Hind Haouzi

CRAN

An iterative closest point method for measuring the level of similarity of 3d log scans in wood industry

Oct 23, 2017

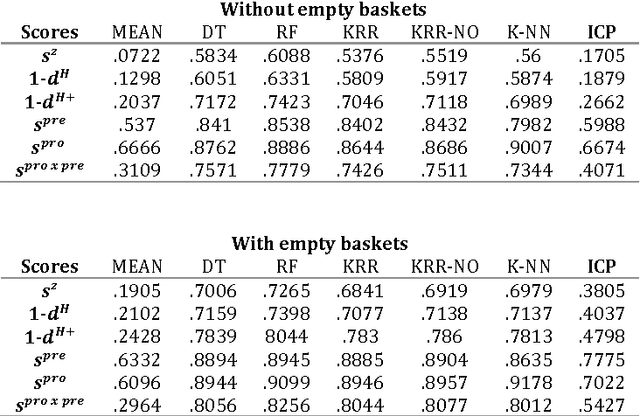

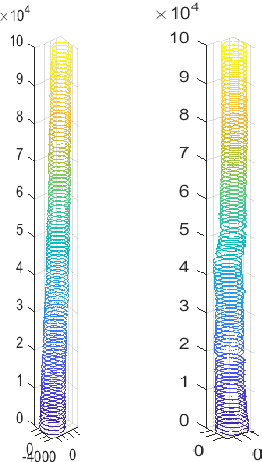

Abstract:In the Canadian's lumber industry, simulators are used to predict the lumbers resulting from the sawing of a log at a given sawmill. Giving a log or several logs' 3D scans as input, simulators perform a real-time job to predict the lumbers. These simulators, however, tend to be slow at processing large volume of wood. We thus explore an alternative approximation techniques based on the Iterative Closest Point (ICP) algorithm to identify the already processed log to which an unseen log resembles the most. The main benefit of the ICP approach is that it can easily handle 3D scans with a variable number of points. We compare this ICP-based nearest neighbor predictor, to predictors built using machine learning algorithms such as the K-nearest-neighbor (kNN) and Random Forest (RF). The implemented ICP-based predictor enabled us to identify key points in using the 3D scans directly for distance calculation. The long-term goal of this ongoing research is to integrated ICP distance calculations and machine learning.

A batching and scheduling optimisation for a cutting work-center: Acta-Mobilier case study

Oct 11, 2017

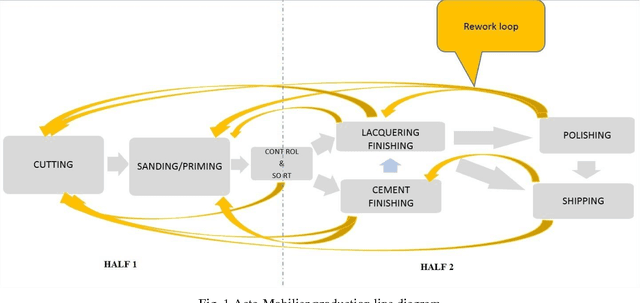

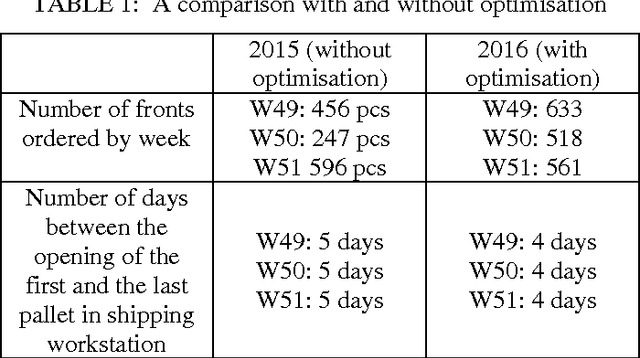

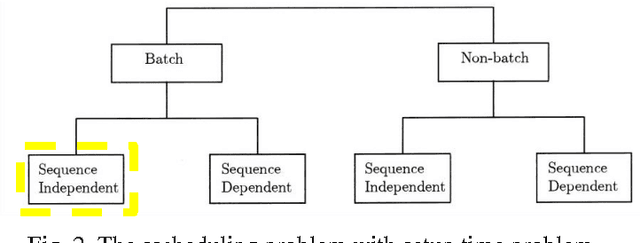

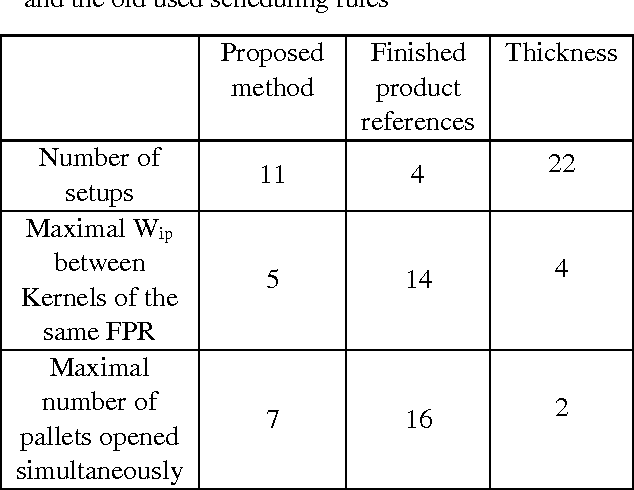

Abstract:The purpose of this study is to investigate an approach to group lots in batches and to schedule these batches on Acta-Mobilier cutting work-center while taking into account numerous constraints and objectives. The specific batching method was proposed to handle the Acta-Mobilier problem and a mathematical formalisation and genetic algorithm were proposed to deal with the scheduling problem. The proposed algorithm has been embedded in software to optimise production costs and emphasis the visual management on the production line. The application is currently being used in Acta-Mobilier plant and shows significant results

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge