Thomas Gries

Demonstrating Data-to-Knowledge Pipelines for Connecting Production Sites in the World Wide Lab

Dec 16, 2024Abstract:The digital transformation of production requires new methods of data integration and storage, as well as decision making and support systems that work vertically and horizontally throughout the development, production, and use cycle. In this paper, we propose Data-to-Knowledge (and Knowledge-to-Data) pipelines for production as a universal concept building on a network of Digital Shadows (a concept augmenting Digital Twins). We show a proof of concept that builds on and bridges existing infrastructure to 1) capture and semantically annotates trajectory data from multiple similar but independent robots in different organisations and use cases in a data lakehouse and 2) an independent process that dynamically queries matching data for training an inverse dynamic foundation model for robotic control. The article discusses the challenges and benefits of this approach and how Data-to-Knowledge pipelines contribute efficiency gains and industrial scalability in a World Wide Lab as a research outlook.

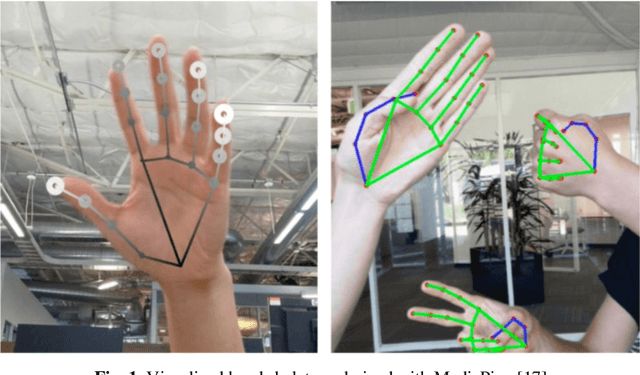

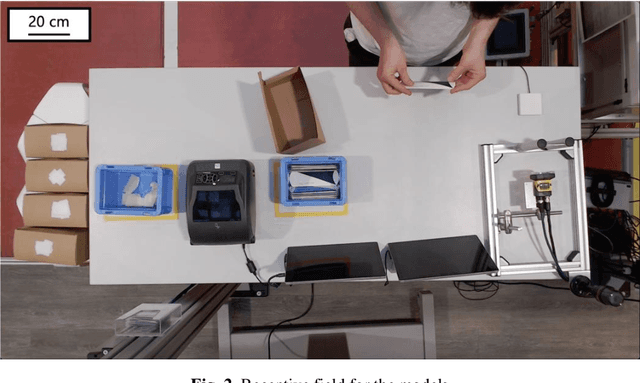

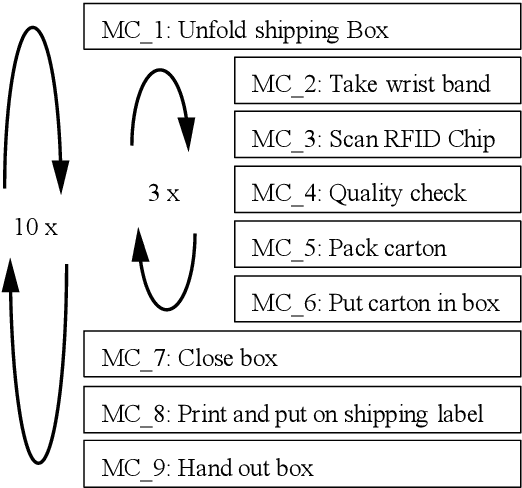

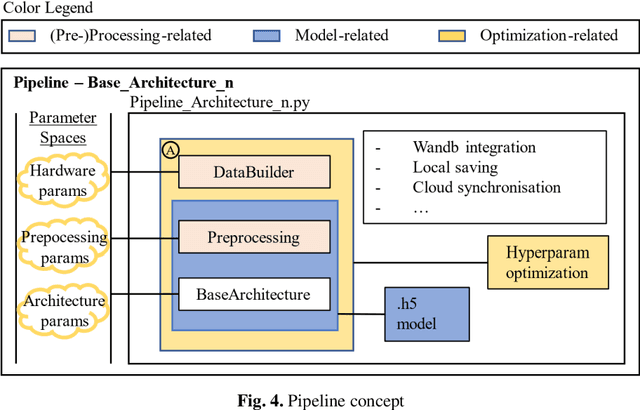

Proving the Potential of Skeleton Based Action Recognition to Automate the Analysis of Manual Processes

Oct 12, 2023

Abstract:In manufacturing sectors such as textiles and electronics, manual processes are a fundamental part of production. The analysis and monitoring of the processes is necessary for efficient production design. Traditional methods for analyzing manual processes are complex, expensive, and inflexible. Compared to established approaches such as Methods-Time-Measurement (MTM), machine learning (ML) methods promise: Higher flexibility, self-sufficient & permanent use, lower costs. In this work, based on a video stream, the current motion class in a manual assembly process is detected. With information on the current motion, Key-Performance-Indicators (KPIs) can be derived easily. A skeleton-based action recognition approach is taken, as this field recently shows major success in machine vision tasks. For skeleton-based action recognition in manual assembly, no sufficient pre-work could be found. Therefore, a ML pipeline is developed, to enable extensive research on different (pre-) processing methods and neural nets. Suitable well generalizing approaches are found, proving the potential of ML to enhance analyzation of manual processes. Models detect the current motion, performed by an operator in manual assembly, but the results can be transferred to all kinds of manual processes.

Scalable Concept Extraction in Industry 4.0

Jun 06, 2023Abstract:The industry 4.0 is leveraging digital technologies and machine learning techniques to connect and optimize manufacturing processes. Central to this idea is the ability to transform raw data into human understandable knowledge for reliable data-driven decision-making. Convolutional Neural Networks (CNNs) have been instrumental in processing image data, yet, their ``black box'' nature complicates the understanding of their prediction process. In this context, recent advances in the field of eXplainable Artificial Intelligence (XAI) have proposed the extraction and localization of concepts, or which visual cues intervene on the prediction process of CNNs. This paper tackles the application of concept extraction (CE) methods to industry 4.0 scenarios. To this end, we modify a recently developed technique, ``Extracting Concepts with Local Aggregated Descriptors'' (ECLAD), improving its scalability. Specifically, we propose a novel procedure for calculating concept importance, utilizing a wrapper function designed for CNNs. This process is aimed at decreasing the number of times each image needs to be evaluated. Subsequently, we demonstrate the potential of CE methods, by applying them in three industrial use cases. We selected three representative use cases in the context of quality control for material design (tailored textiles), manufacturing (carbon fiber reinforcement), and maintenance (photovoltaic module inspection). In these examples, CE was able to successfully extract and locate concepts directly related to each task. This is, the visual cues related to each concept, coincided with what human experts would use to perform the task themselves, even when the visual cues were entangled between multiple classes. Through empirical results, we show that CE can be applied for understanding CNNs in an industrial context, giving useful insights that can relate to domain knowledge.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge