Guru Subramani

A Method for Constraint Inference Using Pose and Wrench Measurements

Oct 29, 2020

Abstract:Many physical tasks such as pulling out a drawer or wiping a table can be modeled with geometric constraints. These geometric constraints are characterized by restrictions on kinematic trajectories and reaction wrenches (forces and moments) of objects under the influence of the constraint. This paper presents a method to infer geometric constraints involving unmodeled objects in human demonstrations using both kinematic and wrench measurements. Our approach takes a recording of a human demonstration and determines what constraints are present, when they occur, and their parameters (e.g. positions). By using both kinematic and wrench information, our methods are able to reliably identify a variety of constraint types, even if the constraints only exist for short durations within the demonstration. We present a systematic approach to fitting arbitrary scleronomic constraint models to kinematic and wrench measurements. Reaction forces are estimated from measurements by removing friction. Position, orientation, force, and moment error metrics are developed to provide systematic comparison between constraint models. By conducting a user study, we show that our methods can reliably identify constraints in realistic situations and confirm the value of including forces and moments in the model regression and selection process.

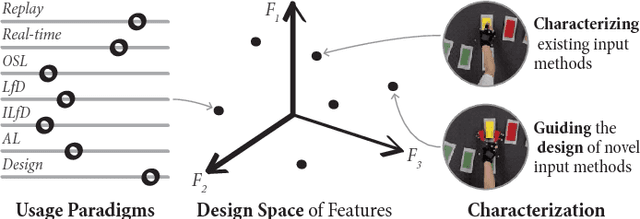

Characterizing Input Methods for Human-to-robot Demonstrations

Jan 31, 2019

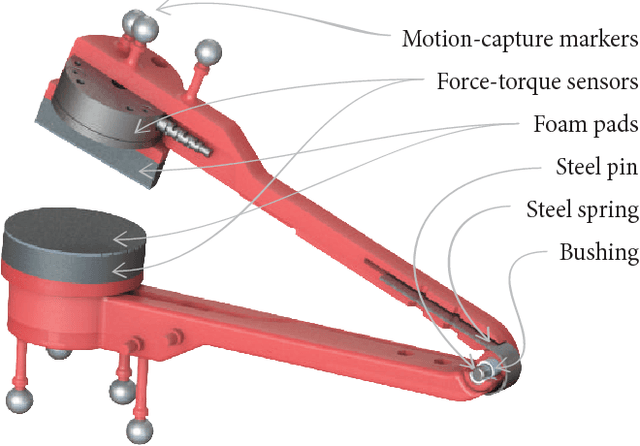

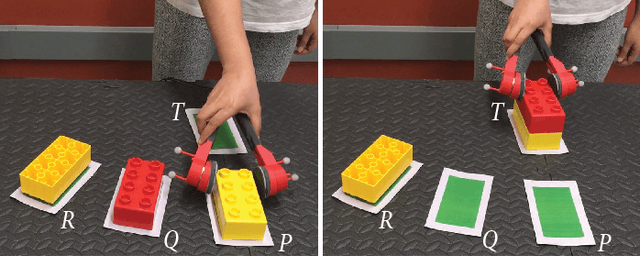

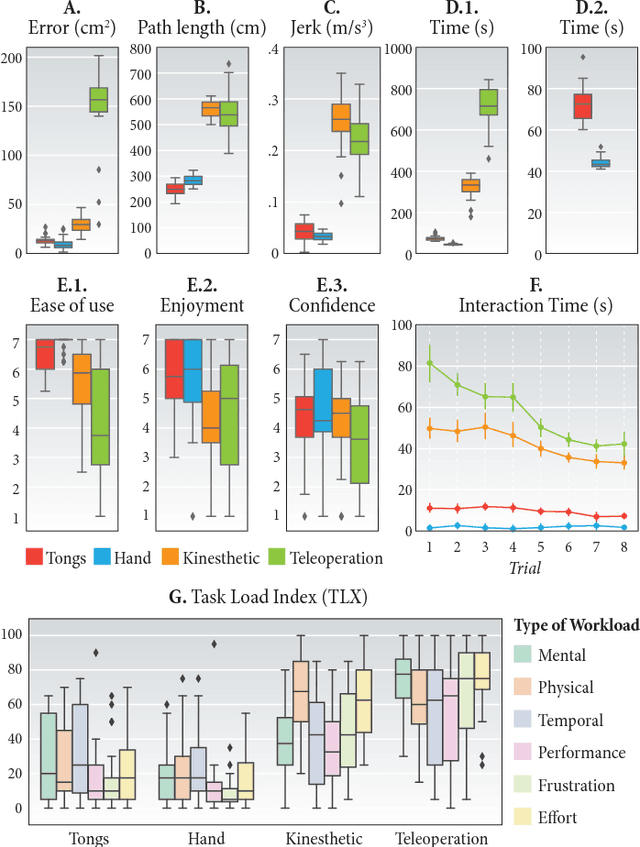

Abstract:Human demonstrations are important in a range of robotics applications, and are created with a variety of input methods. However, the design space for these input methods has not been extensively studied. In this paper, focusing on demonstrations of hand-scale object manipulation tasks to robot arms with two-finger grippers, we identify distinct usage paradigms in robotics that utilize human-to-robot demonstrations, extract abstract features that form a design space for input methods, and characterize existing input methods as well as a novel input method that we introduce, the instrumented tongs. We detail the design specifications for our method and present a user study that compares it against three common input methods: free-hand manipulation, kinesthetic guidance, and teleoperation. Study results show that instrumented tongs provide high quality demonstrations and a positive experience for the demonstrator while offering good correspondence to the target robot.

Inferring geometric constraints in human demonstrations

Sep 29, 2018

Abstract:This paper presents an approach for inferring geometric constraints in human demonstrations. In our method, geometric constraint models are built to create representations of kinematic constraints such as fixed point, axial rotation, prismatic motion, planar motion and others across multiple degrees of freedom. Our method infers geometric constraints using both kinematic and force/torque information. The approach first fits all the constraint models using kinematic information and evaluates them individually using position, force and moment criteria. Our approach does not require information about the constraint type or contact geometry; it can determine both simultaneously. We present experimental evaluations using instrumented tongs that show how constraints can be robustly inferred in recordings of human demonstrations.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge