Michael Morin

Toward Faithful Explanations in Acoustic Anomaly Detection

Jan 19, 2026Abstract:Interpretability is essential for user trust in real-world anomaly detection applications. However, deep learning models, despite their strong performance, often lack transparency. In this work, we study the interpretability of autoencoder-based models for audio anomaly detection, by comparing a standard autoencoder (AE) with a mask autoencoder (MAE) in terms of detection performance and interpretability. We applied several attribution methods, including error maps, saliency maps, SmoothGrad, Integrated Gradients, GradSHAP, and Grad-CAM. Although MAE shows a slightly lower detection, it consistently provides more faithful and temporally precise explanations, suggesting a better alignment with true anomalies. To assess the relevance of the regions highlighted by the explanation method, we propose a perturbation-based faithfulness metric that replaces them with their reconstructions to simulate normal input. Our findings, based on experiments in a real industrial scenario, highlight the importance of incorporating interpretability into anomaly detection pipelines and show that masked training improves explanation quality without compromising performance.

Planing It by Ear: Convolutional Neural Networks for Acoustic Anomaly Detection in Industrial Wood Planers

Jan 08, 2025

Abstract:In recent years, the wood product industry has been facing a skilled labor shortage. The result is more frequent sudden failures, resulting in additional costs for these companies already operating in a very competitive market. Moreover, sawmills are challenging environments for machinery and sensors. Given that experienced machine operators may be able to diagnose defects or malfunctions, one possible way of assisting novice operators is through acoustic monitoring. As a step towards the automation of wood-processing equipment and decision support systems for machine operators, in this paper, we explore using a deep convolutional autoencoder for acoustic anomaly detection of wood planers on a new real-life dataset. Specifically, our convolutional autoencoder with skip connections (Skip-CAE) and our Skip-CAE transformer outperform the DCASE autoencoder baseline, one-class SVM, isolation forest and a published convolutional autoencoder architecture, respectively obtaining an area under the ROC curve of 0.846 and 0.875 on a dataset of real-factory planer sounds. Moreover, we show that adding skip connections and attention mechanism under the form of a transformer encoder-decoder helps to further improve the anomaly detection capabilities.

An iterative closest point method for measuring the level of similarity of 3d log scans in wood industry

Oct 23, 2017

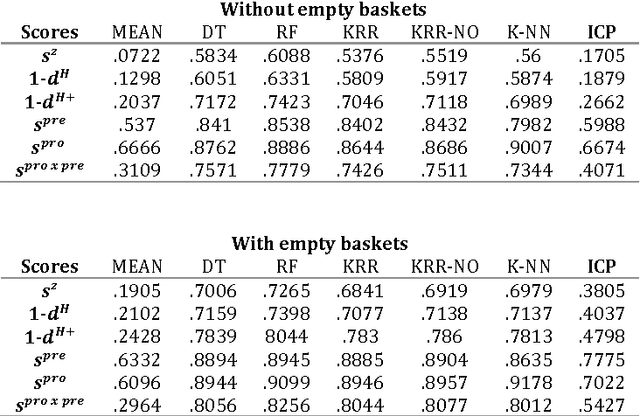

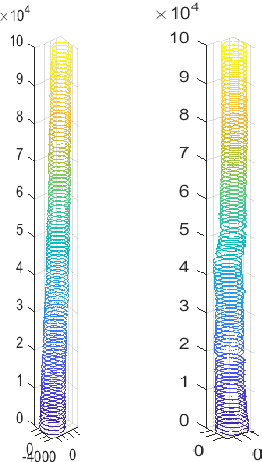

Abstract:In the Canadian's lumber industry, simulators are used to predict the lumbers resulting from the sawing of a log at a given sawmill. Giving a log or several logs' 3D scans as input, simulators perform a real-time job to predict the lumbers. These simulators, however, tend to be slow at processing large volume of wood. We thus explore an alternative approximation techniques based on the Iterative Closest Point (ICP) algorithm to identify the already processed log to which an unseen log resembles the most. The main benefit of the ICP approach is that it can easily handle 3D scans with a variable number of points. We compare this ICP-based nearest neighbor predictor, to predictors built using machine learning algorithms such as the K-nearest-neighbor (kNN) and Random Forest (RF). The implemented ICP-based predictor enabled us to identify key points in using the 3D scans directly for distance calculation. The long-term goal of this ongoing research is to integrated ICP distance calculations and machine learning.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge