Ardeshir Shojaeinasab

Deep reinforcement learning for machine scheduling: Methodology, the state-of-the-art, and future directions

Oct 04, 2023Abstract:Machine scheduling aims to optimize job assignments to machines while adhering to manufacturing rules and job specifications. This optimization leads to reduced operational costs, improved customer demand fulfillment, and enhanced production efficiency. However, machine scheduling remains a challenging combinatorial problem due to its NP-hard nature. Deep Reinforcement Learning (DRL), a key component of artificial general intelligence, has shown promise in various domains like gaming and robotics. Researchers have explored applying DRL to machine scheduling problems since 1995. This paper offers a comprehensive review and comparison of DRL-based approaches, highlighting their methodology, applications, advantages, and limitations. It categorizes these approaches based on computational components: conventional neural networks, encoder-decoder architectures, graph neural networks, and metaheuristic algorithms. Our review concludes that DRL-based methods outperform exact solvers, heuristics, and tabular reinforcement learning algorithms in terms of computation speed and generating near-global optimal solutions. These DRL-based approaches have been successfully applied to static and dynamic scheduling across diverse machine environments and job characteristics. However, DRL-based schedulers face limitations in handling complex operational constraints, configurable multi-objective optimization, generalization, scalability, interpretability, and robustness. Addressing these challenges will be a crucial focus for future research in this field. This paper serves as a valuable resource for researchers to assess the current state of DRL-based machine scheduling and identify research gaps. It also aids experts and practitioners in selecting the appropriate DRL approach for production scheduling.

Synthesizing Rolling Bearing Fault Samples in New Conditions: A framework based on a modified CGAN

Jun 29, 2022

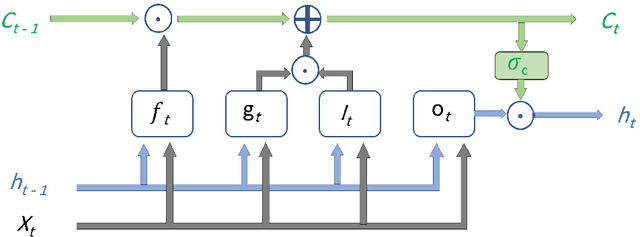

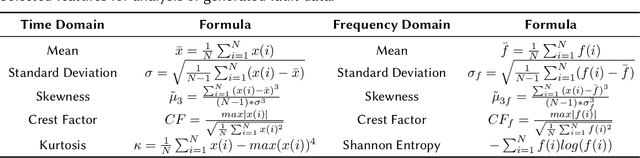

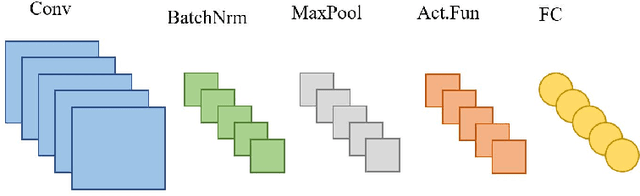

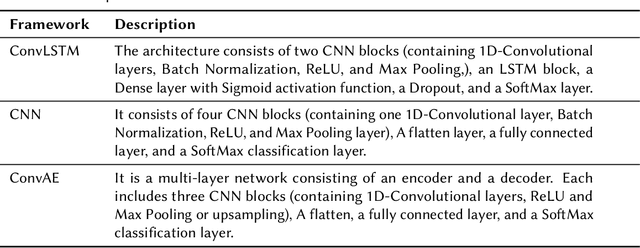

Abstract:Bearings are one of the vital components of rotating machines that are prone to unexpected faults. Therefore, bearing fault diagnosis and condition monitoring is essential for reducing operational costs and downtime in numerous industries. In various production conditions, bearings can be operated under a range of loads and speeds, which causes different vibration patterns associated with each fault type. Normal data is ample as systems usually work in desired conditions. On the other hand, fault data is rare, and in many conditions, there is no data recorded for the fault classes. Accessing fault data is crucial for developing data-driven fault diagnosis tools that can improve both the performance and safety of operations. To this end, a novel algorithm based on Conditional Generative Adversarial Networks (CGANs) is introduced. Trained on the normal and fault data on any actual fault conditions, this algorithm generates fault data from normal data of target conditions. The proposed method is validated on a real-world bearing dataset, and fault data are generated for different conditions. Several state-of-the-art classifiers and visualization models are implemented to evaluate the quality of the synthesized data. The results demonstrate the efficacy of the proposed algorithm.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge