Cloth Funnels: Canonicalized-Alignment for Multi-Purpose Garment Manipulation

Paper and Code

Oct 17, 2022

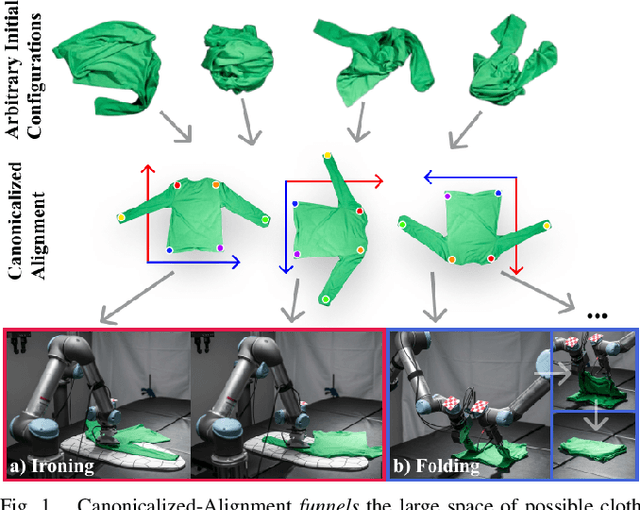

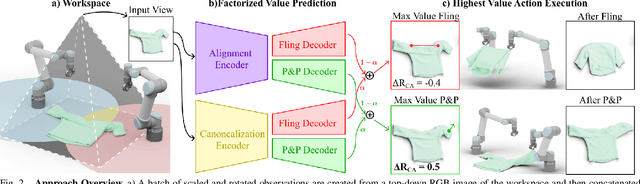

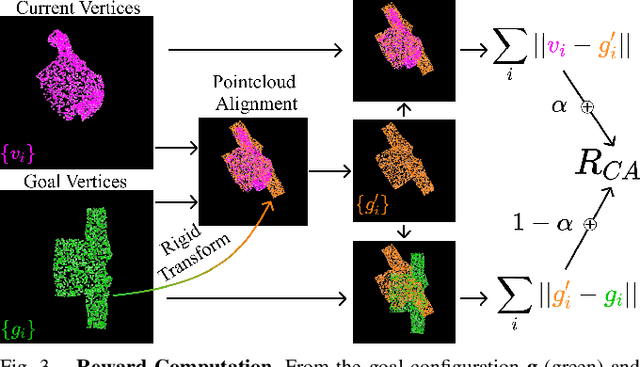

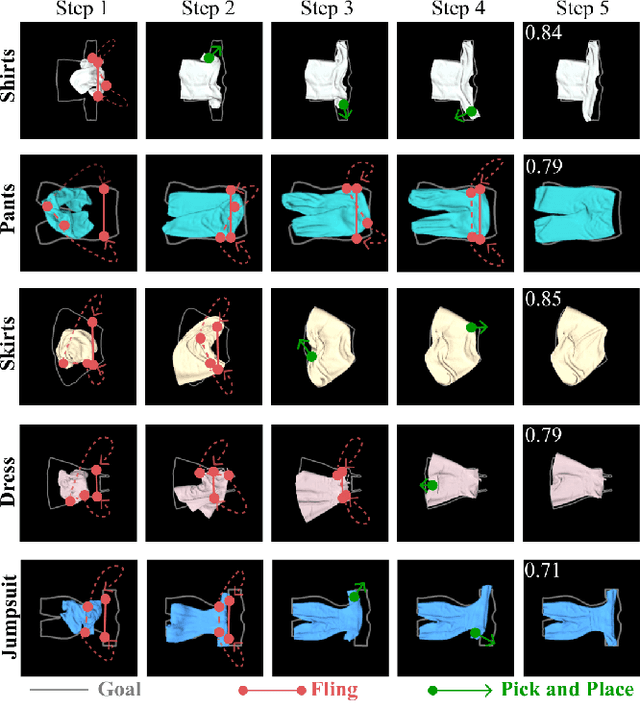

Automating garment manipulation is challenging due to extremely high variability in object configurations. To reduce this intrinsic variation, we introduce the task of "canonicalized-alignment" that simplifies downstream applications by reducing the possible garment configurations. This task can be considered as "cloth state funnel" that manipulates arbitrarily configured clothing items into a predefined deformable configuration (i.e. canonicalization) at an appropriate rigid pose (i.e. alignment). In the end, the cloth items will result in a compact set of structured and highly visible configurations - which are desirable for downstream manipulation skills. To enable this task, we propose a novel canonicalized-alignment objective that effectively guides learning to avoid adverse local minima during learning. Using this objective, we learn a multi-arm, multi-primitive policy that strategically chooses between dynamic flings and quasi-static pick and place actions to achieve efficient canonicalized-alignment. We evaluate this approach on a real-world ironing and folding system that relies on this learned policy as the common first step. Empirically, we demonstrate that our task-agnostic canonicalized-alignment can enable even simple manually-designed policies to work well where they were previously inadequate, thus bridging the gap between automated non-deformable manufacturing and deformable manipulation. Code and qualitative visualizations are available at https://clothfunnels.cs.columbia.edu/. Video can be found at https://www.youtube.com/watch?v=TkUn0b7mbj0.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge