Hanna Matusik

Unifying 3D Representation and Control of Diverse Robots with a Single Camera

Jul 11, 2024

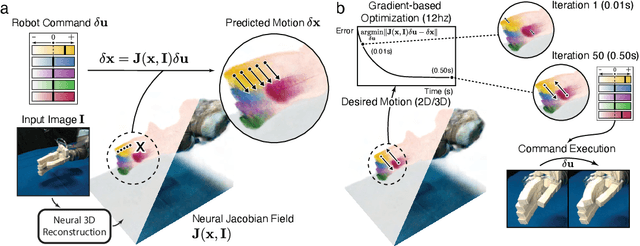

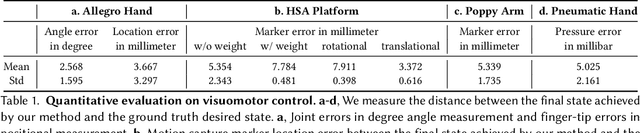

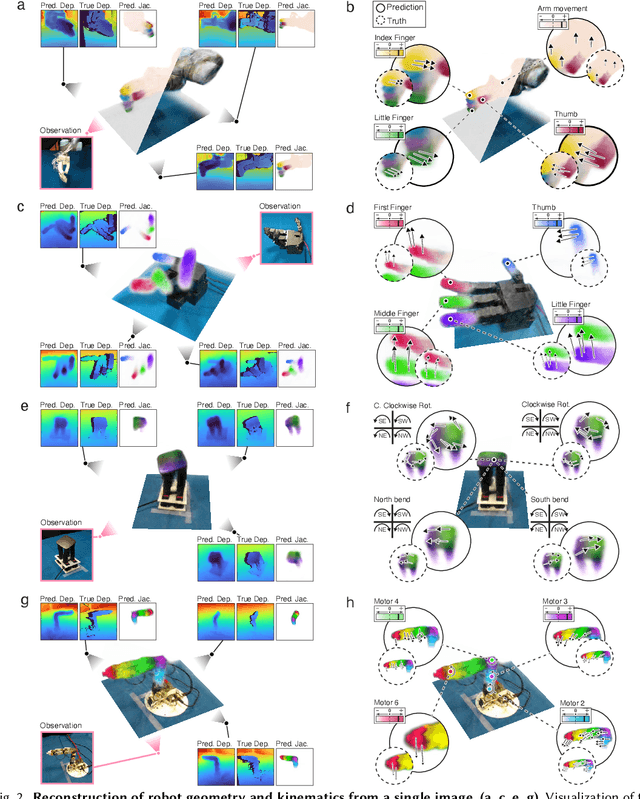

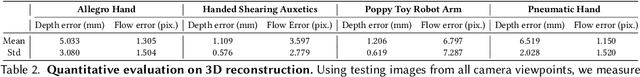

Abstract:Mirroring the complex structures and diverse functions of natural organisms is a long-standing challenge in robotics. Modern fabrication techniques have dramatically expanded feasible hardware, yet deploying these systems requires control software to translate desired motions into actuator commands. While conventional robots can easily be modeled as rigid links connected via joints, it remains an open challenge to model and control bio-inspired robots that are often multi-material or soft, lack sensing capabilities, and may change their material properties with use. Here, we introduce Neural Jacobian Fields, an architecture that autonomously learns to model and control robots from vision alone. Our approach makes no assumptions about the robot's materials, actuation, or sensing, requires only a single camera for control, and learns to control the robot without expert intervention by observing the execution of random commands. We demonstrate our method on a diverse set of robot manipulators, varying in actuation, materials, fabrication, and cost. Our approach achieves accurate closed-loop control and recovers the causal dynamic structure of each robot. By enabling robot control with a generic camera as the only sensor, we anticipate our work will dramatically broaden the design space of robotic systems and serve as a starting point for lowering the barrier to robotic automation.

Directly 3D Printed, Pneumatically Actuated Multi-Material Robotic Hand

Oct 25, 2023

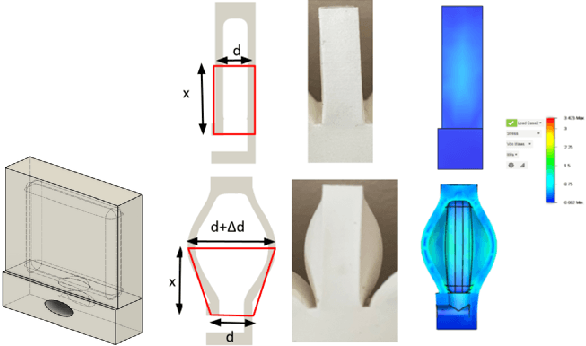

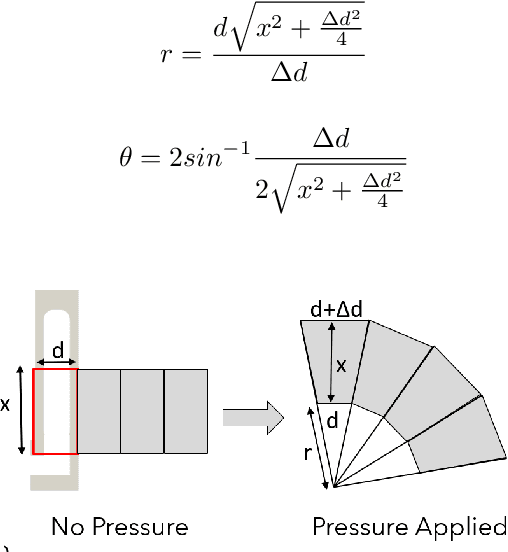

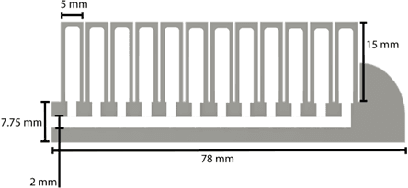

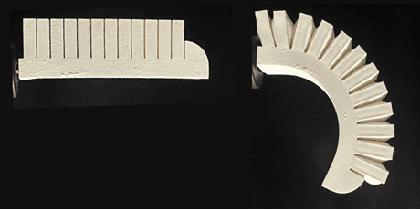

Abstract:Soft robotic manipulators with many degrees of freedom can carry out complex tasks safely around humans. However, manufacturing of soft robotic hands with several degrees of freedom requires a complex multi-step manual process, which significantly increases their cost. We present a design of a multi-material 15 DoF robotic hand with five fingers including an opposable thumb. Our design has 15 pneumatic actuators based on a series of hollow chambers that are driven by an external pressure system. The thumb utilizes rigid joints and the palm features internal rigid structure and soft skin. The design can be directly 3D printed using a multi-material additive manufacturing process without any assembly process and therefore our hand can be manufactured for less than 300 dollars. We test the hand in conjunction with a low-cost vision-based teleoperation system on different tasks.

A Modular Bio-inspired Robotic Hand with High Sensitivity

Sep 28, 2023

Abstract:While parallel grippers and multi-fingered robotic hands are well developed and commonly used in structured settings, it remains a challenge in robotics to design a highly articulated robotic hand that can be comparable to human hands to handle various daily manipulation and grasping tasks. Dexterity usually requires more actuators but also leads to a more sophisticated mechanism design and is more expensive to fabricate and maintain. Soft materials are able to provide compliance and safety when interacting with the physical world but are hard to model. This work presents a hybrid bio-inspired robotic hand that combines soft matters and rigid elements. Sensing is integrated into the rigid bodies resulting in a simple way for pose estimation with high sensitivity. The proposed hand is in a modular structure allowing for rapid fabrication and programming. The fabrication process is carefully designed so that a full hand can be made with low-cost materials and assembled in an efficient manner. We demonstrate the dexterity of the hand by successfully performing human grasp types.

* 7 pages, 13 figures, IEEE RoboSoft 2023

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge