Benjamin Decardi-Nelson

University of Alberta

Generative AI and Process Systems Engineering: The Next Frontier

Feb 15, 2024

Abstract:This article explores how emerging generative artificial intelligence (GenAI) models, such as large language models (LLMs), can enhance solution methodologies within process systems engineering (PSE). These cutting-edge GenAI models, particularly foundation models (FMs), which are pre-trained on extensive, general-purpose datasets, offer versatile adaptability for a broad range of tasks, including responding to queries, image generation, and complex decision-making. Given the close relationship between advancements in PSE and developments in computing and systems technologies, exploring the synergy between GenAI and PSE is essential. We begin our discussion with a compact overview of both classic and emerging GenAI models, including FMs, and then dive into their applications within key PSE domains: synthesis and design, optimization and integration, and process monitoring and control. In each domain, we explore how GenAI models could potentially advance PSE methodologies, providing insights and prospects for each area. Furthermore, the article identifies and discusses potential challenges in fully leveraging GenAI within PSE, including multiscale modeling, data requirements, evaluation metrics and benchmarks, and trust and safety, thereby deepening the discourse on effective GenAI integration into systems analysis, design, optimization, operations, monitoring, and control. This paper provides a guide for future research focused on the applications of emerging GenAI in PSE.

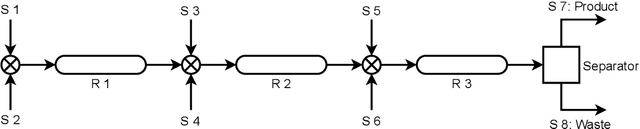

Optimizing the switching operation in monoclonal antibody production: Economic MPC and reinforcement learning

Aug 07, 2023

Abstract:Monoclonal antibodies (mAbs) have emerged as indispensable assets in medicine, and are currently at the forefront of biopharmaceutical product development. However, the growing market demand and the substantial doses required for mAb clinical treatments necessitate significant progress in its large-scale production. Most of the processes for industrial mAb production rely on batch operations, which result in significant downtime. The shift towards a fully continuous and integrated manufacturing process holds the potential to boost product yield and quality, while eliminating the extra expenses associated with storing intermediate products. The integrated continuous mAb production process can be divided into the upstream and downstream processes. One crucial aspect that ensures the continuity of the integrated process is the switching of the capture columns, which are typically chromatography columns operated in a fed-batch manner downstream. Due to the discrete nature of the switching operation, advanced process control algorithms such as economic MPC (EMPC) are computationally difficult to implement. This is because an integer nonlinear program (INLP) needs to be solved online at each sampling time. This paper introduces two computationally-efficient approaches for EMPC implementation, namely, a sigmoid function approximation approach and a rectified linear unit (ReLU) approximation approach. It also explores the application of deep reinforcement learning (DRL). These three methods are compared to the traditional switching approach which is based on a 1% product breakthrough rule and which involves no optimization.

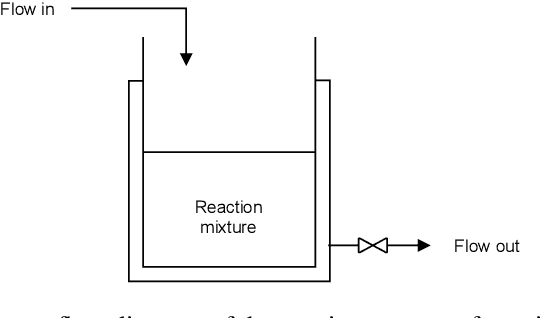

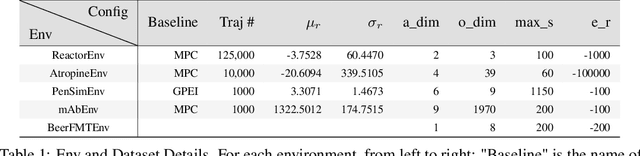

SMPL: Simulated Industrial Manufacturing and Process Control Learning Environments

Jun 17, 2022

Abstract:Traditional biological and pharmaceutical manufacturing plants are controlled by human workers or pre-defined thresholds. Modernized factories have advanced process control algorithms such as model predictive control (MPC). However, there is little exploration of applying deep reinforcement learning to control manufacturing plants. One of the reasons is the lack of high fidelity simulations and standard APIs for benchmarking. To bridge this gap, we develop an easy-to-use library that includes five high-fidelity simulation environments: BeerFMTEnv, ReactorEnv, AtropineEnv, PenSimEnv and mAbEnv, which cover a wide range of manufacturing processes. We build these environments on published dynamics models. Furthermore, we benchmark online and offline, model-based and model-free reinforcement learning algorithms for comparisons of follow-up research.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge