Thomas Hogan

Data-Driven Aerospace Engineering: Reframing the Industry with Machine Learning

Aug 24, 2020

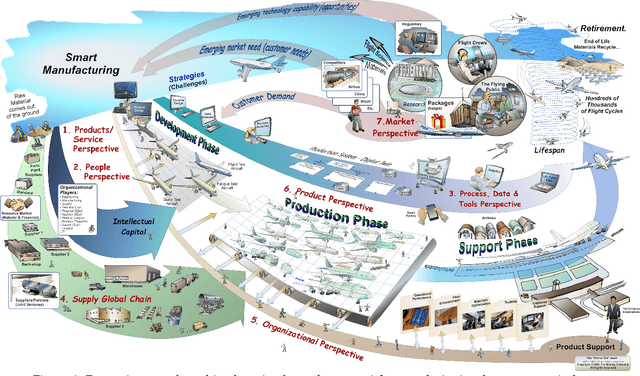

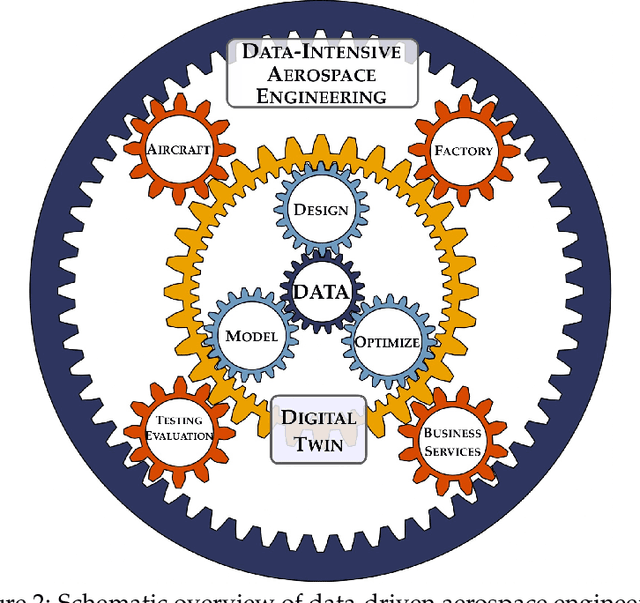

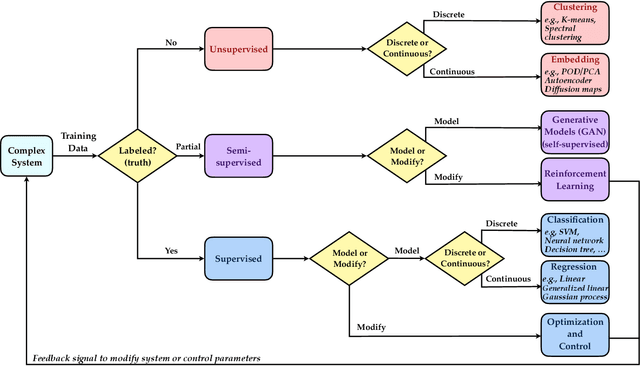

Abstract:Data science, and machine learning in particular, is rapidly transforming the scientific and industrial landscapes. The aerospace industry is poised to capitalize on big data and machine learning, which excels at solving the types of multi-objective, constrained optimization problems that arise in aircraft design and manufacturing. Indeed, emerging methods in machine learning may be thought of as data-driven optimization techniques that are ideal for high-dimensional, non-convex, and constrained, multi-objective optimization problems, and that improve with increasing volumes of data. In this review, we will explore the opportunities and challenges of integrating data-driven science and engineering into the aerospace industry. Importantly, we will focus on the critical need for interpretable, generalizeable, explainable, and certifiable machine learning techniques for safety-critical applications. This review will include a retrospective, an assessment of the current state-of-the-art, and a roadmap looking forward. Recent algorithmic and technological trends will be explored in the context of critical challenges in aerospace design, manufacturing, verification, validation, and services. In addition, we will explore this landscape through several case studies in the aerospace industry. This document is the result of close collaboration between UW and Boeing to summarize past efforts and outline future opportunities.

Predicting shim gaps in aircraft assembly with machine learning and sparse sensing

Nov 24, 2017

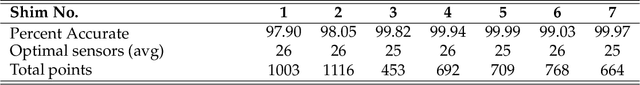

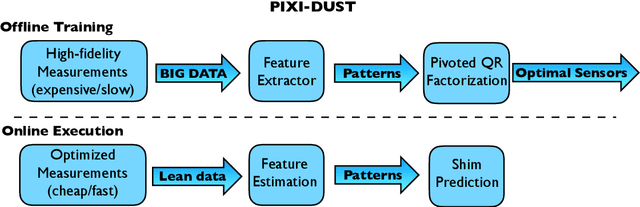

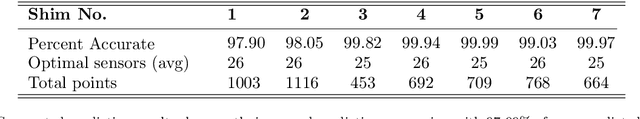

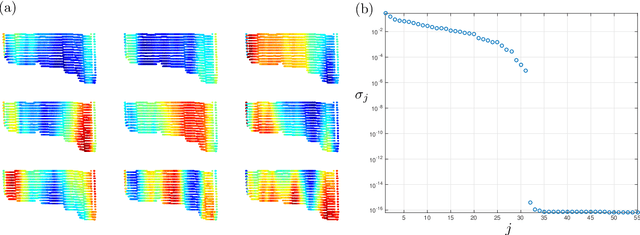

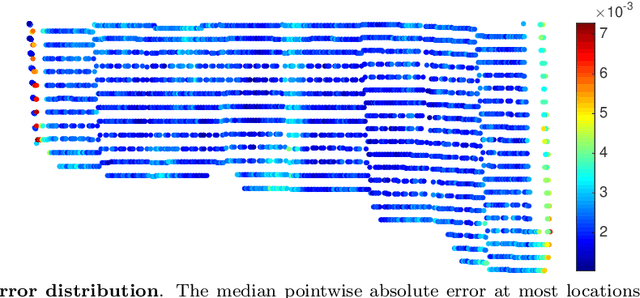

Abstract:A modern aircraft may require on the order of thousands of custom shims to fill gaps between structural components in the airframe that arise due to manufacturing tolerances adding up across large structures. These shims are necessary to eliminate gaps, maintain structural performance, and minimize pull-down forces required to bring the aircraft into engineering nominal configuration for peak aerodynamic efficiency. Gap filling is a time-consuming process, involving either expensive by-hand inspection or computations on vast quantities of measurement data from increasingly sophisticated metrology equipment. Either case amounts to significant delays in production, with much of the time spent in the critical path of aircraft assembly. This work presents an alternative strategy for predictive shimming, based on machine learning and sparse sensing to first learn gap distributions from historical data, and then design optimized sparse sensing strategies to streamline data collection and processing. This new approach is based on the assumption that patterns exist in shim distributions across aircraft, which may be mined and used to reduce the burden of data collection and processing in future aircraft. Specifically, robust principal component analysis is used to extract low-dimensional patterns in the gap measurements while rejecting outliers. Next, optimized sparse sensors are obtained that are most informative about the dimensions of a new aircraft in these low-dimensional principal components. We demonstrate the success of the proposed approach, called PIXel Identification Despite Uncertainty in Sensor Technology (PIXI-DUST), on historical production data from 54 representative Boeing commercial aircraft. Our algorithm successfully predicts $99\%$ of shim gaps within the desired measurement tolerance using $3\%$ of the laser scan points typically required; all results are cross-validated.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge