Jibinraj Antony

Enhancing Object Detection with Hybrid dataset in Manufacturing Environments: Comparing Federated Learning to Conventional Techniques

Aug 16, 2024

Abstract:Federated Learning (FL) has garnered significant attention in manufacturing for its robust model development and privacy-preserving capabilities. This paper contributes to research focused on the robustness of FL models in object detection, hereby presenting a comparative study with conventional techniques using a hybrid dataset for small object detection. Our findings demonstrate the superior performance of FL over centralized training models and different deep learning techniques when tested on test data recorded in a different environment with a variety of object viewpoints, lighting conditions, cluttered backgrounds, etc. These results highlight the potential of FL in achieving robust global models that perform efficiently even in unseen environments. The study provides valuable insights for deploying resilient object detection models in manufacturing environments.

Enhancing Object Detection Performance for Small Objects through Synthetic Data Generation and Proportional Class-Balancing Technique: A Comparative Study in Industrial Scenarios

Jan 29, 2024

Abstract:Object Detection (OD) has proven to be a significant computer vision method in extracting localized class information and has multiple applications in the industry. Although many of the state-of-the-art (SOTA) OD models perform well on medium and large sized objects, they seem to under perform on small objects. In most of the industrial use cases, it is difficult to collect and annotate data for small objects, as it is time-consuming and prone to human errors. Additionally, those datasets are likely to be unbalanced and often result in an inefficient model convergence. To tackle this challenge, this study presents a novel approach that injects additional data points to improve the performance of the OD models. Using synthetic data generation, the difficulties in data collection and annotations for small object data points can be minimized and to create a dataset with balanced distribution. This paper discusses the effects of a simple proportional class-balancing technique, to enable better anchor matching of the OD models. A comparison was carried out on the performances of the SOTA OD models: YOLOv5, YOLOv7 and SSD, for combinations of real and synthetic datasets within an industrial use case.

Toward Fault Detection in Industrial Welding Processes with Deep Learning and Data Augmentation

Jun 18, 2021

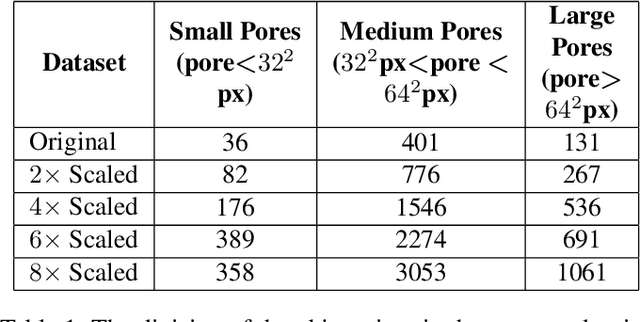

Abstract:With the rise of deep learning models in the field of computer vision, new possibilities for their application in industrial processes proves to return great benefits. Nevertheless, the actual fit of machine learning for highly standardised industrial processes is still under debate. This paper addresses the challenges on the industrial realization of the AI tools, considering the use case of Laser Beam Welding quality control as an example. We use object detection algorithms from the TensorFlow object detection API and adapt them to our use case using transfer learning. The baseline models we develop are used as benchmarks and evaluated and compared to models that undergo dataset scaling and hyperparameter tuning. We find that moderate scaling of the dataset via image augmentation leads to improvements in intersection over union (IoU) and recall, whereas high levels of augmentation and scaling may lead to deterioration of results. Finally, we put our results into perspective of the underlying use case and evaluate their fit.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge