Zhenishbek Zhakypov

Hoxels: Fully 3-D Printed Soft Multi-Modal & Multi-Contact Haptic Voxel Displays for Enriched Tactile Information Transfer

Sep 12, 2022

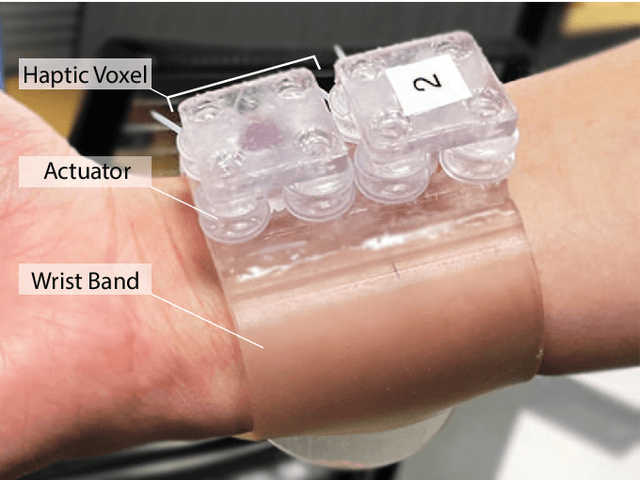

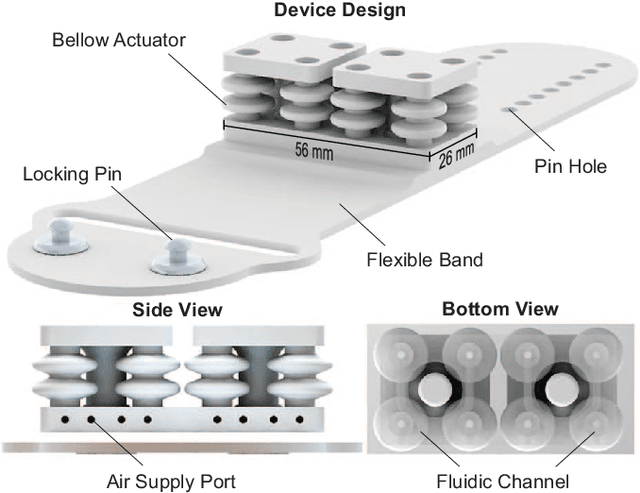

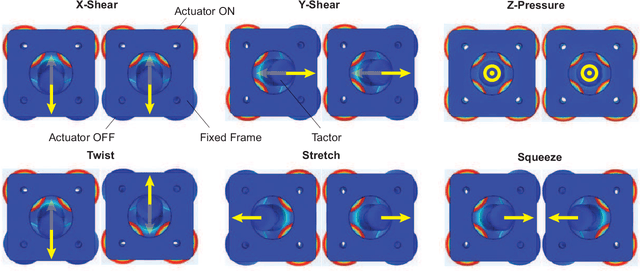

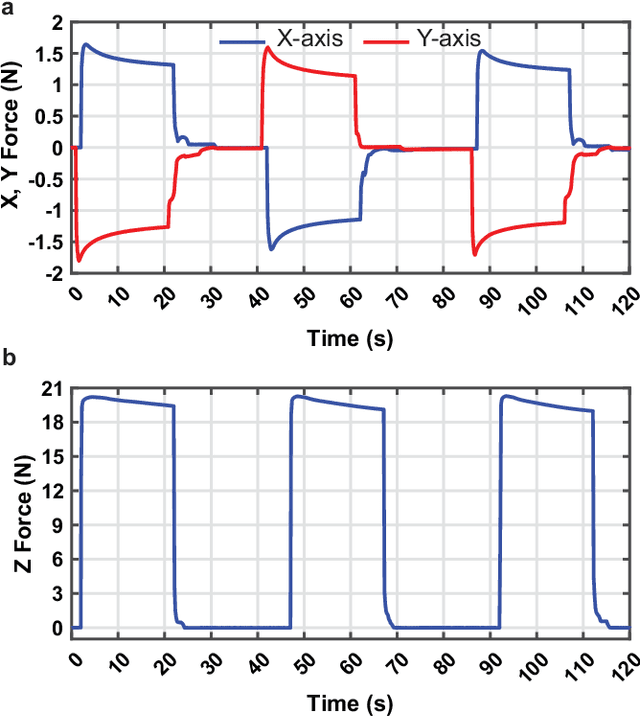

Abstract:Wrist-worn haptic interfaces can deliver a wide range of tactile cues for communication of information and interaction with virtual objects. Unlike fingertips, the wrist and forearm provide a considerably large area of skin that allows the placement of multiple haptic actuators as a display for enriching tactile information transfer with minimal encumbrance. Existing multi-degree-of-freedom (DoF) wrist-worn devices employ traditional rigid robotic mechanisms and electric motors that limit their versatility, miniaturization, distribution, and assembly. Alternative solutions based on soft elastomeric actuator arrays constitute only 1-DoF haptic pixels. Higher-DoF prototypes produce a single interaction point and require complex manual assembly processes, such as molding and gluing several parts. These approaches limit the construction of high-DoF compact haptic displays, repeatability, and customizability. Here we present a novel, fully 3D-printed, soft, wearable haptic display for increasing tactile information transfer on the wrist and forearm with 3-DoF haptic voxels, called hoxels. Our initial prototype comprises two hoxels that provide skin shear, pressure, twist, stretch, squeeze, and other arbitrary stimuli. Each hoxel generates force up to 1.6 N in the x and y-axes and up to 20 N in the z-axis. Our method enables the rapid fabrication of versatile and forceful haptic displays.

FingerPrint: A 3-D Printed Soft Monolithic 4-Degree-of-Freedom Fingertip Haptic Device with Embedded Actuation

Mar 27, 2022

Abstract:Wearable fingertip haptic interfaces provide tactile stimuli on the fingerpads by applying skin pressure, linear and rotational shear, and vibration. Designing and fabricating a compact, multi-degree-of-freedom, and forceful fingertip haptic interface is challenging due to trade-offs among miniaturization, multifunctionality, and manufacturability. Downsizing electromagnetic actuators that produce high torques is infeasible, and integrating multiple actuators, links, joints, and transmission elements increases device size and weight. 3-D printing enables rapid manufacturing of complex devices with minimal assembly in large batches. However, it requires a careful arrangement of material properties, geometry, scale, and printer capabilities. Here we present a fully 3-D printed, soft, monolithic fingertip haptic device based on an origami pattern known as the "waterbomb" base that embeds foldable vacuum actuation and produces 4-DoF of motion on the fingerpad with tunable haptic forces (up to 1.3 N shear and 7 N normal) and torque (up to 25 N-mm). Including the thimble mounting, the compact device is 40 mm long and 20 mm wide. This demonstrates the efficacy of origami design and soft material 3D printing for designing and rapidly fabricating miniature yet complex wearable mechanisms with force output appropriate for haptic interaction.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge