Toward Fault Detection in Industrial Welding Processes with Deep Learning and Data Augmentation

Paper and Code

Jun 18, 2021

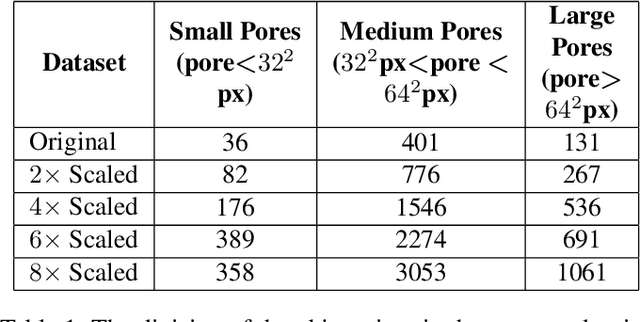

With the rise of deep learning models in the field of computer vision, new possibilities for their application in industrial processes proves to return great benefits. Nevertheless, the actual fit of machine learning for highly standardised industrial processes is still under debate. This paper addresses the challenges on the industrial realization of the AI tools, considering the use case of Laser Beam Welding quality control as an example. We use object detection algorithms from the TensorFlow object detection API and adapt them to our use case using transfer learning. The baseline models we develop are used as benchmarks and evaluated and compared to models that undergo dataset scaling and hyperparameter tuning. We find that moderate scaling of the dataset via image augmentation leads to improvements in intersection over union (IoU) and recall, whereas high levels of augmentation and scaling may lead to deterioration of results. Finally, we put our results into perspective of the underlying use case and evaluate their fit.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge