Design and Fabrication of a Fiber Bragg Grating Shape Sensor for Shape Reconstruction of a Continuum Manipulator

Paper and Code

Mar 07, 2023

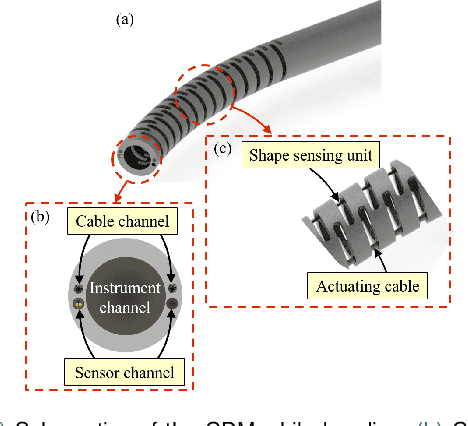

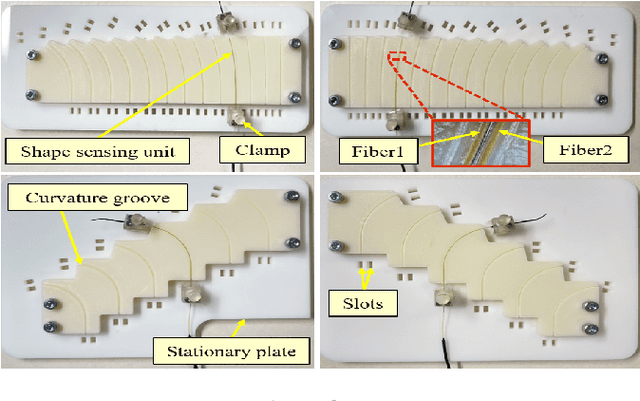

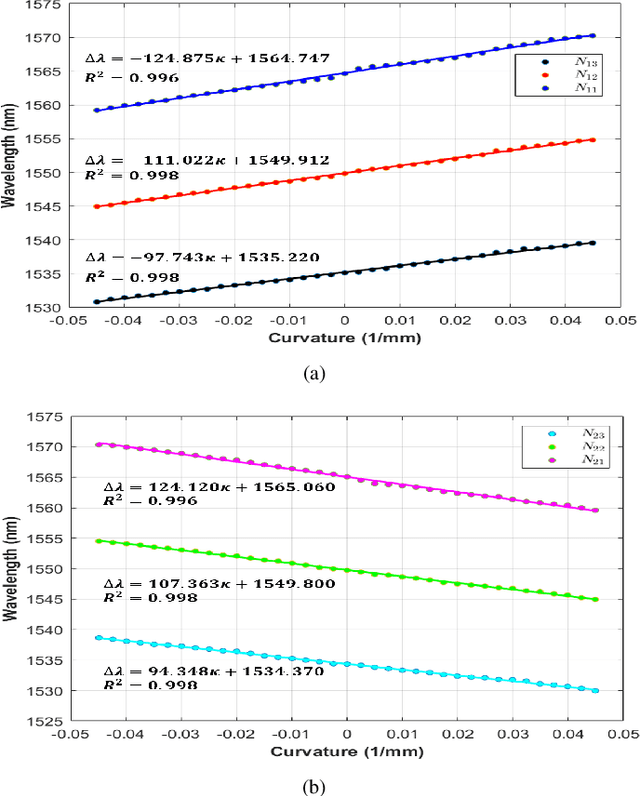

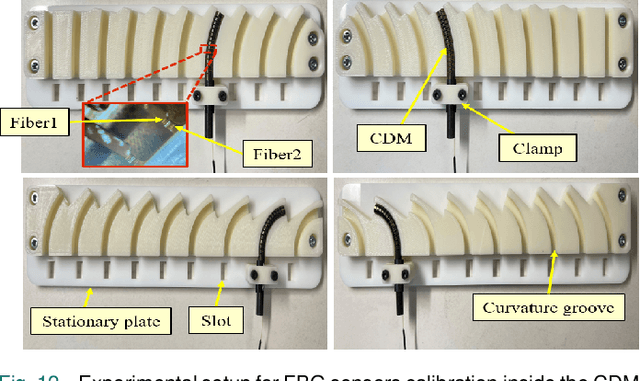

Continuum dexterous manipulators (CDMs) are suitable for performing tasks in a constrained environment due to their high dexterity and maneuverability. Despite the inherent advantages of CDMs in minimally invasive surgery, real-time control of CDMs' shape during non-constant curvature bending is still challenging. This study presents a novel approach for the design and fabrication of a large deflection fiber Bragg grating (FBG) shape sensor embedded within the lumens inside the walls of a CDM with a large instrument channel. The shape sensor consisted of two fibers, each with three FBG nodes. A shape-sensing model was introduced to reconstruct the centerline of the CDM based on FBG wavelengths. Different experiments, including shape sensor tests and CDM shape reconstruction tests, were conducted to assess the overall accuracy of the shape sensing. The FBG sensor evaluation results revealed the linear curvature-wavelength relationship with the large curvature detection of 0.045 mm at a 90 degrees bending angle and a sensitivity of up to 5.50 nm/mm in each bending direction. The CDM's shape reconstruction experiments in a free environment demonstrated the shape tracking accuracy of 0.216+-0.126 mm for positive/negative deflections. Also, the CDM shape reconstruction error for three cases of bending with obstacles were observed to be 0.436+-0.370 mm for the proximal case, 0.485+-0.418 mm for the middle case, and 0.312+-0.261 mm for the distal case. This study indicates the adequate performance of the FBG sensor and the effectiveness of the model for tracking the shape of the large-deflection CDM with nonconstant-curvature bending for minimally-invasive orthopaedic applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge