Clemens Heistracher

Towards eXplainable AI for Mobility Data Science

Jul 17, 2023Abstract:This paper presents our ongoing work towards XAI for Mobility Data Science applications, focusing on explainable models that can learn from dense trajectory data, such as GPS tracks of vehicles and vessels using temporal graph neural networks (GNNs) and counterfactuals. We review the existing GeoXAI studies, argue the need for comprehensible explanations with human-centered approaches, and outline a research path toward XAI for Mobility Data Science.

Federated Learning for Predictive Maintenance and Quality Inspection in Industrial Applications

Apr 21, 2023Abstract:Data-driven machine learning is playing a crucial role in the advancements of Industry 4.0, specifically in enhancing predictive maintenance and quality inspection. Federated learning (FL) enables multiple participants to develop a machine learning model without compromising the privacy and confidentiality of their data. In this paper, we evaluate the performance of different FL aggregation methods and compare them to central and local training approaches. Our study is based on four datasets with varying data distributions. The results indicate that the performance of FL is highly dependent on the data and its distribution among clients. In some scenarios, FL can be an effective alternative to traditional central or local training methods. Additionally, we introduce a new federated learning dataset from a real-world quality inspection setting.

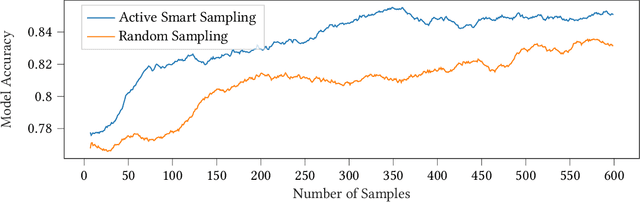

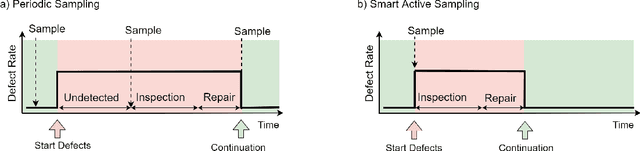

Smart Active Sampling to enhance Quality Assurance Efficiency

Sep 23, 2022

Abstract:We propose a new sampling strategy, called smart active sapling, for quality inspections outside the production line. Based on the principles of active learning a machine learning model decides which samples are sent to quality inspection. On the one hand, this minimizes the production of scrap parts due to earlier detection of quality violations. On the other hand, quality inspection costs are reduced for smooth operation.

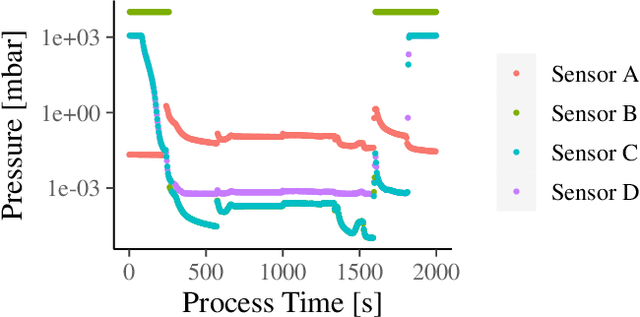

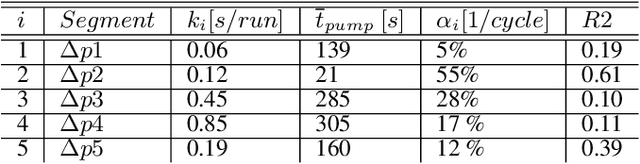

Machine Learning Methods for Health-Index Prediction in Coating Chambers

May 30, 2022

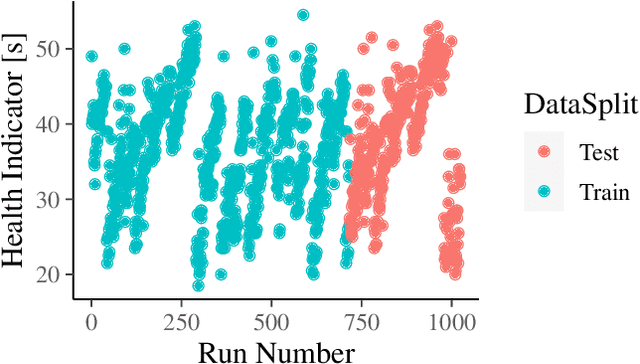

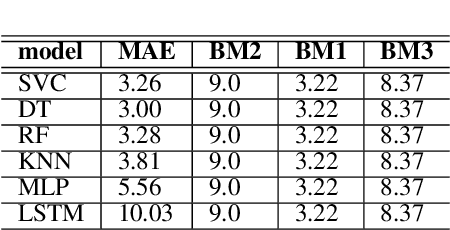

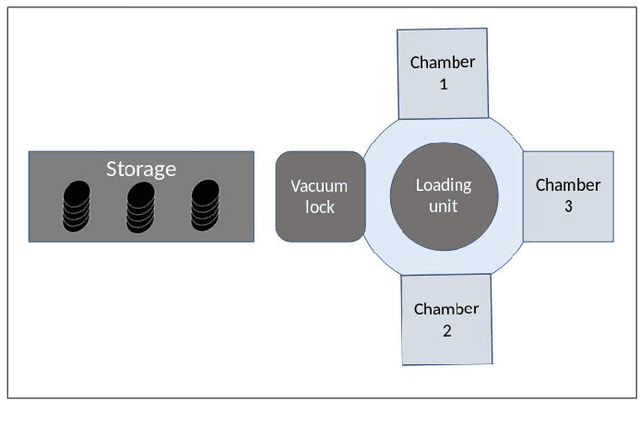

Abstract:Coating chambers create thin layers that improve the mechanical and optical surface properties in jewelry production using physical vapor deposition. In such a process, evaporated material condensates on the walls of such chambers and, over time, causes mechanical defects and unstable processes. As a result, manufacturers perform extensive maintenance procedures to reduce production loss. Current rule-based maintenance strategies neglect the impact of specific recipes and the actual condition of the vacuum chamber. Our overall goal is to predict the future condition of the coating chamber to allow cost and quality optimized maintenance of the equipment. This paper describes the derivation of a novel health indicator that serves as a step toward condition-based maintenance for coating chambers. We indirectly use gas emissions of the chamber's contamination to evaluate the machine's condition. Our approach relies on process data and does not require additional hardware installation. Further, we evaluated multiple machine learning algorithms for a condition-based forecast of the health indicator that also reflects production planning. Our results show that models based on decision trees are the most effective and outperform all three benchmarks, improving at least $0.22$ in the mean average error. Our work paves the way for cost and quality optimized maintenance of coating applications.

Minimal-Configuration Anomaly Detection for IIoT Sensors

Oct 08, 2021

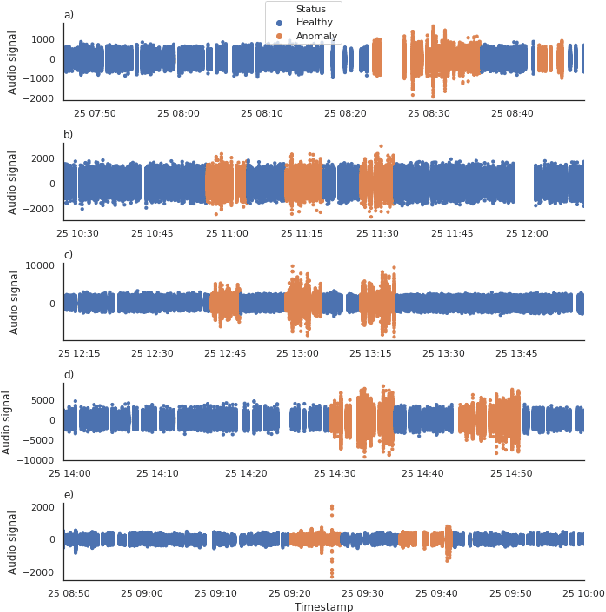

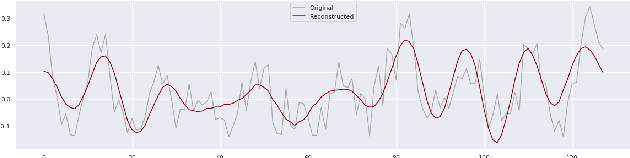

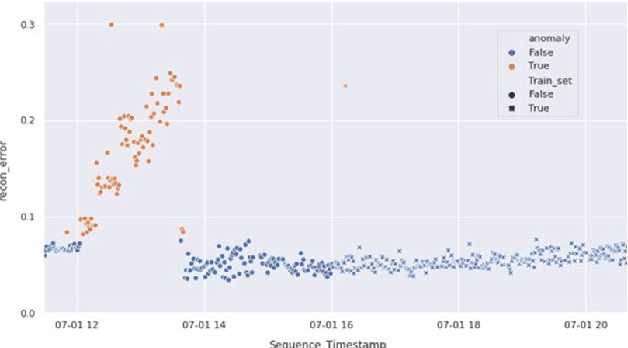

Abstract:The increasing deployment of low-cost IoT sensor platforms in industry boosts the demand for anomaly detection solutions that fulfill two key requirements: minimal configuration effort and easy transferability across equipment. Recent advances in deep learning, especially long-short-term memory (LSTM) and autoencoders, offer promising methods for detecting anomalies in sensor data recordings. We compared autoencoders with various architectures such as deep neural networks (DNN), LSTMs and convolutional neural networks (CNN) using a simple benchmark dataset, which we generated by operating a peristaltic pump under various operating conditions and inducing anomalies manually. Our preliminary results indicate that a single model can detect anomalies under various operating conditions on a four-dimensional data set without any specific feature engineering for each operating condition. We consider this work as being the first step towards a generic anomaly detection method, which is applicable for a wide range of industrial equipment.

Predicting Time-to-Failure of Plasma Etching Equipment using Machine Learning

Apr 16, 2019

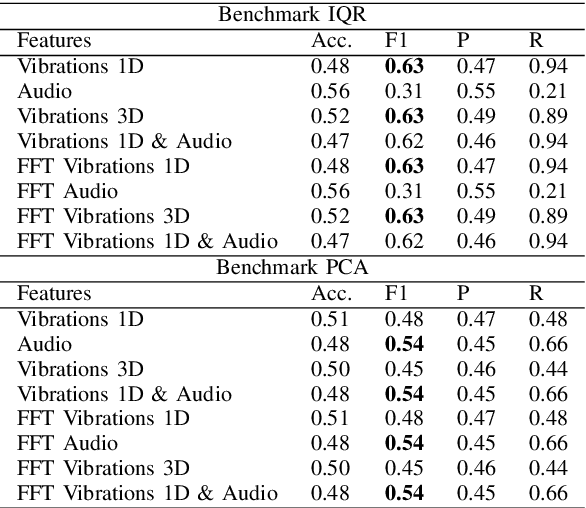

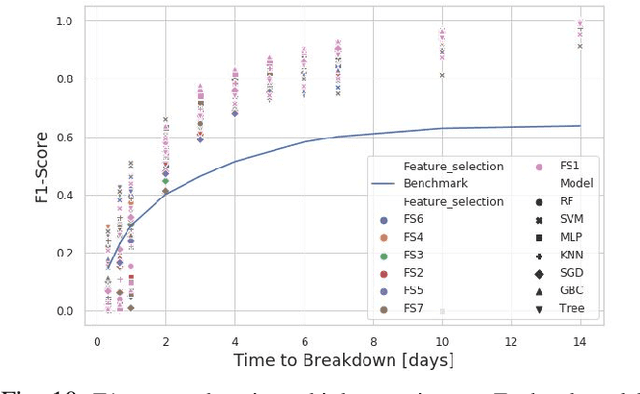

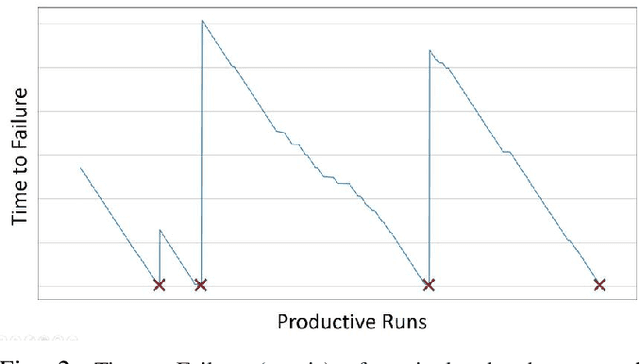

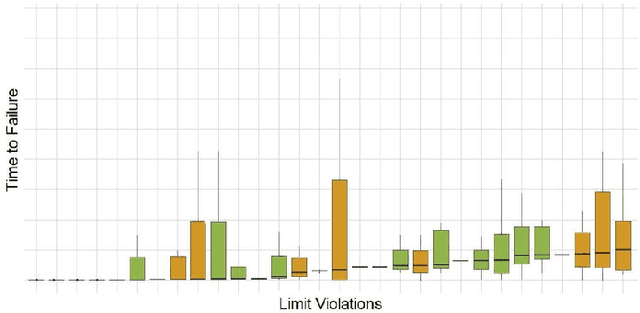

Abstract:Predicting unscheduled breakdowns of plasma etching equipment can reduce maintenance costs and production losses in the semiconductor industry. However, plasma etching is a complex procedure and it is hard to capture all relevant equipment properties and behaviors in a single physical model. Machine learning offers an alternative for predicting upcoming machine failures based on relevant data points. In this paper, we describe three different machine learning tasks that can be used for that purpose: (i) predicting Time-To-Failure (TTF), (ii) predicting health state, and (iii) predicting TTF intervals of an equipment. Our results show that trained machine learning models can outperform benchmarks resembling human judgments in all three tasks. This suggests that machine learning offers a viable alternative to currently deployed plasma etching equipment maintenance strategies and decision making processes.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge