Design, Control, and Applications of a Soft Robotic Arm

Paper and Code

Jul 08, 2020

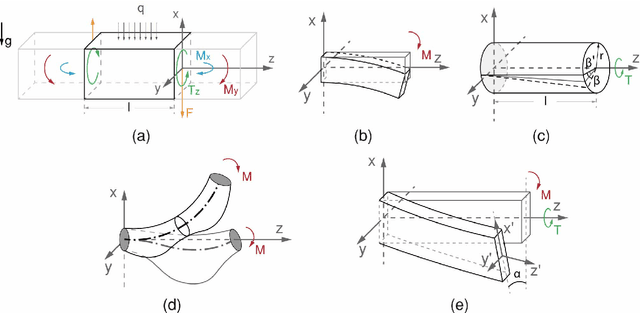

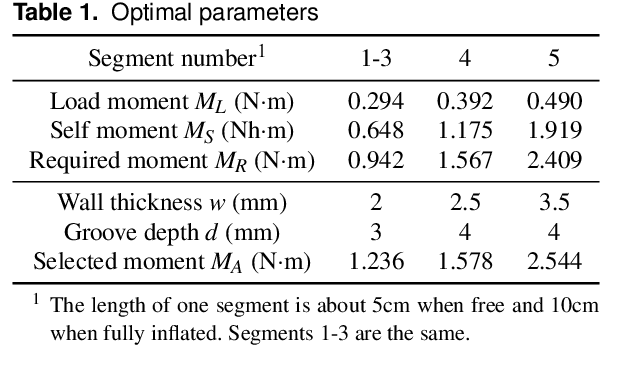

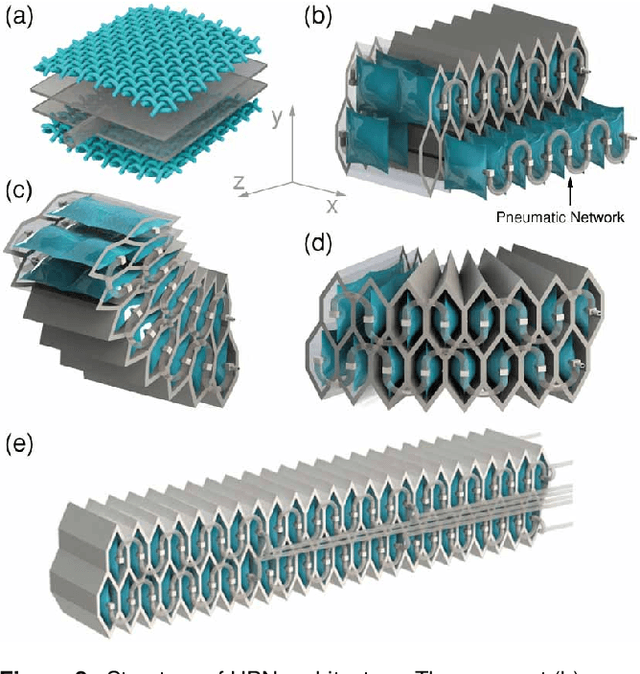

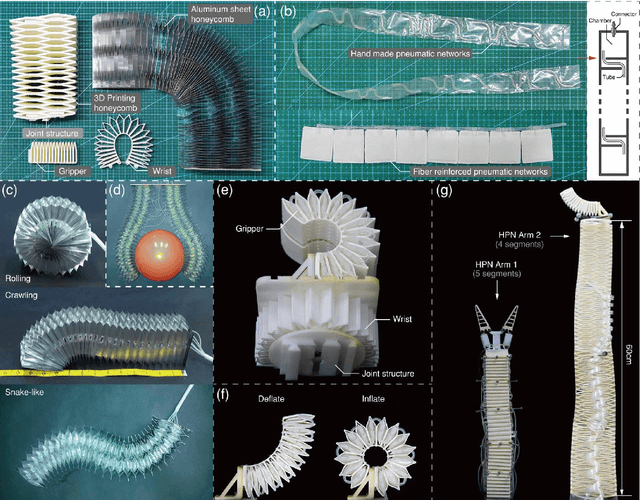

This paper presents the design, control, and applications of a multi-segment soft robotic arm. In order to design a soft arm with large load capacity, several design principles are proposed by analyzing two kinds of buckling issues, under which we present a novel structure named Honeycomb Pneumatic Networks (HPN). Parameter optimization method, based on finite element method (FEM), is proposed to optimize HPN Arm design parameters. Through a quick fabrication process, several prototypes with different performance are made, one of which can achieve the transverse load capacity of 3 kg under 3 bar pressure. Next, considering different internal and external conditions, we develop three controllers according to different model precision. Specifically, based on accurate model, an open-loop controller is realized by combining piece-wise constant curvature (PCC) modeling method and machine learning method. Based on inaccurate model, a feedback controller, using estimated Jacobian, is realized in 3D space. A model-free controller, using reinforcement learning to learn a control policy rather than a model, is realized in 2D plane, with minimal training data. Then, these three control methods are compared on a same experiment platform to explore the applicability of different methods under different conditions. Lastly, we figure out that soft arm can greatly simplify the perception, planning, and control of interaction tasks through its compliance, which is its main advantage over the rigid arm. Through plentiful experiments in three interaction application scenarios, human-robot interaction, free space interaction task, and confined space interaction task, we demonstrate the potential application prospect of the soft arm.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge