Smart Active Sampling to enhance Quality Assurance Efficiency

Paper and Code

Sep 23, 2022

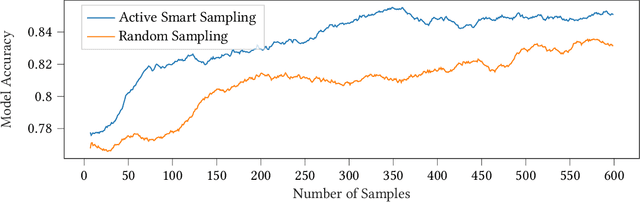

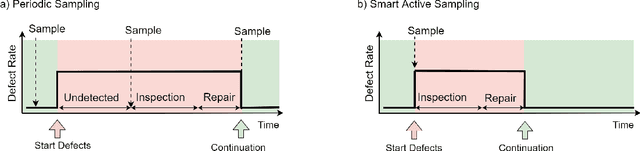

We propose a new sampling strategy, called smart active sapling, for quality inspections outside the production line. Based on the principles of active learning a machine learning model decides which samples are sent to quality inspection. On the one hand, this minimizes the production of scrap parts due to earlier detection of quality violations. On the other hand, quality inspection costs are reduced for smooth operation.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge