Chow Yin Lai

Robust Pooling through the Data Mode

Jun 21, 2021

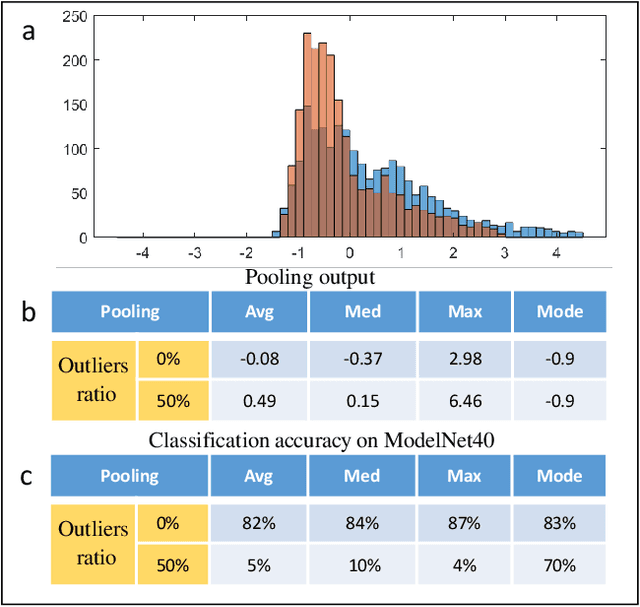

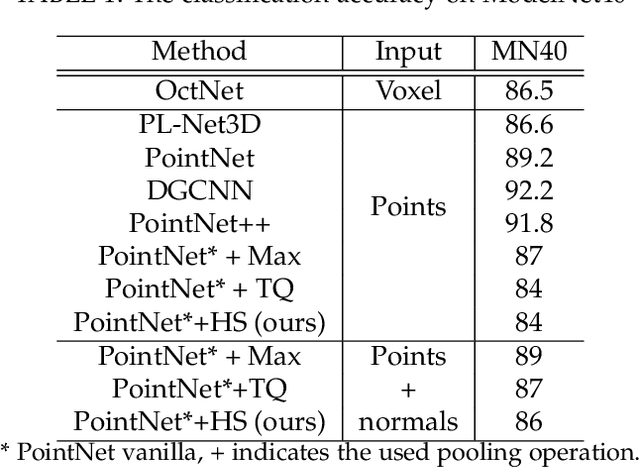

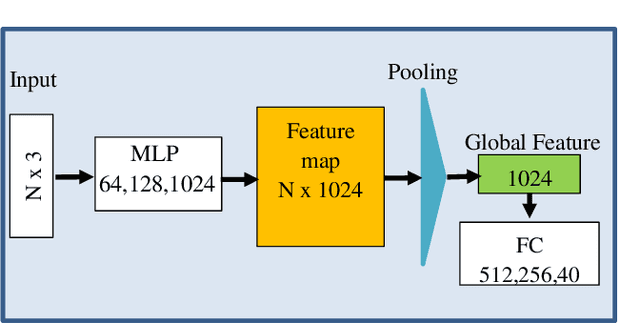

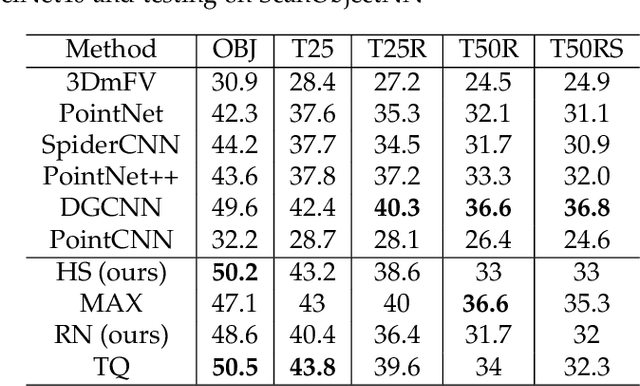

Abstract:The task of learning from point cloud data is always challenging due to the often occurrence of noise and outliers in the data. Such data inaccuracies can significantly influence the performance of state-of-the-art deep learning networks and their ability to classify or segment objects. While there are some robust deep learning approaches, they are computationally too expensive for real-time applications. This paper proposes a deep learning solution that includes a novel robust pooling layer which greatly enhances network robustness and performs significantly faster than state-of-the-art approaches. The proposed pooling layer looks for data a mode/cluster using two methods, RANSAC, and histogram, as clusters are indicative of models. We tested the pooling layer into frameworks such as Point-based and graph-based neural networks, and the tests showed enhanced robustness as compared to robust state-of-the-art methods.

Robust Object Classification Approach using Spherical Harmonics

Sep 02, 2020

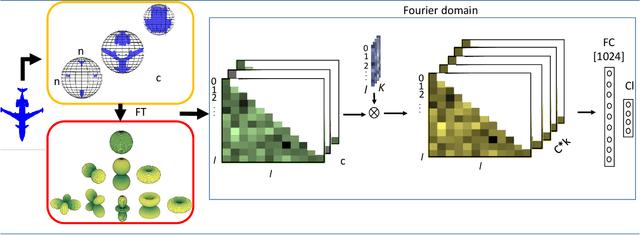

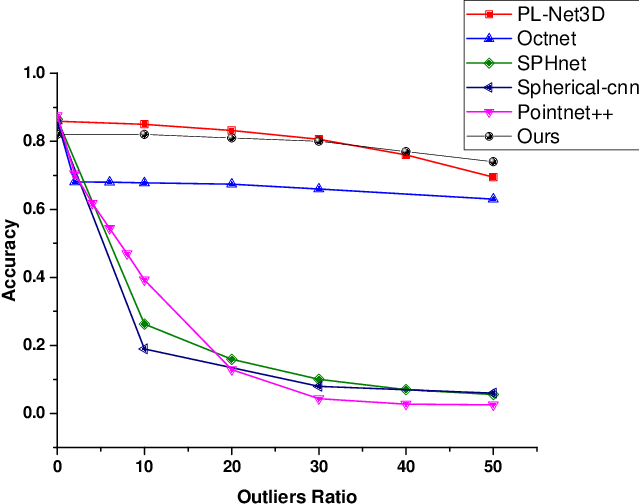

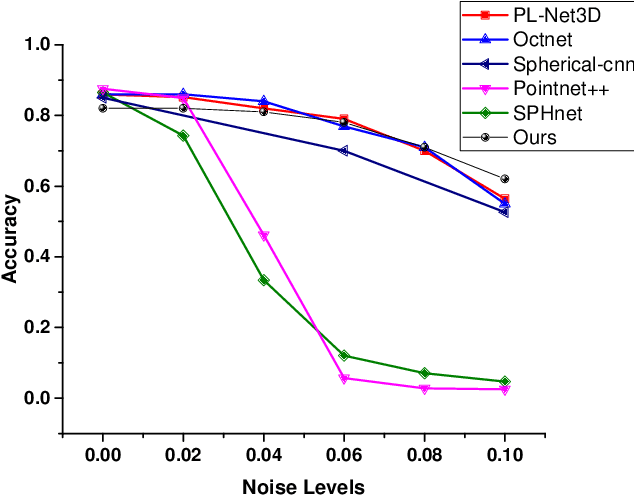

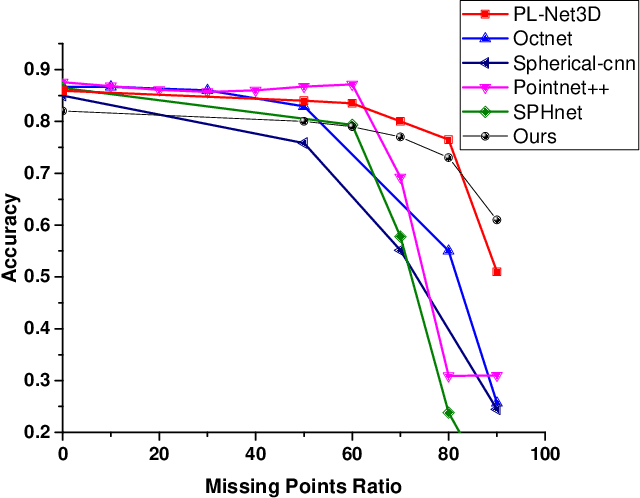

Abstract:In this paper, we present a robust spherical harmonics approach for the classification of point cloud-based objects. Spherical harmonics have been used for classification over the years, with several frameworks existing in the literature. These approaches use variety of spherical harmonics based descriptors to classify objects. We first investigated these frameworks robustness against data augmentation, such as outliers and noise, as it has not been studied before. Then we propose a spherical convolution neural network framework for robust object classification. The proposed framework uses the voxel grid of concentric spheres to learn features over the unit ball. Our proposed model learn features that are less sensitive to data augmentation due to the selected sampling strategy and the designed convolution operation. We tested our proposed model against several types of data augmentation, such as noise and outliers. Our results show that the proposed model outperforms the state of art networks in terms of robustness to data augmentation.

Metacognitive Learning Approach for Online Tool Condition Monitoring

May 06, 2017

Abstract:As manufacturing processes become increasingly automated, so should tool condition monitoring (TCM) as it is impractical to have human workers monitor the state of the tools continuously. Tool condition is crucial to ensure the good quality of products: Worn tools affect not only the surface quality but also the dimensional accuracy, which means higher reject rate of the products. Therefore, there is an urgent need to identify tool failures before it occurs on the fly. While various versions of intelligent tool condition monitoring have been proposed, most of them suffer from a cognitive nature of traditional machine learning algorithms. They focus on the how to learn process without paying attention to other two crucial issues: what to learn, and when to learn. The what to learn and the when to learn provide self regulating mechanisms to select the training samples and to determine time instants to train a model. A novel tool condition monitoring approach based on a psychologically plausible concept, namely the metacognitive scaffolding theory, is proposed and built upon a recently published algorithm, recurrent classifier (rClass). The learning process consists of three phases: what to learn, how to learn, when to learn and makes use of a generalized recurrent network structure as a cognitive component. Experimental studies with real-world manufacturing data streams were conducted where rClass demonstrated the highest accuracy while retaining the lowest complexity over its counterparts.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge