Yuanhong Zeng

Risk-Aware Reinforcement Learning with Bandit-Based Adaptation for Quadrupedal Locomotion

Oct 16, 2025Abstract:In this work, we study risk-aware reinforcement learning for quadrupedal locomotion. Our approach trains a family of risk-conditioned policies using a Conditional Value-at-Risk (CVaR) constrained policy optimization technique that provides improved stability and sample efficiency. At deployment, we adaptively select the best performing policy from the family of policies using a multi-armed bandit framework that uses only observed episodic returns, without any privileged environment information, and adapts to unknown conditions on the fly. Hence, we train quadrupedal locomotion policies at various levels of robustness using CVaR and adaptively select the desired level of robustness online to ensure performance in unknown environments. We evaluate our method in simulation across eight unseen settings (by changing dynamics, contacts, sensing noise, and terrain) and on a Unitree Go2 robot in previously unseen terrains. Our risk-aware policy attains nearly twice the mean and tail performance in unseen environments compared to other baselines and our bandit-based adaptation selects the best-performing risk-aware policy in unknown terrain within two minutes of operation.

Triple Regression for Camera Agnostic Sim2Real Robot Grasping and Manipulation Tasks

Sep 16, 2023

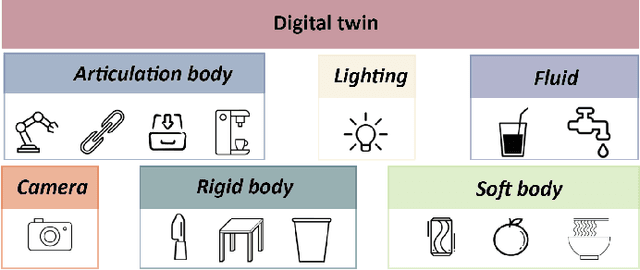

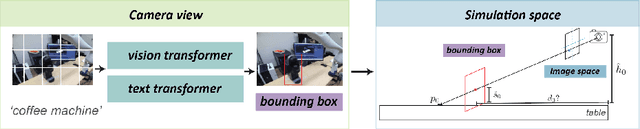

Abstract:Sim2Real (Simulation to Reality) techniques have gained prominence in robotic manipulation and motion planning due to their ability to enhance success rates by enabling agents to test and evaluate various policies and trajectories. In this paper, we investigate the advantages of integrating Sim2Real into robotic frameworks. We introduce the Triple Regression Sim2Real framework, which constructs a real-time digital twin. This twin serves as a replica of reality to simulate and evaluate multiple plans before their execution in real-world scenarios. Our triple regression approach addresses the reality gap by: (1) mitigating projection errors between real and simulated camera perspectives through the first two regression models, and (2) detecting discrepancies in robot control using the third regression model. Experiments on 6-DoF grasp and manipulation tasks (where the gripper can approach from any direction) highlight the effectiveness of our framework. Remarkably, with only RGB input images, our method achieves state-of-the-art success rates. This research advances efficient robot training methods and sets the stage for rapid advancements in robotics and automation.

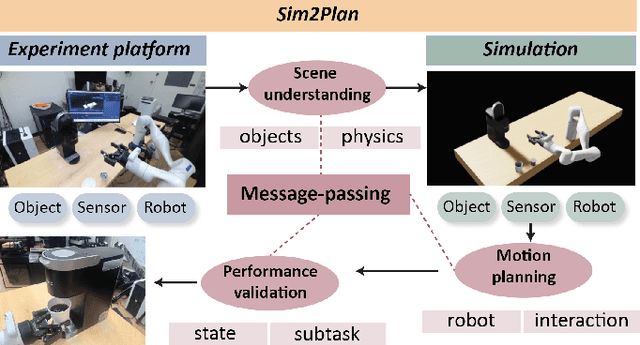

Sim2Plan: Robot Motion Planning via Message Passing between Simulation and Reality

Jul 15, 2023

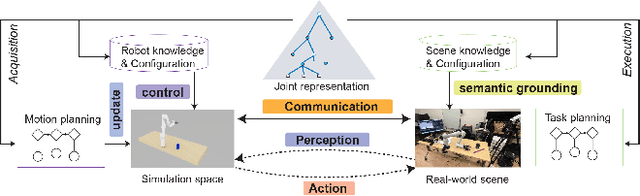

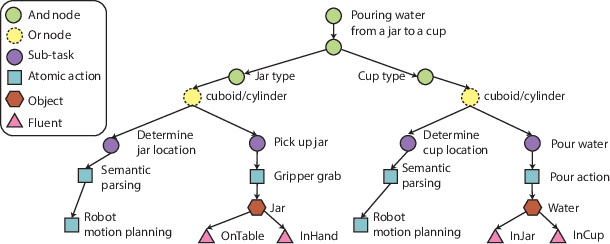

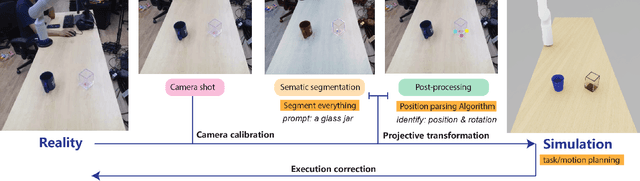

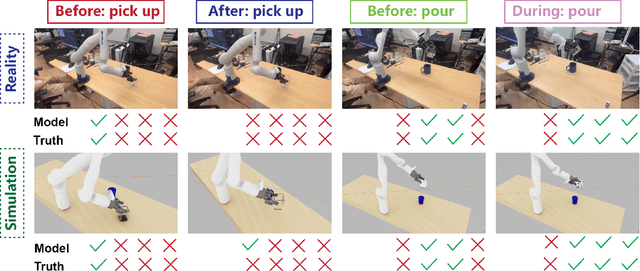

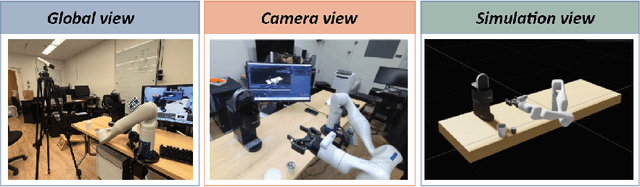

Abstract:Simulation-to-real is the task of training and developing machine learning models and deploying them in real settings with minimal additional training. This approach is becoming increasingly popular in fields such as robotics. However, there is often a gap between the simulated environment and the real world, and machine learning models trained in simulation may not perform as well in the real world. We propose a framework that utilizes a message-passing pipeline to minimize the information gap between simulation and reality. The message-passing pipeline is comprised of three modules: scene understanding, robot planning, and performance validation. First, the scene understanding module aims to match the scene layout between the real environment set-up and its digital twin. Then, the robot planning module solves a robotic task through trial and error in the simulation. Finally, the performance validation module varies the planning results by constantly checking the status difference of the robot and object status between the real set-up and the simulation. In the experiment, we perform a case study that requires a robot to make a cup of coffee. Results show that the robot is able to complete the task under our framework successfully. The robot follows the steps programmed into its system and utilizes its actuators to interact with the coffee machine and other tools required for the task. The results of this case study demonstrate the potential benefits of our method that drive robots for tasks that require precision and efficiency. Further research in this area could lead to the development of even more versatile and adaptable robots, opening up new possibilities for automation in various industries.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge