Hsien-Chung Lin

Harnessing with Twisting: Single-Arm Deformable Linear Object Manipulation for Industrial Harnessing Task

Oct 14, 2024

Abstract:Wire-harnessing tasks pose great challenges to be automated by the robot due to the complex dynamics and unpredictable behavior of the deformable wire. Traditional methods, often reliant on dual-robot arms or tactile sensing, face limitations in adaptability, cost, and scalability. This paper introduces a novel single-robot wire-harnessing pipeline that leverages a robot's twisting motion to generate necessary wire tension for precise insertion into clamps, using only one robot arm with an integrated force/torque (F/T) sensor. Benefiting from this design, the single robot arm can efficiently apply tension for wire routing and insertion into clamps in a narrow space. Our approach is structured around four principal components: a Model Predictive Control (MPC) based on the Koopman operator for tension tracking and wire following, a motion planner for sequencing harnessing waypoints, a suite of insertion primitives for clamp engagement, and a fix-point switching mechanism for wire constraint updating. Evaluated on an industrial-level wire harnessing task, our method demonstrated superior performance and reliability over conventional approaches, efficiently handling both single and multiple wire configurations with high success rates.

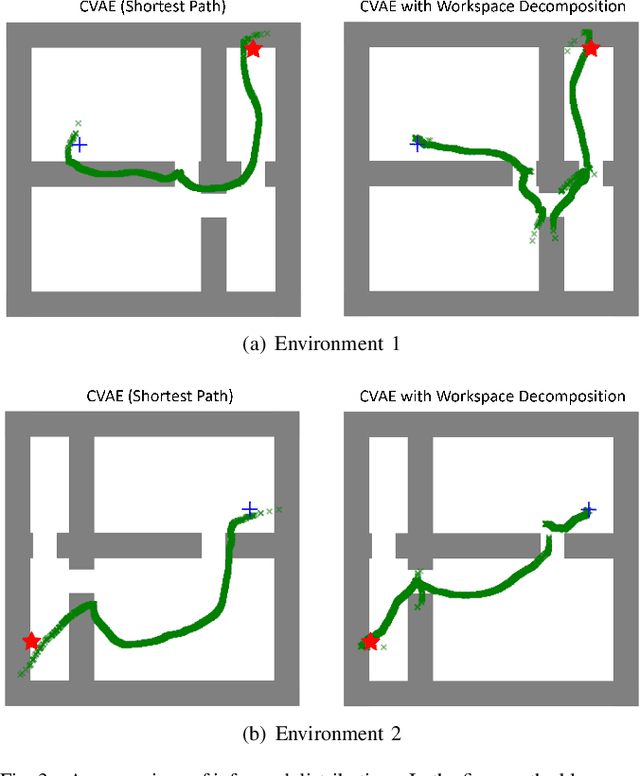

Learning from Local Experience: Informed Sampling Distributions for High Dimensional Motion Planning

Jun 15, 2023

Abstract:This paper presents a sampling-based motion planning framework that leverages the geometry of obstacles in a workspace as well as prior experiences from motion planning problems. Previous studies have demonstrated the benefits of utilizing prior solutions to motion planning problems for improving planning efficiency. However, particularly for high-dimensional systems, achieving high performance across randomized environments remains a technical challenge for experience-based approaches due to the substantial variance between each query. To address this challenge, we propose a novel approach that involves decoupling the problem into subproblems through algorithmic workspace decomposition and graph search. Additionally, we capitalize on prior experience within each subproblem. This approach effectively reduces the variance across different problems, leading to improved performance for experience-based planners. To validate the effectiveness of our framework, we conduct experiments using 2D and 6D robotic systems. The experimental results demonstrate that our framework outperforms existing algorithms in terms of planning time and cost.

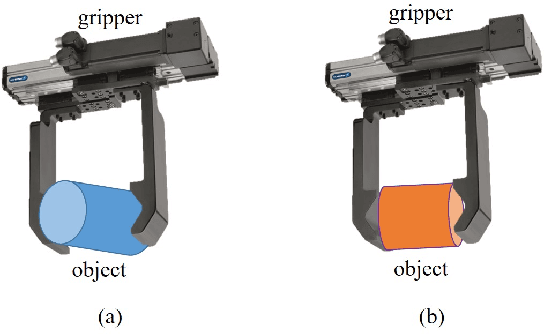

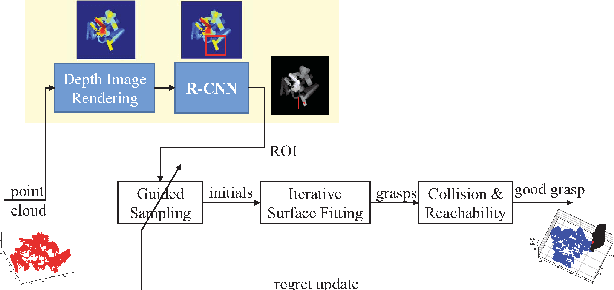

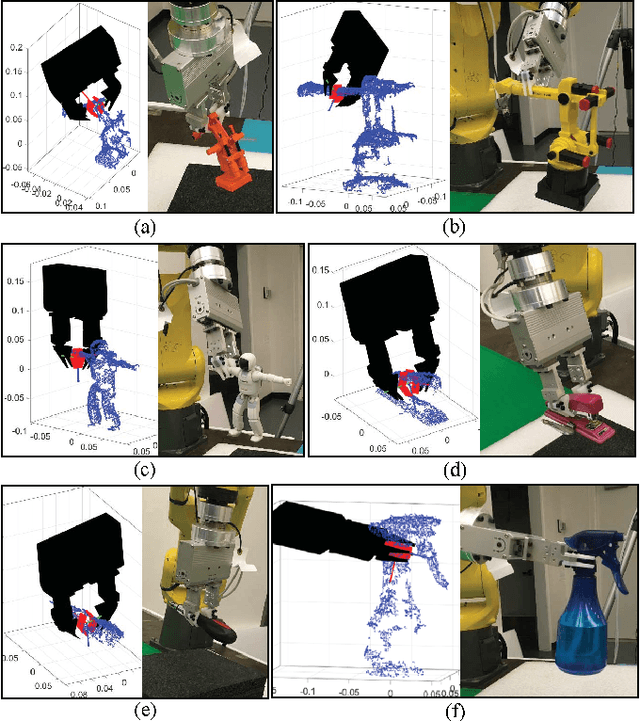

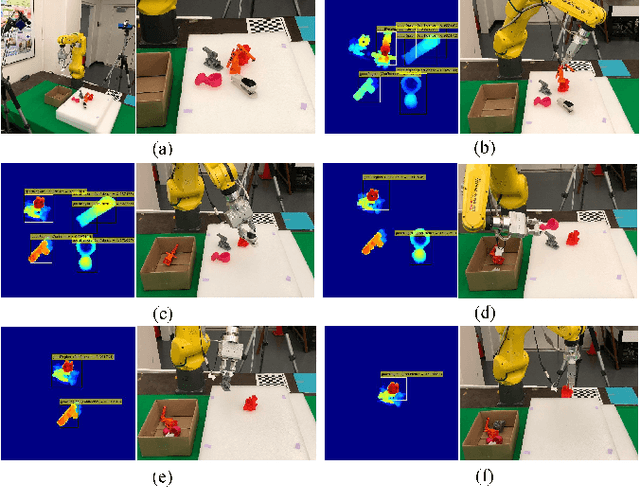

A Learning Framework for Robust Bin Picking by Customized Grippers

Mar 05, 2019

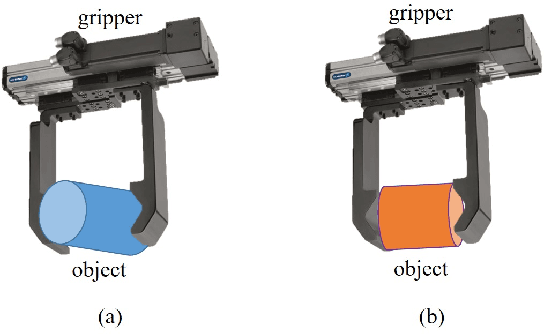

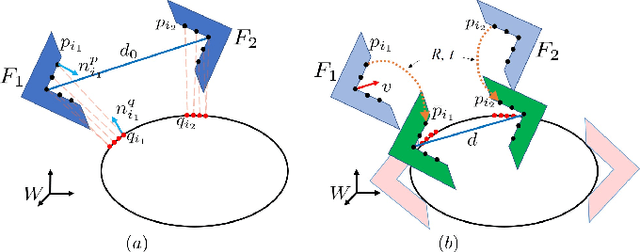

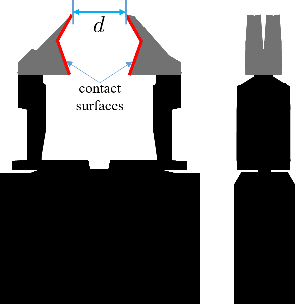

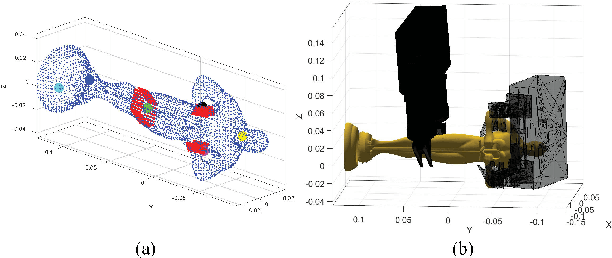

Abstract:Customized grippers have specifically designed fingers to increase the contact area with the workpieces and improve the grasp robustness. However, grasp planning for customized grippers is challenging due to the object variations, surface contacts and structural constraints of the grippers. In this paper, we propose a learning framework to plan robust grasps for customized grippers in real-time. The learning framework contains a low-level optimization-based planner to search for optimal grasps locally under object shape variations, and a high-level learning-based explorer to learn the grasp exploration based on previous grasp experience. The optimization-based planner uses an iterative surface fitting (ISF) to simultaneously search for optimal gripper transformation and finger displacement by minimizing the surface fitting error. The high-level learning-based explorer trains a region-based convolutional neural network (R-CNN) to propose good optimization regions, which avoids ISF getting stuck in bad local optima and improves the collision avoidance performance. The proposed learning framework with RCNN-ISF is able to consider the structural constraints of the gripper, learn grasp exploration strategy from previous experience, and plan optimal grasps in clutter environment in real-time. The effectiveness of the algorithm is verified by experiments.

Efficient Trajectory Optimization for Robot Motion Planning

Oct 09, 2018

Abstract:Motion planning for multi-jointed robots is challenging. Due to the inherent complexity of the problem, most existing works decompose motion planning as easier subproblems. However, because of the inconsistent performance metrics, only sub-optimal solution can be found by decomposition based approaches. This paper presents an optimal control based approach to address the path planning and trajectory planning subproblems simultaneously. Unlike similar works which either ignore robot dynamics or require long computation time, an efficient numerical method for trajectory optimization is presented in this paper for motion planning involving complicated robot dynamics. The efficiency and effectiveness of the proposed approach is shown by numerical results. Experimental results are used to show the feasibility of the presented planning algorithm.

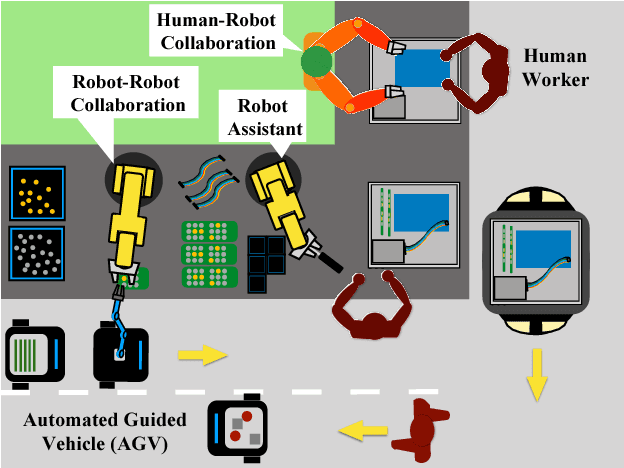

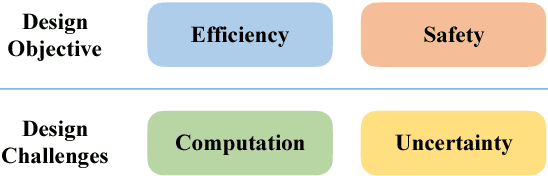

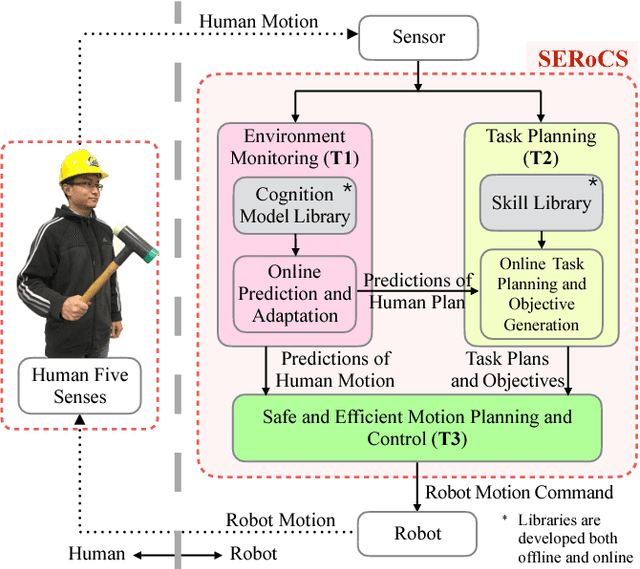

SERoCS: Safe and Efficient Robot Collaborative Systems for Next Generation Intelligent Industrial Co-Robots

Sep 21, 2018

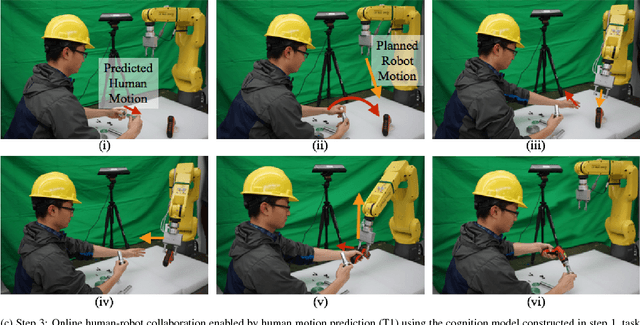

Abstract:Human-robot collaborations have been recognized as an essential component for future factories. It remains challenging to properly design the behavior of those co-robots. Those robots operate in dynamic uncertain environment with limited computation capacity. The design objective is to maximize their task efficiency while guaranteeing safety. This paper discusses a set of design principles of a safe and efficient robot collaboration system (SERoCS) for the next generation co-robots, which consists of robust cognition algorithms for environment monitoring, efficient task planning algorithms for reference generations, and safe motion planning and control algorithms for safe human-robot interactions. The proposed SERoCS will address the design challenges and significantly expand the skill sets of the co-robots to allow them to work safely and efficiently with their human counterparts. The development of SERoCS will create a significant advancement toward adoption of co-robots in various industries. The experiments validate the effectiveness of SERoCS.

Grasp Planning for Customized Grippers by Iterative Surface Fitting

Jul 28, 2018

Abstract:Customized grippers have broad applications in industrial assembly lines. Compared with general parallel grippers, the customized grippers have specifically designed fingers to increase the contact area with the workpieces and improve the grasp robustness. However, grasp planning for customized grippers is challenging due to the object variations, surface contacts and structural constraints of the grippers. In this paper, an iterative surface fitting (ISF) algorithm is proposed to plan grasps for customized grippers. ISF simultaneously searches for optimal gripper transformation and finger displacement by minimizing the surface fitting error. A guided sampling is introduced to avoid ISF getting stuck in local optima and improve the collision avoidance performance. The proposed algorithm is able to consider the structural constraints of the gripper and plan optimal grasps in real-time. The effectiveness of the algorithm is verified by both simulations and experiments. The experimental videos are available at: http://me.berkeley.edu/\%7Eyongxiangfan/CASE2018/caseisf.html

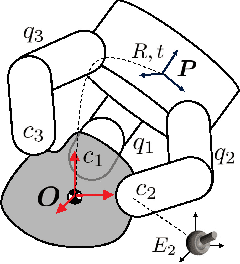

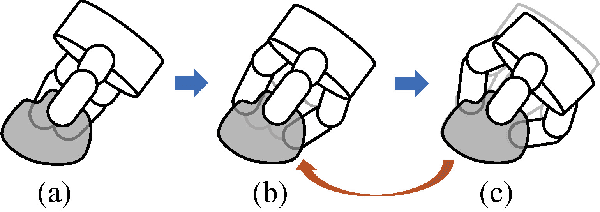

Real-Time Grasp Planning for Multi-Fingered Hands by Finger Splitting

Jul 28, 2018

Abstract:Grasp planning for multi-fingered hands is computationally expensive due to the joint-contact coupling, surface nonlinearities and high dimensionality, thus is generally not affordable for real-time implementations. Traditional planning methods by optimization, sampling or learning work well in planning for parallel grippers but remain challenging for multi-fingered hands. This paper proposes a strategy called finger splitting, to plan precision grasps for multi-fingered hands starting from optimal parallel grasps. The finger splitting is optimized by a dual-stage iterative optimization including a contact point optimization (CPO) and a palm pose optimization (PPO), to gradually split fingers and adjust both the contact points and the palm pose. The dual-stage optimization is able to consider both the object grasp quality and hand manipulability, address the nonlinearities and coupling, and achieve efficient convergence within one second. Simulation results demonstrate the effectiveness of the proposed approach. The simulation video is available at: http://me.berkeley.edu/\%7Eyongxiangfan/IROS2018/fingersplit.html

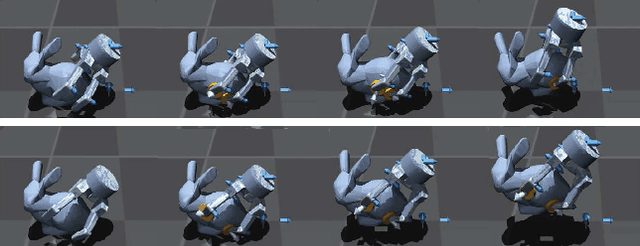

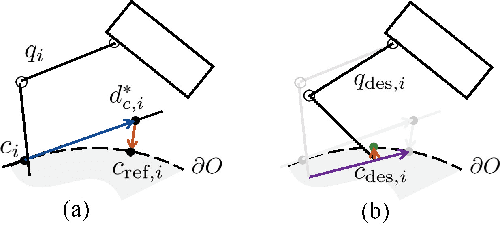

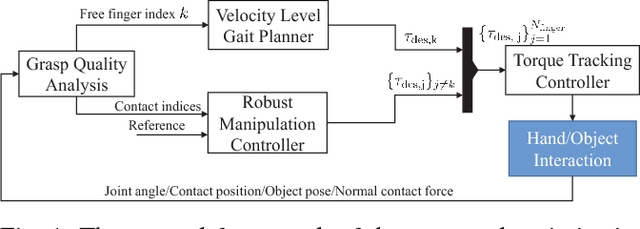

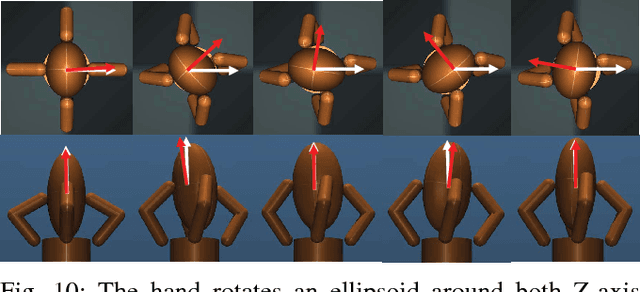

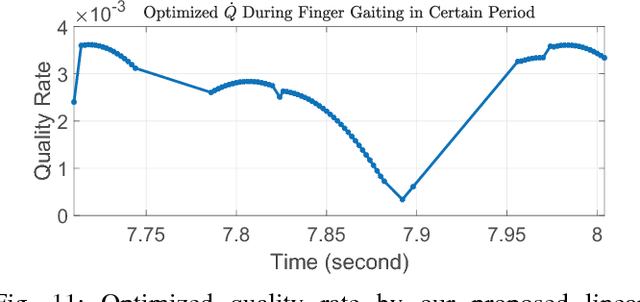

Real-Time Robust Finger Gaits Planning under Object Shape and Dynamics Uncertainties

Oct 27, 2017

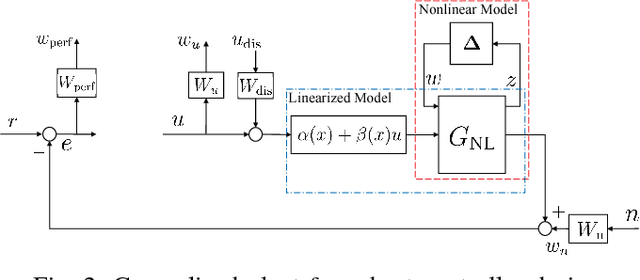

Abstract:Dexterous manipulation has broad applications in assembly lines, warehouses and agriculture. To perform large-scale manipulation tasks for various objects, a multi-fingered robotic hand sometimes has to sequentially adjust its grasping gestures, i.e. the finger gaits, to address the workspace limits and guarantee the object stability. However, realizing finger gaits planning in dexterous manipulation is challenging due to the complicated grasp quality metrics, uncertainties on object shapes and dynamics (mass and moment of inertia), and unexpected slippage under uncertain contact dynamics. In this paper, a dual-stage optimization based planner is proposed to handle these challenges. In the first stage, a velocity-level finger gaits planner is introduced by combining object grasp quality with hand manipulability. The proposed finger gaits planner is computationally efficient and realizes finger gaiting without 3D model of the object. In the second stage, a robust manipulation controller using robust control and force optimization is proposed to address object dynamics uncertainties and external disturbances. The dual-stage planner is able to guarantee stability under unexpected slippage caused by uncertain contact dynamics. Moreover, it does not require velocity measurement or expensive 3D/6D tactile sensors. The proposed dual-stage optimization based planner is verified by simulations on Mujoco.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge