Syed Alam

Physics-Informed Multi-Stage Deep Learning Framework Development for Digital Twin-Centred State-Based Reactor Power Prediction

Nov 24, 2022

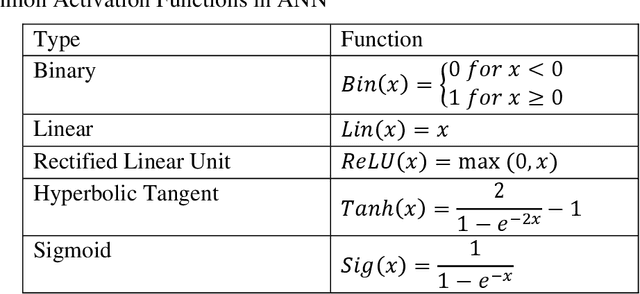

Abstract:Computationally efficient and trustworthy machine learning algorithms are necessary for Digital Twin (DT) framework development. Generally speaking, DT-enabling technologies consist of five major components: (i) Machine learning (ML)-driven prediction algorithm, (ii) Temporal synchronization between physics and digital assets utilizing advanced sensors/instrumentation, (iii) uncertainty propagation, and (iv) DT operational framework. Unfortunately, there is still a significant gap in developing those components for nuclear plant operation. In order to address this gap, this study specifically focuses on the "ML-driven prediction algorithms" as a viable component for the nuclear reactor operation while assessing the reliability and efficacy of the proposed model. Therefore, as a DT prediction component, this study develops a multi-stage predictive model consisting of two feedforward Deep Learning using Neural Networks (DNNs) to determine the final steady-state power of a reactor transient for a nuclear reactor/plant. The goal of the multi-stage model architecture is to convert probabilistic classification to continuous output variables to improve reliability and ease of analysis. Four regression models are developed and tested with input from the first stage model to predict a single value representing the reactor power output. The combined model yields 96% classification accuracy for the first stage and 92% absolute prediction accuracy for the second stage. The development procedure is discussed so that the method can be applied generally to similar systems. An analysis of the role similar models would fill in DTs is performed.

Uncertainty Quantification and Sensitivity analysis for Digital Twin Enabling Technology: Application for BISON Fuel Performance Code

Oct 14, 2022

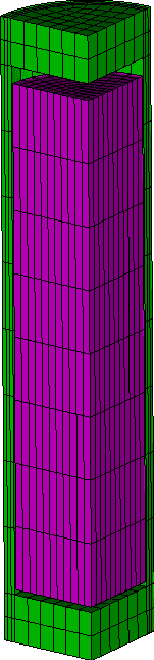

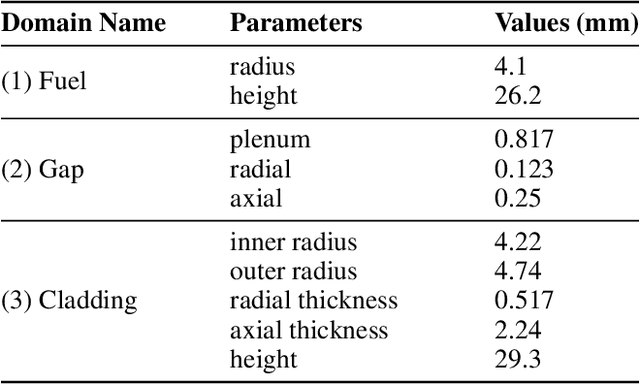

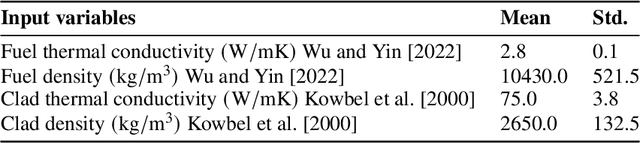

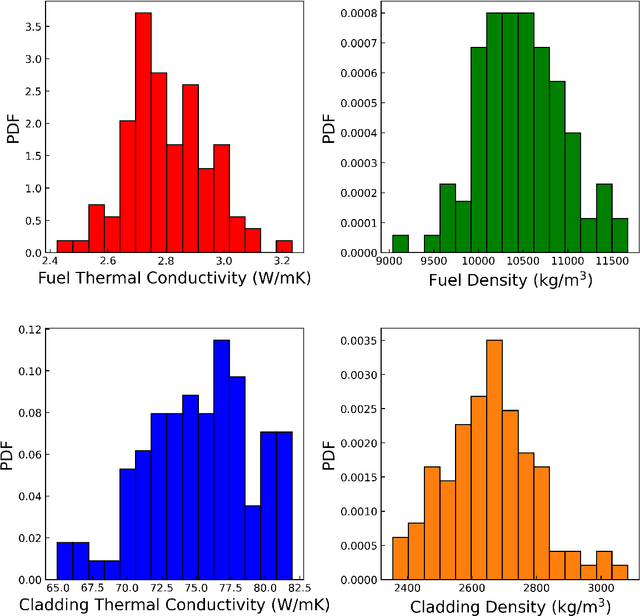

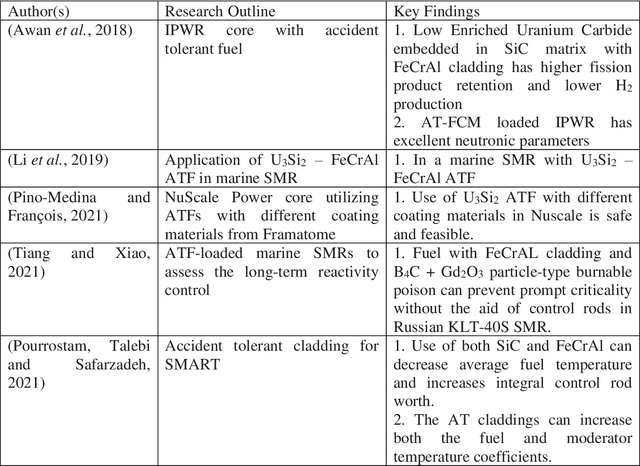

Abstract:To understand the potential of intelligent confirmatory tools, the U.S. Nuclear Regulatory Committee (NRC) initiated a future-focused research project to assess the regulatory viability of machine learning (ML) and artificial intelligence (AI)-driven Digital Twins (DTs) for nuclear power applications. Advanced accident tolerant fuel (ATF) is one of the priority focus areas of the U.S. Department of Energy (DOE). A DT framework can offer game-changing yet practical and informed solutions to the complex problem of qualifying advanced ATFs. Considering the regulatory standpoint of the modeling and simulation (M&S) aspect of DT, uncertainty quantification and sensitivity analysis are paramount to the DT framework's success in terms of multi-criteria and risk-informed decision-making. This chapter introduces the ML-based uncertainty quantification and sensitivity analysis methods while exhibiting actual applications to the finite element-based nuclear fuel performance code BISON.

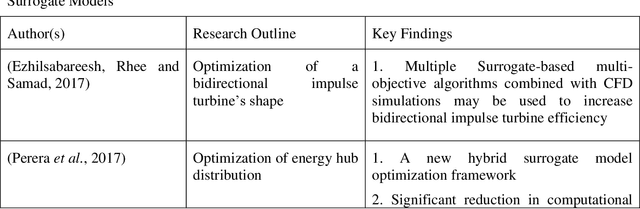

Digital Twin and Artificial Intelligence Incorporated With Surrogate Modeling for Hybrid and Sustainable Energy Systems

Sep 30, 2022

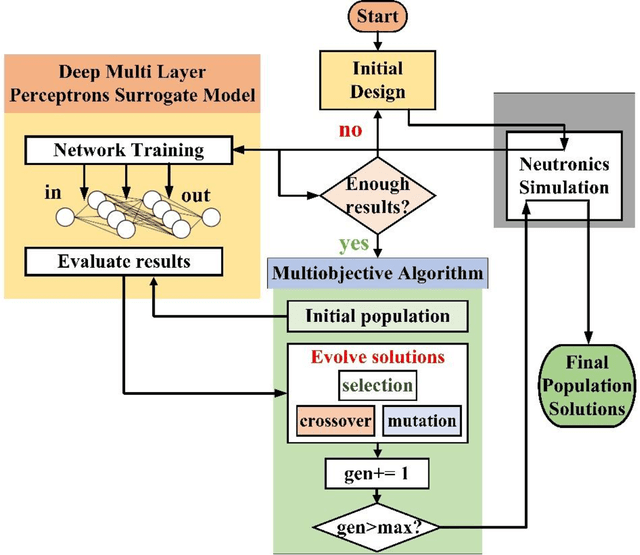

Abstract:Surrogate modeling has brought about a revolution in computation in the branches of science and engineering. Backed by Artificial Intelligence, a surrogate model can present highly accurate results with a significant reduction in computation time than computer simulation of actual models. Surrogate modeling techniques have found their use in numerous branches of science and engineering, energy system modeling being one of them. Since the idea of hybrid and sustainable energy systems is spreading rapidly in the modern world for the paradigm of the smart energy shift, researchers are exploring the future application of artificial intelligence-based surrogate modeling in analyzing and optimizing hybrid energy systems. One of the promising technologies for assessing applicability for the energy system is the digital twin, which can leverage surrogate modeling. This work presents a comprehensive framework/review on Artificial Intelligence-driven surrogate modeling and its applications with a focus on the digital twin framework and energy systems. The role of machine learning and artificial intelligence in constructing an effective surrogate model is explained. After that, different surrogate models developed for different sustainable energy sources are presented. Finally, digital twin surrogate models and associated uncertainties are described.

Leveraging Industry 4.0 -- Deep Learning, Surrogate Model and Transfer Learning with Uncertainty Quantification Incorporated into Digital Twin for Nuclear System

Sep 30, 2022Abstract:Industry 4.0 targets the conversion of the traditional industries into intelligent ones through technological revolution. This revolution is only possible through innovation, optimization, interconnection, and rapid decision-making capability. Numerical models are believed to be the key components of Industry 4.0, facilitating quick decision-making through simulations instead of costly experiments. However, numerical investigation of precise, high-fidelity models for optimization or decision-making is usually time-consuming and computationally expensive. In such instances, data-driven surrogate models are excellent substitutes for fast computational analysis and the probabilistic prediction of the output parameter for new input parameters. The emergence of Internet of Things (IoT) and Machine Learning (ML) has made the concept of surrogate modeling even more viable. However, these surrogate models contain intrinsic uncertainties, originate from modeling defects, or both. These uncertainties, if not quantified and minimized, can produce a skewed result. Therefore, proper implementation of uncertainty quantification techniques is crucial during optimization, cost reduction, or safety enhancement processes analysis. This chapter begins with a brief overview of the concept of surrogate modeling, transfer learning, IoT and digital twins. After that, a detailed overview of uncertainties, uncertainty quantification frameworks, and specifics of uncertainty quantification methodologies for a surrogate model linked to a digital twin is presented. Finally, the use of uncertainty quantification approaches in the nuclear industry has been addressed.

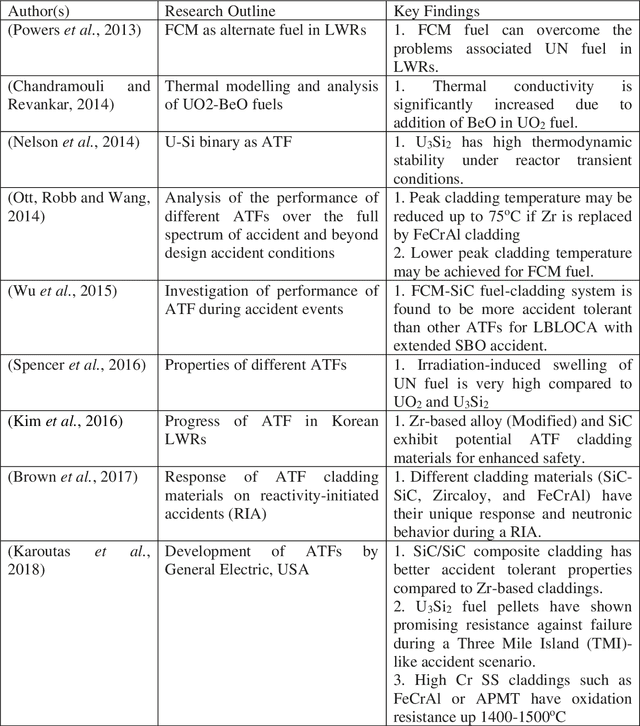

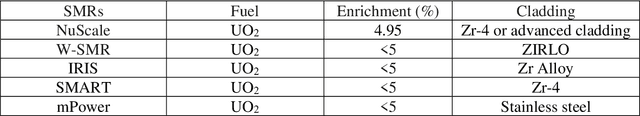

Machine Learning and Artificial Intelligence-Driven Multi-Scale Modeling for High Burnup Accident-Tolerant Fuels for Light Water-Based SMR Applications

Sep 25, 2022

Abstract:The concept of small modular reactor has changed the outlook for tackling future energy crises. This new reactor technology is very promising considering its lower investment requirements, modularity, design simplicity, and enhanced safety features. The application of artificial intelligence-driven multi-scale modeling (neutronics, thermal hydraulics, fuel performance, etc.) incorporating Digital Twin and associated uncertainties in the research of small modular reactors is a recent concept. In this work, a comprehensive study is conducted on the multiscale modeling of accident-tolerant fuels. The application of these fuels in the light water-based small modular reactors is explored. This chapter also focuses on the application of machine learning and artificial intelligence in the design optimization, control, and monitoring of small modular reactors. Finally, a brief assessment of the research gap on the application of artificial intelligence to the development of high burnup composite accident-tolerant fuels is provided. Necessary actions to fulfill these gaps are also discussed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge