Syed Bahauddin Alam

Agentic Physical AI toward a Domain-Specific Foundation Model for Nuclear Reactor Control

Dec 29, 2025Abstract:The prevailing paradigm in AI for physical systems, scaling general-purpose foundation models toward universal multimodal reasoning, confronts a fundamental barrier at the control interface. Recent benchmarks show that even frontier vision-language models achieve only 50-53% accuracy on basic quantitative physics tasks, behaving as approximate guessers that preserve semantic plausibility while violating physical constraints. This input unfaithfulness is not a scaling deficiency but a structural limitation. Perception-centric architectures optimize parameter-space imitation, whereas safety-critical control demands outcome-space guarantees over executed actions. Here, we present a fundamentally different pathway toward domain-specific foundation models by introducing compact language models operating as Agentic Physical AI, in which policy optimization is driven by physics-based validation rather than perceptual inference. We train a 360-million-parameter model on synthetic reactor control scenarios, scaling the dataset from 10^3 to 10^5 examples. This induces a sharp phase transition absent in general-purpose models. Small-scale systems exhibit high-variance imitation with catastrophic tail risk, while large-scale models undergo variance collapse exceeding 500x reduction, stabilizing execution-level behavior. Despite balanced exposure to four actuation families, the model autonomously rejects approximately 70% of the training distribution and concentrates 95% of runtime execution on a single-bank strategy. Learned representations transfer across distinct physics and continuous input modalities without architectural modification.

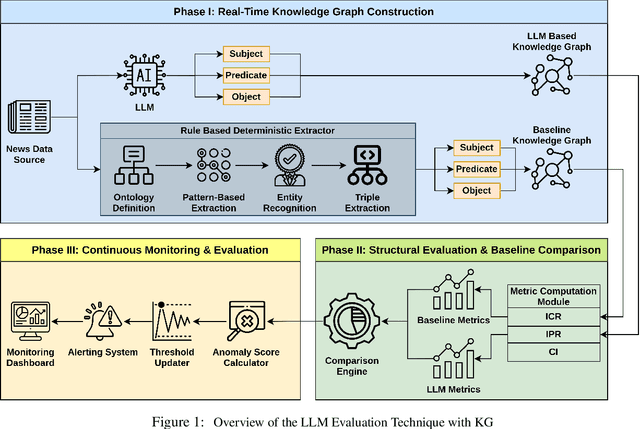

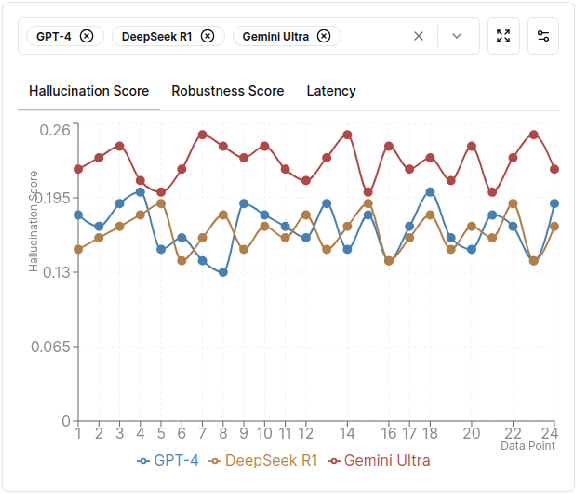

Continuous Monitoring of Large-Scale Generative AI via Deterministic Knowledge Graph Structures

Sep 04, 2025

Abstract:Generative AI (GEN AI) models have revolutionized diverse application domains but present substantial challenges due to reliability concerns, including hallucinations, semantic drift, and inherent biases. These models typically operate as black-boxes, complicating transparent and objective evaluation. Current evaluation methods primarily depend on subjective human assessment, limiting scalability, transparency, and effectiveness. This research proposes a systematic methodology using deterministic and Large Language Model (LLM)-generated Knowledge Graphs (KGs) to continuously monitor and evaluate GEN AI reliability. We construct two parallel KGs: (i) a deterministic KG built using explicit rule-based methods, predefined ontologies, domain-specific dictionaries, and structured entity-relation extraction rules, and (ii) an LLM-generated KG dynamically derived from real-time textual data streams such as live news articles. Utilizing real-time news streams ensures authenticity, mitigates biases from repetitive training, and prevents adaptive LLMs from bypassing predefined benchmarks through feedback memorization. To quantify structural deviations and semantic discrepancies, we employ several established KG metrics, including Instantiated Class Ratio (ICR), Instantiated Property Ratio (IPR), and Class Instantiation (CI). An automated real-time monitoring framework continuously computes deviations between deterministic and LLM-generated KGs. By establishing dynamic anomaly thresholds based on historical structural metric distributions, our method proactively identifies and flags significant deviations, thus promptly detecting semantic anomalies or hallucinations. This structured, metric-driven comparison between deterministic and dynamically generated KGs delivers a robust and scalable evaluation framework.

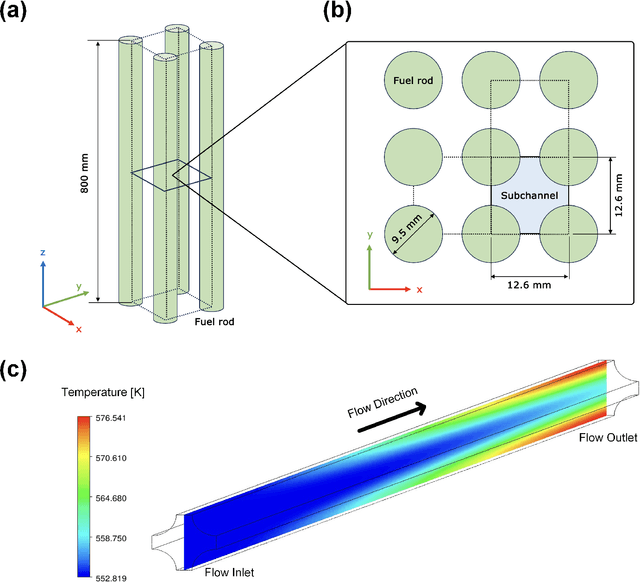

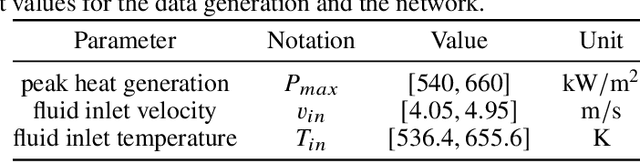

Virtual Sensing to Enable Real-Time Monitoring of Inaccessible Locations \& Unmeasurable Parameters

Nov 28, 2024

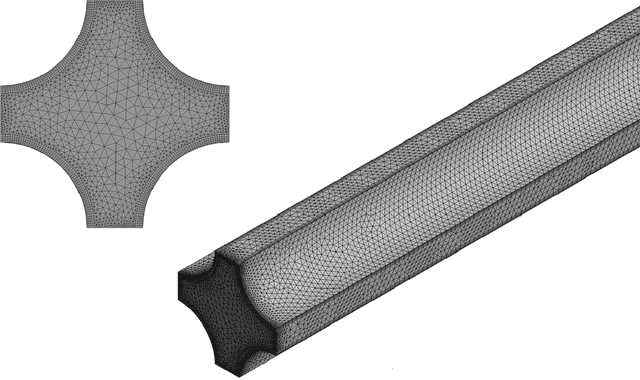

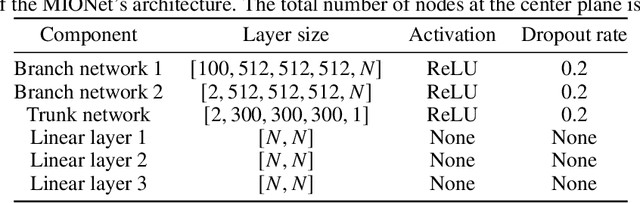

Abstract:Real-time monitoring of critical parameters is essential for energy systems' safe and efficient operation. However, traditional sensors often fail and degrade in harsh environments where physical sensors cannot be placed (inaccessible locations). In addition, there are important parameters that cannot be directly measured by sensors. We need machine learning (ML)-based real-time monitoring in those remote locations to ensure system operations. However, traditional ML models struggle to process continuous sensor profile data to fit model requirements, leading to the loss of spatial relationships. Another challenge for real-time monitoring is ``dataset shift" and the need for frequent retraining under varying conditions, where extensive retraining prohibits real-time inference. To resolve these challenges, this study addressed the limitations of real-time monitoring methods by enabling monitoring in locations where physical sensors are impractical to deploy. Our proposed approach, utilizing Multi-Input Operator Network virtual sensors, leverages deep learning to seamlessly integrate diverse data sources and accurately predict key parameters in real-time without the need for additional physical sensors. The approach's effectiveness is demonstrated through thermal-hydraulic monitoring in a nuclear reactor subchannel, achieving remarkable accuracy.

Virtual Sensing for Real-Time Degradation Monitoring of Nuclear Systems: Leveraging DeepONet for Enhanced Sensing Coverage for Digital Twin-Enabling Technology

Oct 17, 2024

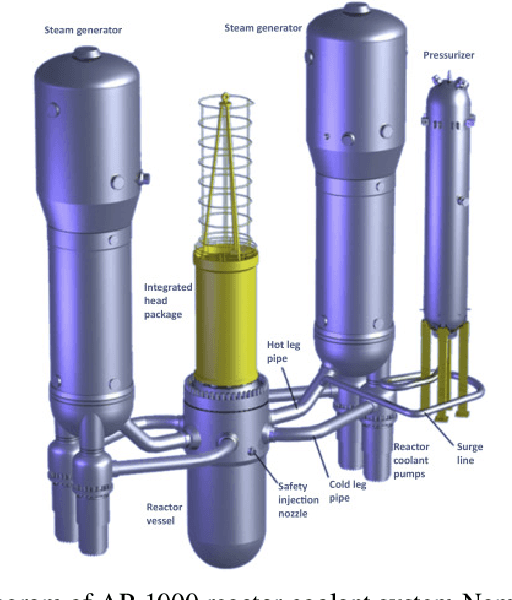

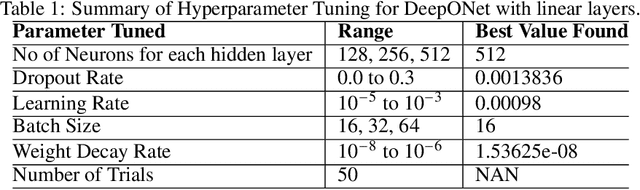

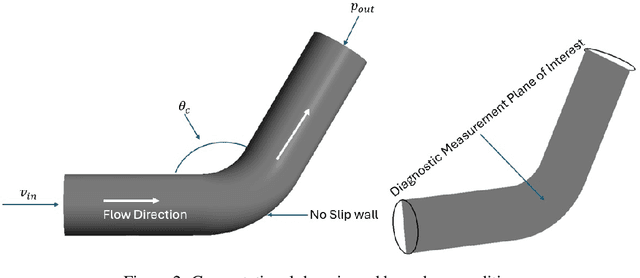

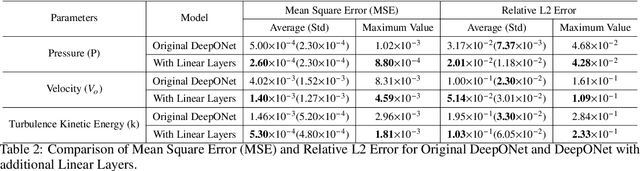

Abstract:Effective real-time monitoring technique is crucial for detecting material degradation and maintaining the structural integrity of nuclear systems to ensure both safety and operational efficiency. Traditional physical sensor systems face limitations such as installation challenges, high costs, and difficulties in measuring critical parameters in hard-to-reach or harsh environments, often resulting in incomplete data coverage. Machine learning-driven virtual sensors offer a promising solution by enhancing physical sensor capabilities to monitor critical degradation indicators like pressure, velocity, and turbulence. However, conventional machine learning models struggle with real-time monitoring due to the high-dimensional nature of reactor data and the need for frequent retraining. This paper explores the use of Deep Operator Networks (DeepONet) within a digital twin (DT) framework to predict key thermal-hydraulic parameters in the hot leg of an AP-1000 Pressurized Water Reactor (PWR). In this study, DeepONet is trained with different operational conditions, which relaxes the requirement of continuous retraining, making it suitable for online and real-time prediction components for DT. Our results show that DeepONet achieves accurate predictions with low mean squared error and relative L2 error and can make predictions on unknown data 160,000 times faster than traditional finite element (FE) simulations. This speed and accuracy make DeepONet a powerful tool for tracking conditions that contribute to material degradation in real-time, enhancing reactor safety and longevity.

Potential of Deep Operator Networks in Digital Twin-enabling Technology for Nuclear System

Aug 15, 2023Abstract:This research introduces the Deep Operator Network (DeepONet) as a robust surrogate modeling method within the context of digital twin (DT) systems for nuclear engineering. With the increasing importance of nuclear energy as a carbon-neutral solution, adopting DT technology has become crucial to enhancing operational efficiencies, safety, and predictive capabilities in nuclear engineering applications. DeepONet exhibits remarkable prediction accuracy, outperforming traditional ML methods. Through extensive benchmarking and evaluation, this study showcases the scalability and computational efficiency of DeepONet in solving a challenging particle transport problem. By taking functions as input data and constructing the operator $G$ from training data, DeepONet can handle diverse and complex scenarios effectively. However, the application of DeepONet also reveals challenges related to optimal sensor placement and model evaluation, critical aspects of real-world implementation. Addressing these challenges will further enhance the method's practicality and reliability. Overall, DeepONet presents a promising and transformative tool for nuclear engineering research and applications. Its accurate prediction and computational efficiency capabilities can revolutionize DT systems, advancing nuclear engineering research. This study marks an important step towards harnessing the power of surrogate modeling techniques in critical engineering domains.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge