Amil Khan

Bright 4B: Scaling Hyperspherical Learning for Segmentation in 3D Brightfield Microscopy

Dec 27, 2025Abstract:Label-free 3D brightfield microscopy offers a fast and noninvasive way to visualize cellular morphology, yet robust volumetric segmentation still typically depends on fluorescence or heavy post-processing. We address this gap by introducing Bright-4B, a 4 billion parameter foundation model that learns on the unit hypersphere to segment subcellular structures directly from 3D brightfield volumes. Bright-4B combines a hardware-aligned Native Sparse Attention mechanism (capturing local, coarse, and selected global context), depth-width residual HyperConnections that stabilize representation flow, and a soft Mixture-of-Experts for adaptive capacity. A plug-and-play anisotropic patch embed further respects confocal point-spread and axial thinning, enabling geometry-faithful 3D tokenization. The resulting model produces morphology-accurate segmentations of nuclei, mitochondria, and other organelles from brightfield stacks alone--without fluorescence, auxiliary channels, or handcrafted post-processing. Across multiple confocal datasets, Bright-4B preserves fine structural detail across depth and cell types, outperforming contemporary CNN and Transformer baselines. All code, pretrained weights, and models for downstream finetuning will be released to advance large-scale, label-free 3D cell mapping.

Deep Learning Enabled Time-Lapse 3D Cell Analysis

Aug 17, 2022

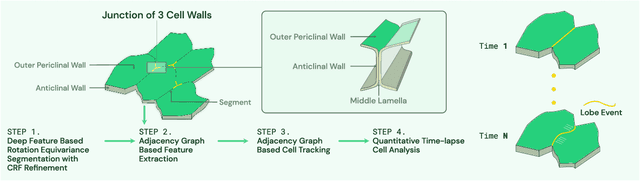

Abstract:This paper presents a method for time-lapse 3D cell analysis. Specifically, we consider the problem of accurately localizing and quantitatively analyzing sub-cellular features, and for tracking individual cells from time-lapse 3D confocal cell image stacks. The heterogeneity of cells and the volume of multi-dimensional images presents a major challenge for fully automated analysis of morphogenesis and development of cells. This paper is motivated by the pavement cell growth process, and building a quantitative morphogenesis model. We propose a deep feature based segmentation method to accurately detect and label each cell region. An adjacency graph based method is used to extract sub-cellular features of the segmented cells. Finally, the robust graph based tracking algorithm using multiple cell features is proposed for associating cells at different time instances. Extensive experiment results are provided and demonstrate the robustness of the proposed method. The code is available on Github and the method is available as a service through the BisQue portal.

3DMaterialGAN: Learning 3D Shape Representation from Latent Space for Materials Science Applications

Jul 27, 2020

Abstract:In the field of computer vision, unsupervised learning for 2D object generation has advanced rapidly in the past few years. However, 3D object generation has not garnered the same attention or success as its predecessor. To facilitate novel progress at the intersection of computer vision and materials science, we propose a 3DMaterialGAN network that is capable of recognizing and synthesizing individual grains whose morphology conforms to a given 3D polycrystalline material microstructure. This Generative Adversarial Network (GAN) architecture yields complex 3D objects from probabilistic latent space vectors with no additional information from 2D rendered images. We show that this method performs comparably or better than state-of-the-art on benchmark annotated 3D datasets, while also being able to distinguish and generate objects that are not easily annotated, such as grain morphologies. The value of our algorithm is demonstrated with analysis on experimental real-world data, namely generating 3D grain structures found in a commercially relevant wrought titanium alloy, which were validated through statistical shape comparison. This framework lays the foundation for the recognition and synthesis of polycrystalline material microstructures, which are used in additive manufacturing, aerospace, and structural design applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge