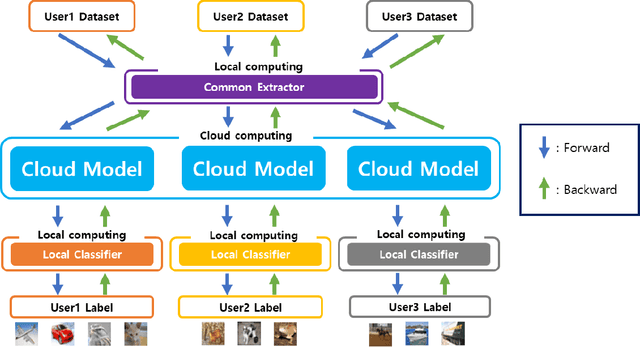

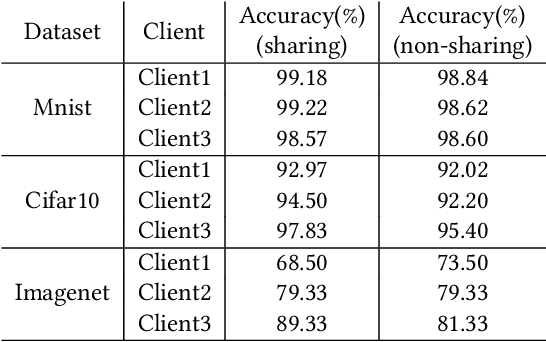

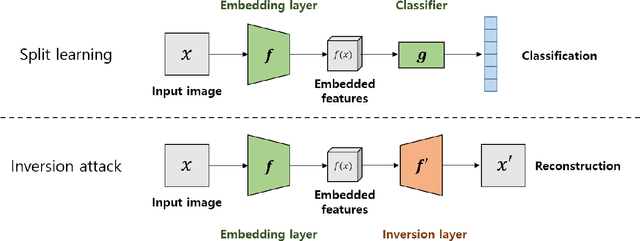

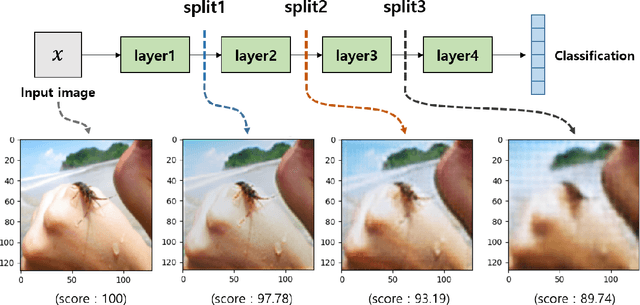

Abstract:Privacy issues were raised in the process of training deep learning in medical, mobility, and other fields. To solve this problem, we present privacy-preserving distributed deep learning method that allow clients to learn a variety of data without direct exposure. We divided a single deep learning architecture into a common extractor, a cloud model and a local classifier for the distributed learning. First, the common extractor, which is used by local clients, extracts secure features from the input data. The secure features also take the role that the cloud model can employ various task and diverse types of data. The feature contain the most important information that helps to proceed various task. Second, the cloud model including most parts of the whole training model gets the embedded features from the massive local clients, and performs most of deep learning operations which takes severe computing cost. After the operations in cloud model finished, outputs of the cloud model send back to local clients. Finally, the local classifier determined classification results and delivers the results to local clients. When clients train models, our model does not directly expose sensitive information to exterior network. During the test, the average performance improvement was 2.63% over the existing local training model. However, in a distributed environment, there is a possibility of inversion attack due to exposed features. For this reason, we experimented with the common extractor to prevent data restoration. The quality of restoration of the original image was tested by adjusting the depth of the common extractor. As a result, we found that the deeper the common extractor, the restoration score decreased to 89.74.

Segmenting Unseen Industrial Components in a Heavy Clutter Using RGB-D Fusion and Synthetic Data

Feb 11, 2020

Abstract:Segmentation of unseen industrial parts is essential for autonomous industrial systems. However, industrial components are texture-less, reflective, and often found in cluttered and unstructured environments with heavy occlusion, which makes it more challenging to deal with unseen objects. To tackle this problem, we propose a synthetic data generation pipeline that randomizes textures via domain randomization to focus on the shape information. In addition, we propose an RGB-D Fusion Mask R-CNN with a confidence map estimator, which exploits reliable depth information in multiple feature levels. We transferred the trained model to real-world scenarios and evaluated its performance by making comparisons with baselines and ablation studies. We demonstrate that our methods, which use only synthetic data, could be effective solutions for unseen industrial components segmentation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge