Zhian Kuang

Safe Online Gain Optimization for Variable Impedance Control

Nov 01, 2021

Abstract:Smooth behaviors are preferable for many contact-rich manipulation tasks. Impedance control arises as an effective way to regulate robot movements by mimicking a mass-spring-damping system. Consequently, the robot behavior can be determined by the impedance gains. However, tuning the impedance gains for different tasks is tricky, especially for unstructured environments. Moreover, online adapting the optimal gains to meet the time-varying performance index is even more challenging. In this paper, we present Safe Online Gain Optimization for Variable Impedance Control (Safe OnGO-VIC). By reformulating the dynamics of impedance control as a control-affine system, in which the impedance gains are the inputs, we provide a novel perspective to understand variable impedance control. Additionally, we innovatively formulate an optimization problem with online collected force information to obtain the optimal impedance gains in real-time. Safety constraints are also embedded in the proposed framework to avoid unwanted collisions. We experimentally validated the proposed algorithm on three manipulation tasks. Comparison results with a constant gain baseline and an adaptive control method prove that the proposed algorithm is effective and generalizable to different scenarios.

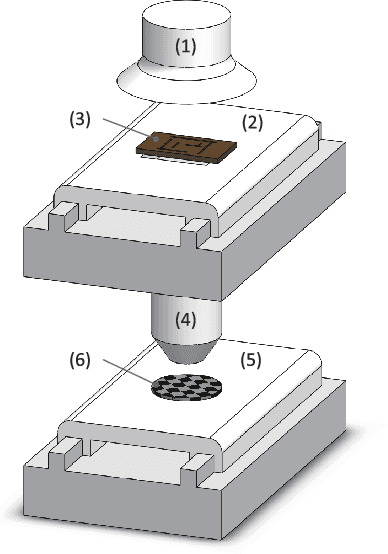

Development of Soft Tactile Sensor for Force Measurement and Position Detection

May 15, 2021

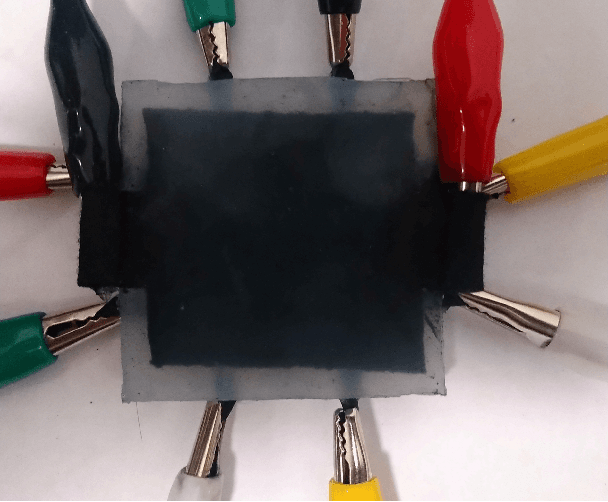

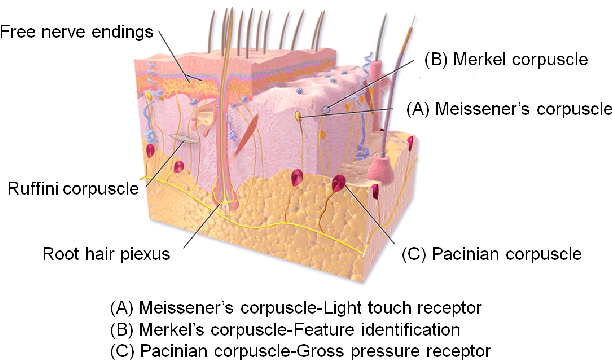

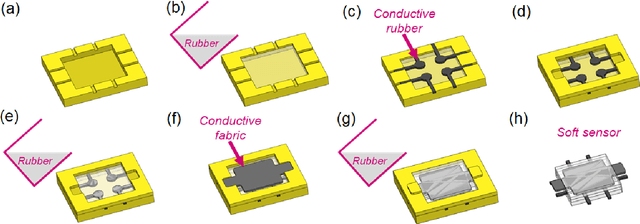

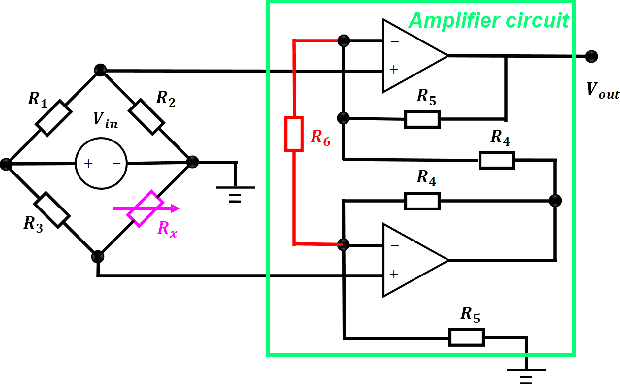

Abstract:As more robots are implemented for contact-rich tasks, tactile sensors are in increasing demand. For many circumstances, the contact is required to be compliant, and soft sensors are in need. This paper introduces a novelly designed soft sensor that can simultaneously estimate the contact force and contact location. Inspired by humans' skin, which contains multi-layers of receptors, the designed tactile sensor has a dual-layer structure. The first layer is made of a conductive fabric that is responsible for sensing the contact force. The second layer is composed of four small conductive rubbers that can detect the contact location. Signals from the two layers are firstly processed by Wheatstone bridges and amplifier circuits so that the measurement noises are eliminated, and the sensitivity is improved. An Arduino chip is used for processing the signal and analyzing the data. The contact force can be obtained by a pre-trained model that maps from the voltage to force, and the contact location is estimated by the voltage signal from the conductive rubbers in the second layer. In addition, filtering methods are applied to eliminate the estimation noise. Finally, experiments are provided to show the accuracy and robustness of the sensor.

Learning Variable Impedance Control via Inverse Reinforcement Learning for Force-Related Tasks

Feb 13, 2021

Abstract:Many manipulation tasks require robots to interact with unknown environments. In such applications, the ability to adapt the impedance according to different task phases and environment constraints is crucial for safety and performance. Although many approaches based on deep reinforcement learning (RL) and learning from demonstration (LfD) have been proposed to obtain variable impedance skills on contact-rich manipulation tasks, these skills are typically task-specific and could be sensitive to changes in task settings. This paper proposes an inverse reinforcement learning (IRL) based approach to recover both the variable impedance policy and reward function from expert demonstrations. We explore different action space of the reward functions to achieve a more general representation of expert variable impedance skills. Experiments on two variable impedance tasks (Peg-in-Hole and Cup-on-Plate) were conducted in both simulations and on a real FANUC LR Mate 200iD/7L industrial robot. The comparison results with behavior cloning and force-based IRL proved that the learned reward function in the gain action space has better transferability than in the force space. Experiment videos are available at https://msc.berkeley.edu/research/impedance-irl.html.

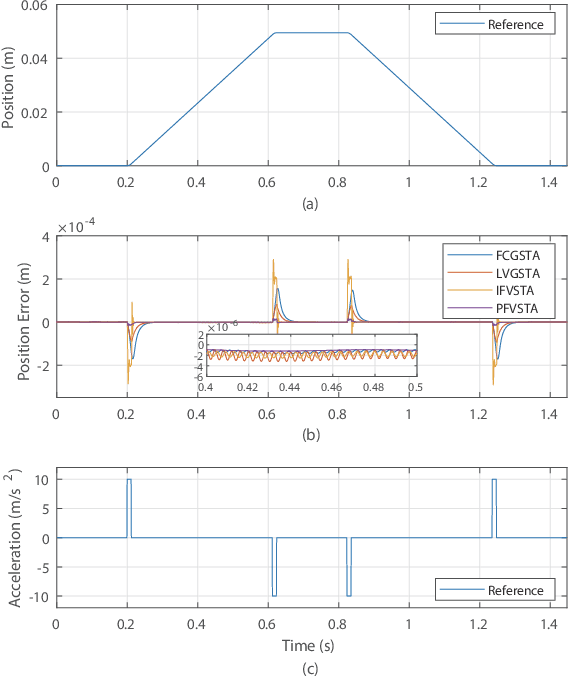

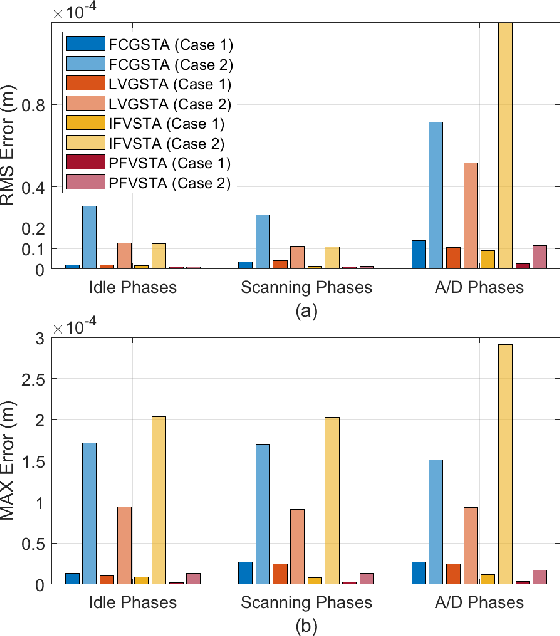

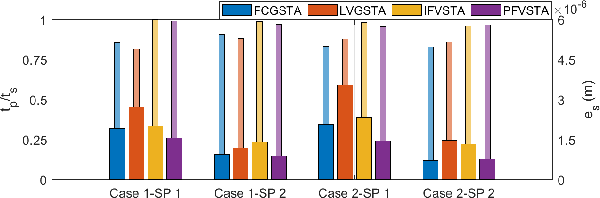

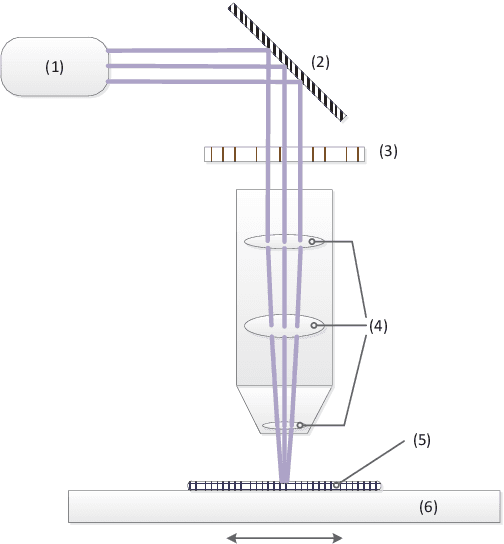

Practical Fractional-Order Variable-Gain Super-Twisting Control with Application to Wafer Stages of Photolithography Systems

Feb 06, 2021

Abstract:In this paper, a practical fractional-order variable-gain super-twisting algorithm (PFVSTA) is proposed to improve the tracking performance of wafer stages for semiconductor manufacturing. Based on the sliding mode control (SMC), the proposed PFVSTA enhances the tracking performance from three aspects: 1) alleviating the chattering phenomenon via super-twisting algorithm and a novel fractional-order sliding surface~(FSS) design, 2) improving the dynamics of states on the sliding surface with fast response and small overshoots via the designed novel FSS and 3) compensating for disturbances via variable-gain control law. Based on practical conditions, this paper analyzes the stability of the controller and illustrates the theoretical principle to compensate for the uncertainties caused by accelerations. Moreover, numerical simulations prove the effectiveness of the proposed sliding surface and control scheme, and they are in agreement with the theoretical analysis. Finally, practice-based comparative experiments are conducted. The results show that the proposed PFVSTA can achieve much better tracking performance than the conventional methods from various perspectives.

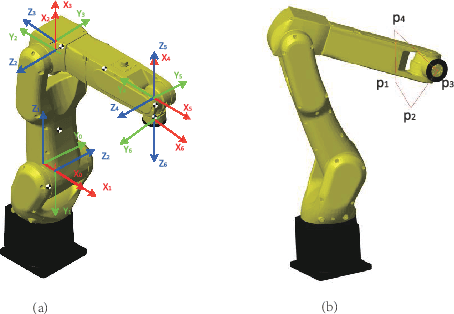

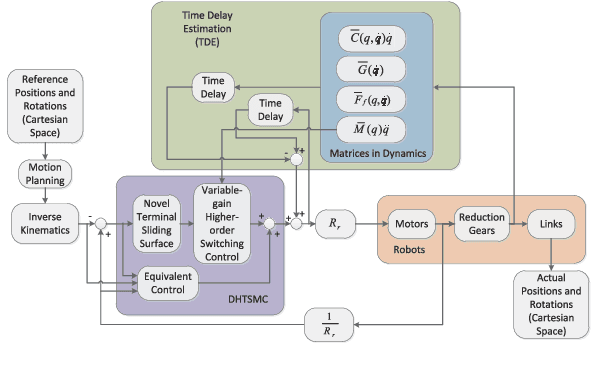

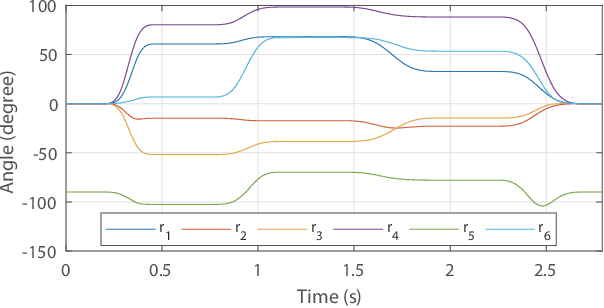

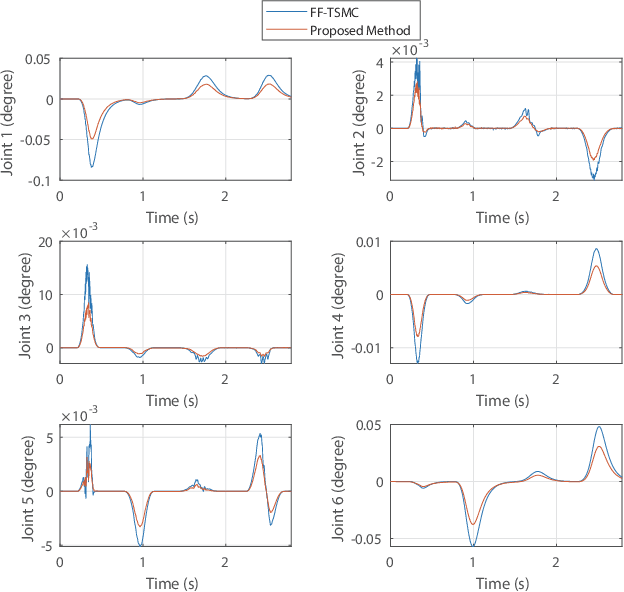

Feedback-based Digital Higher-order Terminal Sliding Mode for 6-DOF Industrial Manipulators

Feb 06, 2021

Abstract:The precise motion control of a multi-degree of freedom~(DOF) robot manipulator is always challenging due to its nonlinear dynamics, disturbances, and uncertainties. Because most manipulators are controlled by digital signals, a novel higher-order sliding mode controller in the discrete-time form with time delay estimation is proposed in this paper. The dynamic model of the manipulator used in the design allows proper handling of nonlinearities, uncertainties and disturbances involved in the problem. Specifically, parametric uncertainties and disturbances are handled by the time delay estimation and the nonlinearity of the manipulator is addressed by the feedback structure of the controller. The combination of terminal sliding mode surface and higher-order control scheme in the controller guarantees a fast response with a small chattering amplitude. Moreover, the controller is designed with a modified sliding mode surface and variable-gain structure, so that the performance of the controller is further enhanced. We also analyze the condition to guarantee the stability of the closed-loop system in this paper. Finally, the simulation and experimental results prove that the proposed control scheme has a precise performance in a robot manipulator system.

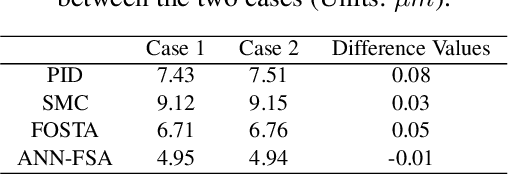

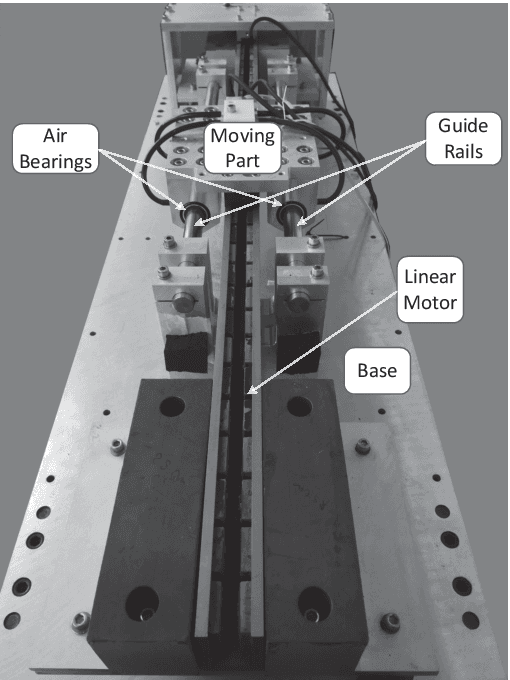

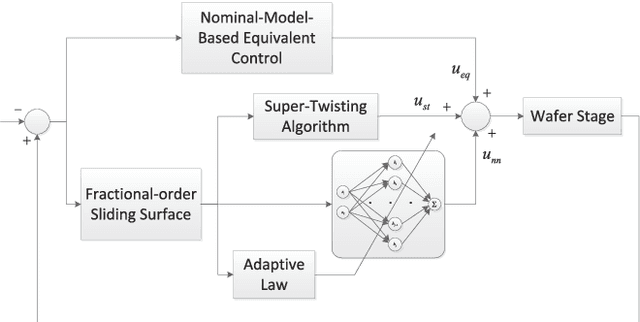

Precise Motion Control of Wafer Stages via Adaptive Neural Network and Fractional-Order Super-Twisting Algorithm

Jan 31, 2021

Abstract:To obtain precise motion control of wafer stages, an adaptive neural network and fractional-order super-twisting control strategy is proposed. Based on sliding mode control (SMC), the proposed controller aims to address two challenges in SMC: 1) reducing the chattering phenomenon, and 2) attenuating the influence of model uncertainties and disturbances. For the first challenge, a fractional-order terminal sliding mode surface and a super-twisting algorithm are integrated into the SMC design. To attenuate uncertainties and disturbances, an add-on control structure based on the radial basis function (RBF) neural network is introduced. Stability analysis of the closed-loop control system is provided. Finally, experiments on a wafer stage testbed system are conducted, which proves that the proposed controller can robustly improve the tracking performance in the presence of uncertainties and disturbances compared to conventional and previous controllers.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge