Deep Learning-based Pipeline for Module Power Prediction from EL Measurements

Paper and Code

Sep 30, 2020

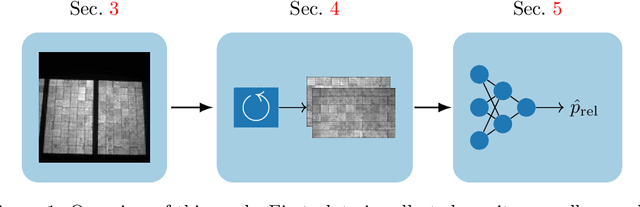

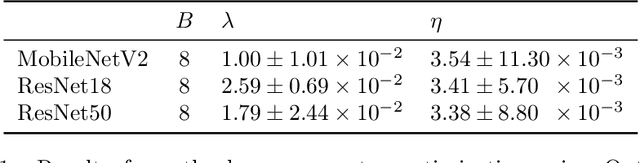

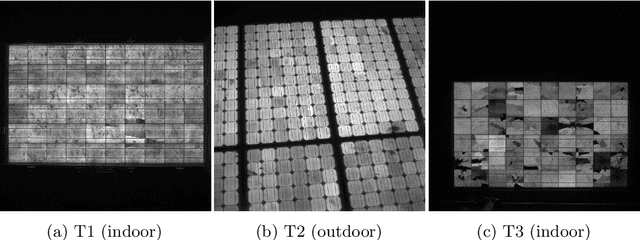

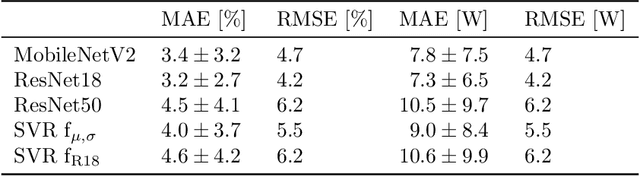

Automated inspection plays an important role in monitoring large-scale photovoltaic power plants. Commonly, electroluminescense measurements are used to identify various types of defects on solar modules but have not been used to determine the power of a module. However, knowledge of the power at maximum power point is important as well, since drops in the power of a single module can affect the performance of an entire string. By now, this is commonly determined by measurements that require to discontact or even dismount the module, rendering a regular inspection of individual modules infeasible. In this work, we bridge the gap between electroluminescense measurements and the power determination of a module. We compile a large dataset of 719 electroluminescense measurementsof modules at various stages of degradation, especially cell cracks and fractures, and the corresponding power at maximum power point. Here,we focus on inactive regions and cracks as the predominant type of defect. We set up a baseline regression model to predict the power from electroluminescense measurements with a mean absolute error of 9.0+/-3.7W (4.0+/-8.4%). Then, we show that deep-learning can be used to train a model that performs significantly better (7.3+/-2.7W or 3.2+/-6.5%). With this work, we aim to open a new research topic. Therefore, we publicly release the dataset, the code and trained models to empower other researchers to compare against our results. Finally, we present a thorough evaluation of certain boundary conditions like the dataset size and an automated preprocessing pipeline for on-site measurements showing multiple modules at once.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge