Safely Learning Visuo-Tactile Feedback Policies in Real For Industrial Insertion

Paper and Code

Oct 04, 2022

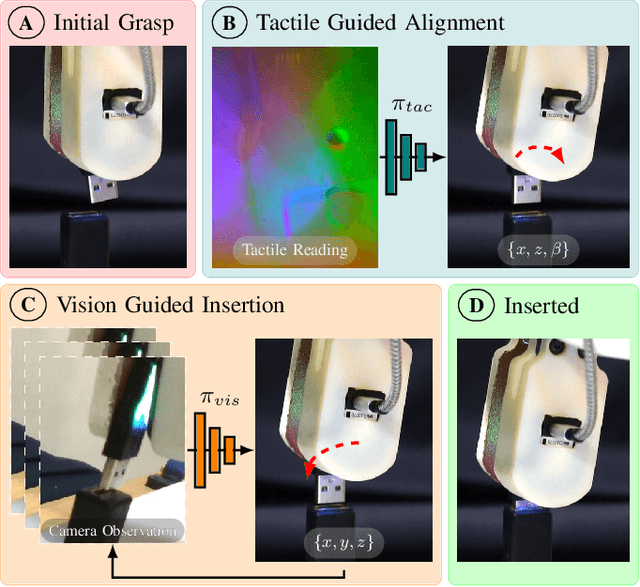

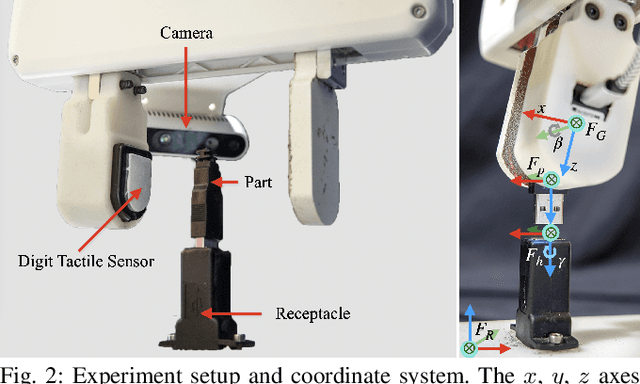

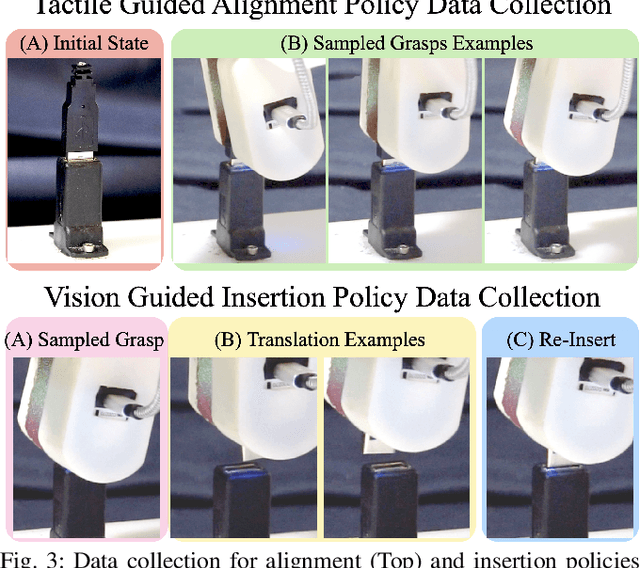

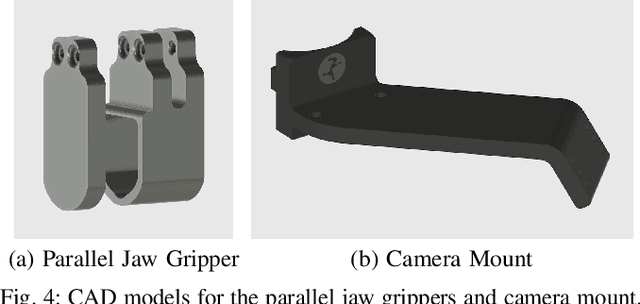

Industrial insertion tasks are often performed repetitively with parts that are subject to tight tolerances and prone to breakage. In this paper, we present a safe method to learn a visuo-tactile insertion policy that is robust against grasp pose variations while minimizing human inputs and collision between the robot and the environment. We achieve this by dividing the insertion task into two phases. In the first align phase, we learn a tactile-based grasp pose estimation model to align the insertion part with the receptacle. In the second insert phase, we learn a vision-based policy to guide the part into the receptacle. Using force-torque sensing, we also develop a safe self-supervised data collection pipeline that limits collision between the part and the surrounding environment. Physical experiments on the USB insertion task from the NIST Assembly Taskboard suggest that our approach can achieve 45/45 insertion successes on 45 different initial grasp poses, improving on two baselines: (1) a behavior cloning agent trained on 50 human insertion demonstrations (1/45) and (2) an online RL policy (TD3) trained in real (0/45).

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge