Edoardo Romiti

A Task-Driven, Planner-in-the-Loop Computational Design Framework for Modular Manipulators

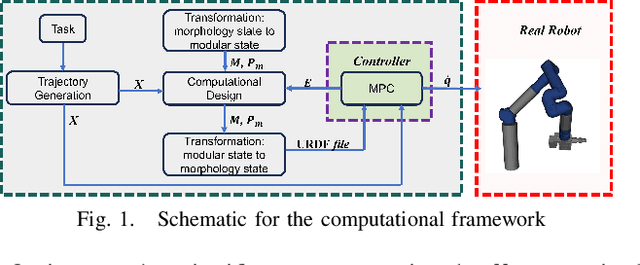

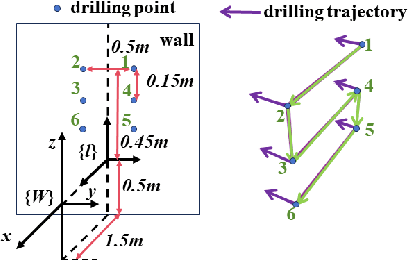

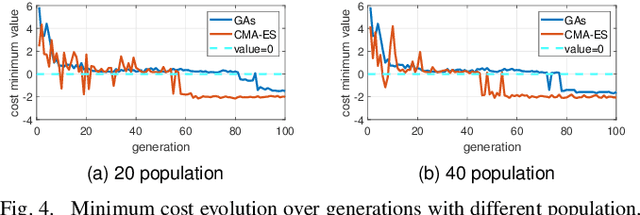

Dec 18, 2025Abstract:Modular manipulators composed of pre-manufactured and interchangeable modules offer high adaptability across diverse tasks. However, their deployment requires generating feasible motions while jointly optimizing morphology and mounted pose under kinematic, dynamic, and physical constraints. Moreover, traditional single-branch designs often extend reach by increasing link length, which can easily violate torque limits at the base joint. To address these challenges, we propose a unified task-driven computational framework that integrates trajectory planning across varying morphologies with the co-optimization of morphology and mounted pose. Within this framework, a hierarchical model predictive control (HMPC) strategy is developed to enable motion planning for both redundant and non-redundant manipulators. For design optimization, the CMA-ES is employed to efficiently explore a hybrid search space consisting of discrete morphology configurations and continuous mounted poses. Meanwhile, a virtual module abstraction is introduced to enable bi-branch morphologies, allowing an auxiliary branch to offload torque from the primary branch and extend the achievable workspace without increasing the capacity of individual joint modules. Extensive simulations and hardware experiments on polishing, drilling, and pick-and-place tasks demonstrate the effectiveness of the proposed framework. The results show that: 1) the framework can generate multiple feasible designs that satisfy kinematic and dynamic constraints while avoiding environmental collisions for given tasks; 2) flexible design objectives, such as maximizing manipulability, minimizing joint effort, or reducing the number of modules, can be achieved by customizing the cost functions; and 3) a bi-branch morphology capable of operating in a large workspace can be realized without requiring more powerful basic modules.

CONCERT: a Modular Reconfigurable Robot for Construction

Apr 07, 2025Abstract:This paper presents CONCERT, a fully reconfigurable modular collaborative robot (cobot) for multiple on-site operations in a construction site. CONCERT has been designed to support human activities in construction sites by leveraging two main characteristics: high-power density motors and modularity. In this way, the robot is able to perform a wide range of highly demanding tasks by acting as a co-worker of the human operator or by autonomously executing them following user instructions. Most of its versatility comes from the possibility of rapidly changing its kinematic structure by adding or removing passive or active modules. In this way, the robot can be set up in a vast set of morphologies, consequently changing its workspace and capabilities depending on the task to be executed. In the same way, distal end-effectors can be replaced for the execution of different operations. This paper also includes a full description of the software pipeline employed to automatically discover and deploy the robot morphology. Specifically, depending on the modules installed, the robot updates the kinematic, dynamic, and geometric parameters, taking into account the information embedded in each module. In this way, we demonstrate how the robot can be fully reassembled and made operational in less than ten minutes. We validated the CONCERT robot across different use cases, including drilling, sanding, plastering, and collaborative transportation with obstacle avoidance, all performed in a real construction site scenario. We demonstrated the robot's adaptivity and performance in multiple scenarios characterized by different requirements in terms of power and workspace. CONCERT has been designed and built by the Humanoid and Human-Centered Mechatronics Laboratory (HHCM) at the Istituto Italiano di Tecnologia in the context of the European Project Horizon 2020 CONCERT.

Task-Driven Computational Framework for Simultaneously Optimizing Design and Mounted Pose of Modular Reconfigurable Manipulators

May 03, 2024

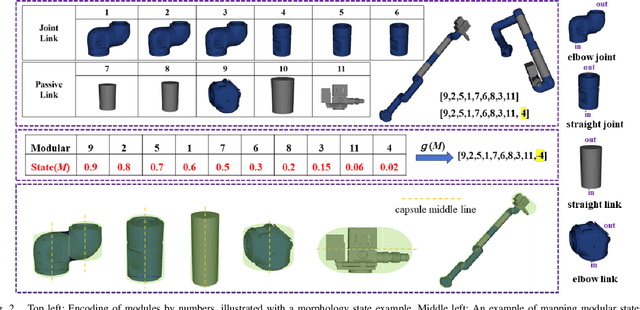

Abstract:Modular reconfigurable manipulators enable quick adaptation and versatility to address different application environments and tailor to the specific requirements of the tasks. Task performance significantly depends on the manipulator's mounted pose and morphology design, therefore posing the need of methodologies for selecting suitable modular robot configurations and mounted pose that can address the specific task requirements and required performance. Morphological changes in modular robots can be derived through a discrete optimization process involving the selective addition or removal of modules. In contrast, the adjustment of the mounted pose operates within a continuous space, allowing for smooth and precise alterations in both orientation and position. This work introduces a computational framework that simultaneously optimizes modular manipulators' mounted pose and morphology. The core of the work is that we design a mapping function that \textit{implicitly} captures the morphological state of manipulators in the continuous space. This transformation function unifies the optimization of mounted pose and morphology within a continuous space. Furthermore, our optimization framework incorporates a array of performance metrics, such as minimum joint effort and maximum manipulability, and considerations for trajectory execution error and physical and safety constraints. To highlight our method's benefits, we compare it with previous methods that framed such problem as a combinatorial optimization problem and demonstrate its practicality in selecting the modular robot configuration for executing a drilling task with the CONCERT modular robotic platform.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge