Virtual Sensing for Real-Time Degradation Monitoring of Nuclear Systems: Leveraging DeepONet for Enhanced Sensing Coverage for Digital Twin-Enabling Technology

Paper and Code

Oct 17, 2024

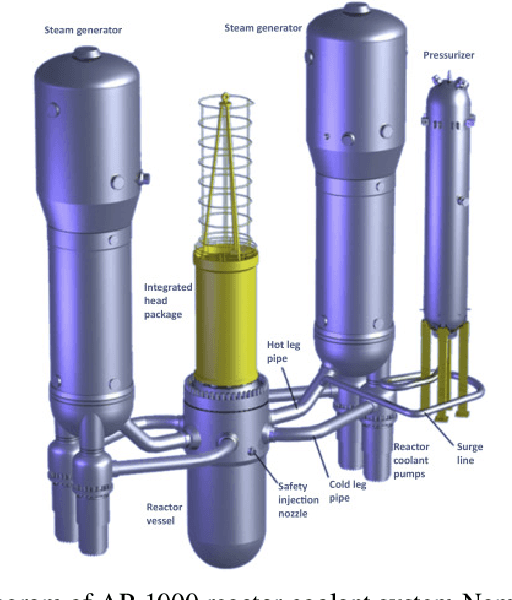

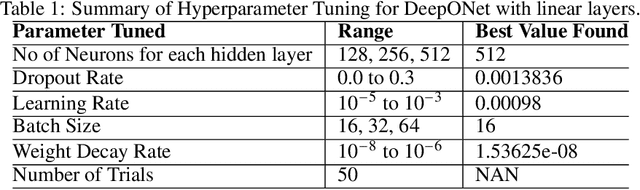

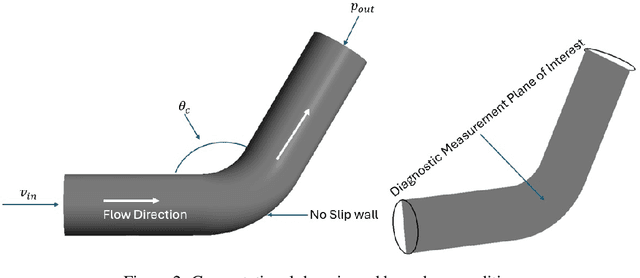

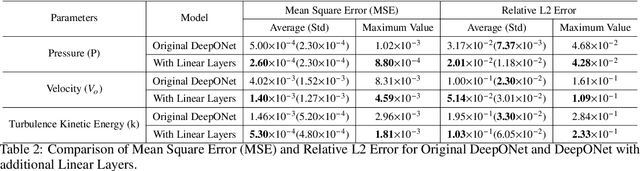

Effective real-time monitoring technique is crucial for detecting material degradation and maintaining the structural integrity of nuclear systems to ensure both safety and operational efficiency. Traditional physical sensor systems face limitations such as installation challenges, high costs, and difficulties in measuring critical parameters in hard-to-reach or harsh environments, often resulting in incomplete data coverage. Machine learning-driven virtual sensors offer a promising solution by enhancing physical sensor capabilities to monitor critical degradation indicators like pressure, velocity, and turbulence. However, conventional machine learning models struggle with real-time monitoring due to the high-dimensional nature of reactor data and the need for frequent retraining. This paper explores the use of Deep Operator Networks (DeepONet) within a digital twin (DT) framework to predict key thermal-hydraulic parameters in the hot leg of an AP-1000 Pressurized Water Reactor (PWR). In this study, DeepONet is trained with different operational conditions, which relaxes the requirement of continuous retraining, making it suitable for online and real-time prediction components for DT. Our results show that DeepONet achieves accurate predictions with low mean squared error and relative L2 error and can make predictions on unknown data 160,000 times faster than traditional finite element (FE) simulations. This speed and accuracy make DeepONet a powerful tool for tracking conditions that contribute to material degradation in real-time, enhancing reactor safety and longevity.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge