Ah-hyeon Jin

Performance Comparison of Design Optimization and Deep Learning-based Inverse Design

Aug 23, 2023Abstract:Surrogate model-based optimization has been increasingly used in the field of engineering design. It involves creating a surrogate model with objective functions or constraints based on the data obtained from simulations or real-world experiments, and then finding the optimal solution from the model using numerical optimization methods. Recent advancements in deep learning-based inverse design methods have made it possible to generate real-time optimal solutions for engineering design problems, eliminating the requirement for iterative optimization processes. Nevertheless, no comprehensive study has yet closely examined the specific advantages and disadvantages of this novel approach compared to the traditional design optimization method. The objective of this paper is to compare the performance of traditional design optimization methods with deep learning-based inverse design methods by employing benchmark problems across various scenarios. Based on the findings of this study, we provide guidelines that can be taken into account for the future utilization of deep learning-based inverse design. It is anticipated that these guidelines will enhance the practical applicability of this approach to real engineering design problems.

Wheel Impact Test by Deep Learning: Prediction of Location and Magnitude of Maximum Stress

Oct 03, 2022

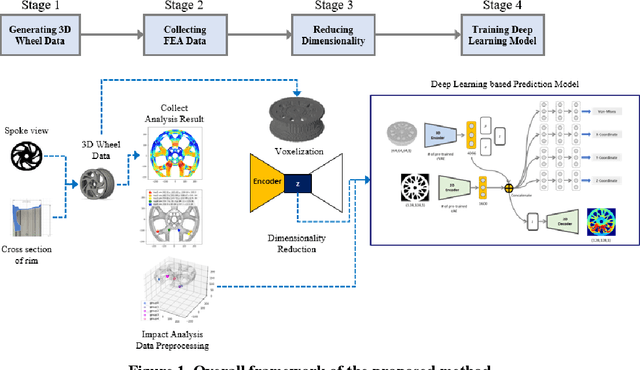

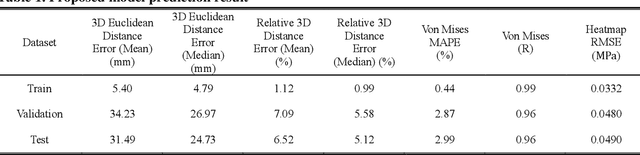

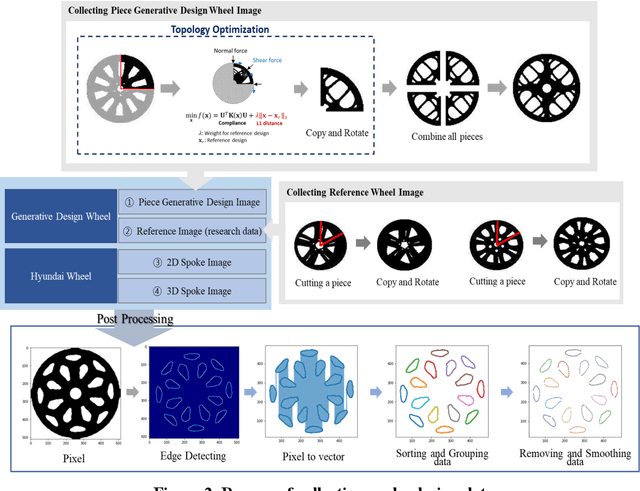

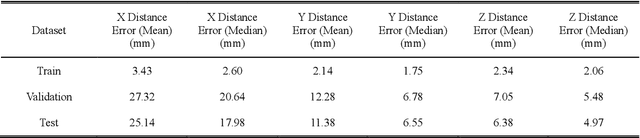

Abstract:The impact performance of the wheel during wheel development must be ensured through a wheel impact test for vehicle safety. However, manufacturing and testing a real wheel take a significant amount of time and money because developing an optimal wheel design requires numerous iterative processes of modifying the wheel design and verifying the safety performance. Accordingly, the actual wheel impact test has been replaced by computer simulations, such as Finite Element Analysis (FEA), but it still requires high computational costs for modeling and analysis. Moreover, FEA experts are needed. This study presents an aluminum road wheel impact performance prediction model based on deep learning that replaces the computationally expensive and time-consuming 3D FEA. For this purpose, 2D disk-view wheel image data, 3D wheel voxel data, and barrier mass value used for wheel impact test are utilized as the inputs to predict the magnitude of maximum von Mises stress, corresponding location, and the stress distribution of 2D disk-view. The wheel impact performance prediction model can replace the impact test in the early wheel development stage by predicting the impact performance in real time and can be used without domain knowledge. The time required for the wheel development process can be shortened through this mechanism.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge