Ali Riza Durmaz

MaterioMiner -- An ontology-based text mining dataset for extraction of process-structure-property entities

Aug 05, 2024

Abstract:While large language models learn sound statistical representations of the language and information therein, ontologies are symbolic knowledge representations that can complement the former ideally. Research at this critical intersection relies on datasets that intertwine ontologies and text corpora to enable training and comprehensive benchmarking of neurosymbolic models. We present the MaterioMiner dataset and the linked materials mechanics ontology where ontological concepts from the mechanics of materials domain are associated with textual entities within the literature corpus. Another distinctive feature of the dataset is its eminently fine-granular annotation. Specifically, 179 distinct classes are manually annotated by three raters within four publications, amounting to a total of 2191 entities that were annotated and curated. Conceptual work is presented for the symbolic representation of causal composition-process-microstructure-property relationships. We explore the annotation consistency between the three raters and perform fine-tuning of pre-trained models to showcase the feasibility of named-entity recognition model training. Reusing the dataset can foster training and benchmarking of materials language models, automated ontology construction, and knowledge graph generation from textual data.

Microstructure quality control of steels using deep learning

Jun 01, 2023

Abstract:In quality control, microstructures are investigated rigorously to ensure structural integrity, exclude the presence of critical volume defects, and validate the formation of the target microstructure. For quenched, hierarchically-structured steels, the morphology of the bainitic and martensitic microstructures are of major concern to guarantee the reliability of the material under service conditions. Therefore, industries conduct small sample-size inspections of materials cross-sections through metallographers to validate the needle morphology of such microstructures. We demonstrate round-robin test results revealing that this visual grading is afflicted by pronounced subjectivity despite the thorough training of personnel. Instead, we propose a deep learning image classification approach that distinguishes steels based on their microstructure type and classifies their needle length alluding to the ISO 643 grain size assessment standard. This classification approach facilitates the reliable, objective, and automated classification of hierarchically structured steels. Specifically, an accuracy of 96% and roughly 91% is attained for the distinction of martensite/bainite subtypes and needle length, respectively. This is achieved on an image dataset that contains significant variance and labeling noise as it is acquired over more than ten years from multiple plants, alloys, etchant applications, and light optical microscopes by many metallographers (raters). Interpretability analysis gives insights into the decision-making of these models and allows for estimating their generalization capability.

Addressing materials' microstructure diversity using transfer learning

Jul 29, 2021

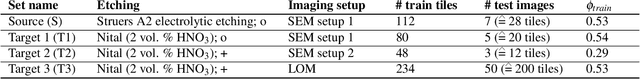

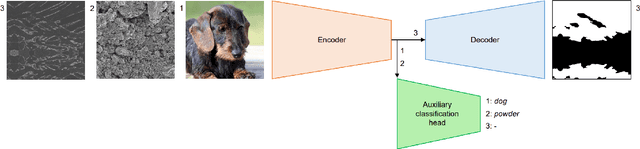

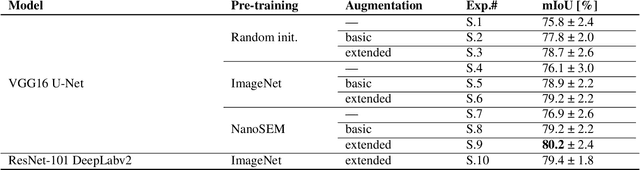

Abstract:Materials' microstructures are signatures of their alloying composition and processing history. Therefore, microstructures exist in a wide variety. As materials become increasingly complex to comply with engineering demands, advanced computer vision (CV) approaches such as deep learning (DL) inevitably gain relevance for quantifying microstrucutures' constituents from micrographs. While DL can outperform classical CV techniques for many tasks, shortcomings are poor data efficiency and generalizability across datasets. This is inherently in conflict with the expense associated with annotating materials data through experts and extensive materials diversity. To tackle poor domain generalizability and the lack of labeled data simultaneously, we propose to apply a sub-class of transfer learning methods called unsupervised domain adaptation (UDA). These algorithms address the task of finding domain-invariant features when supplied with annotated source data and unannotated target data, such that performance on the latter distribution is optimized despite the absence of annotations. Exemplarily, this study is conducted on a lath-shaped bainite segmentation task in complex phase steel micrographs. Here, the domains to bridge are selected to be different metallographic specimen preparations (surface etchings) and distinct imaging modalities. We show that a state-of-the-art UDA approach surpasses the na\"ive application of source domain trained models on the target domain (generalization baseline) to a large extent. This holds true independent of the domain shift, despite using little data, and even when the baseline models were pre-trained or employed data augmentation. Through UDA, mIoU was improved over generalization baselines from 82.2%, 61.0%, 49.7% to 84.7%, 67.3%, 73.3% on three target datasets, respectively. This underlines this techniques' potential to cope with materials variance.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge