Get our free extension to see links to code for papers anywhere online!Free add-on: code for papers everywhere!Free add-on: See code for papers anywhere!

Melanie Noyel

A batching and scheduling optimisation for a cutting work-center: Acta-Mobilier case study

Oct 11, 2017Figures and Tables:

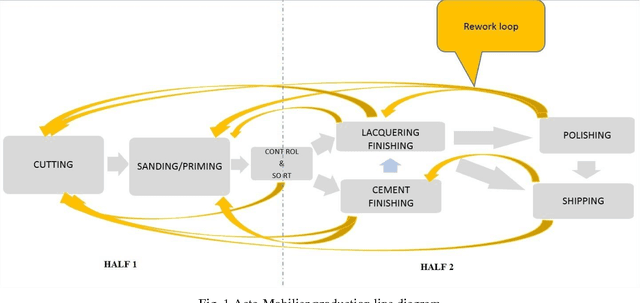

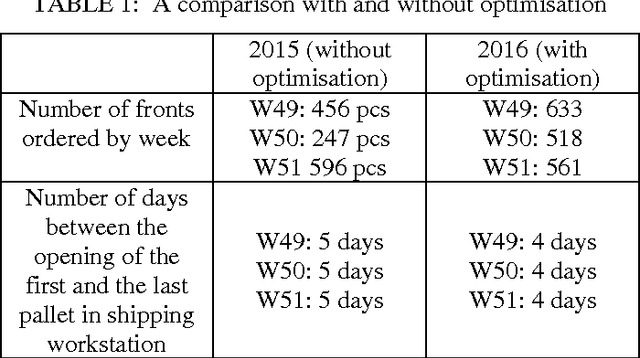

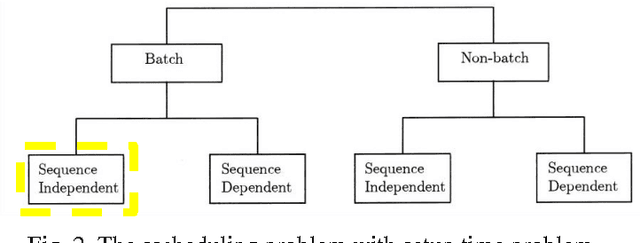

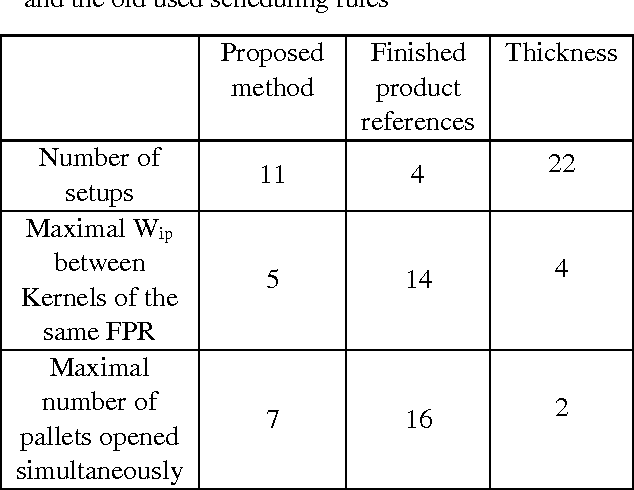

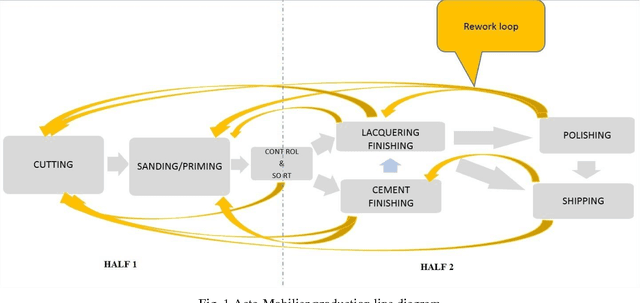

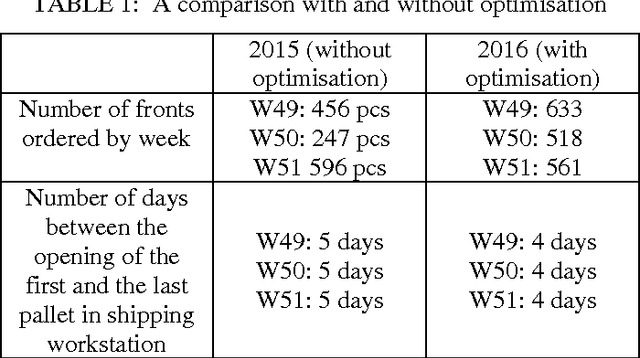

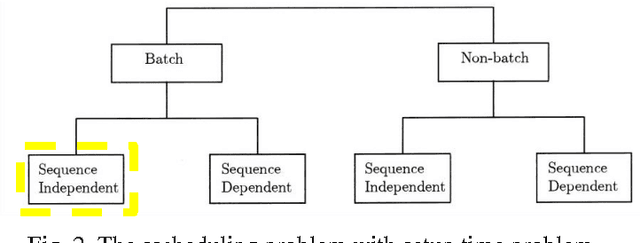

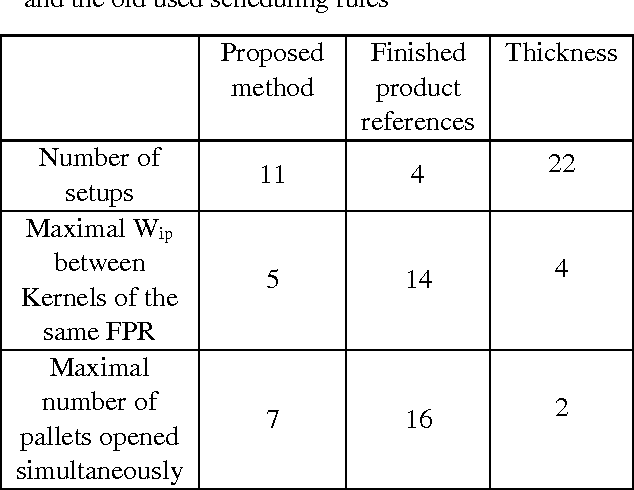

Abstract:The purpose of this study is to investigate an approach to group lots in batches and to schedule these batches on Acta-Mobilier cutting work-center while taking into account numerous constraints and objectives. The specific batching method was proposed to handle the Acta-Mobilier problem and a mathematical formalisation and genetic algorithm were proposed to deal with the scheduling problem. The proposed algorithm has been embedded in software to optimise production costs and emphasis the visual management on the production line. The application is currently being used in Acta-Mobilier plant and shows significant results

* 7th International Conference on Industrial Engineering and Systems

Management IESM'17, Oct 2017, Saarbr\"ucken, Germany

Via

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge