Spyros Theodoropoulos

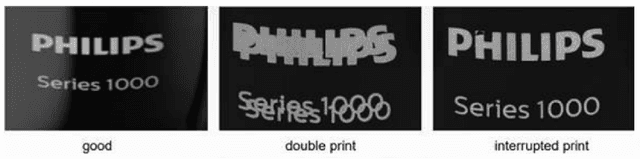

Synthetic Data Augmentation Using GAN For Improved Automated Visual Inspection

Dec 19, 2022

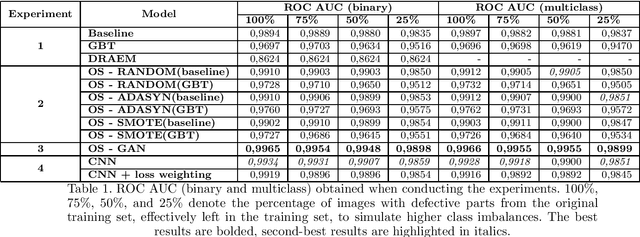

Abstract:Quality control is a crucial activity performed by manufacturing companies to ensure their products conform to the requirements and specifications. The introduction of artificial intelligence models enables to automate the visual quality inspection, speeding up the inspection process and ensuring all products are evaluated under the same criteria. In this research, we compare supervised and unsupervised defect detection techniques and explore data augmentation techniques to mitigate the data imbalance in the context of automated visual inspection. Furthermore, we use Generative Adversarial Networks for data augmentation to enhance the classifiers' discriminative performance. Our results show that state-of-the-art unsupervised defect detection does not match the performance of supervised models but can be used to reduce the labeling workload by more than 50%. Furthermore, the best classification performance was achieved considering GAN-based data generation with AUC ROC scores equal to or higher than 0,9898, even when increasing the dataset imbalance by leaving only 25\% of the images denoting defective products. We performed the research with real-world data provided by Philips Consumer Lifestyle BV.

Robust Anomaly Map Assisted Multiple Defect Detection with Supervised Classification Techniques

Dec 19, 2022

Abstract:Industry 4.0 aims to optimize the manufacturing environment by leveraging new technological advances, such as new sensing capabilities and artificial intelligence. The DRAEM technique has shown state-of-the-art performance for unsupervised classification. The ability to create anomaly maps highlighting areas where defects probably lie can be leveraged to provide cues to supervised classification models and enhance their performance. Our research shows that the best performance is achieved when training a defect detection model by providing an image and the corresponding anomaly map as input. Furthermore, such a setting provides consistent performance when framing the defect detection as a binary or multiclass classification problem and is not affected by class balancing policies. We performed the experiments on three datasets with real-world data provided by Philips Consumer Lifestyle BV.

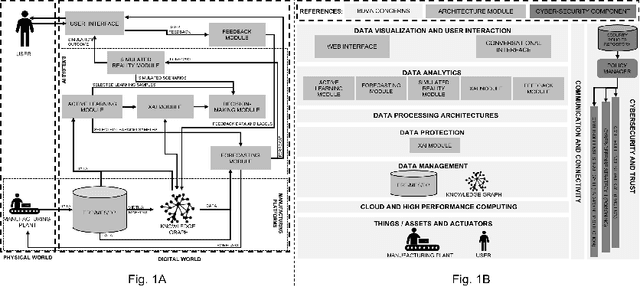

Human-Centric Artificial Intelligence Architecture for Industry 5.0 Applications

Mar 21, 2022

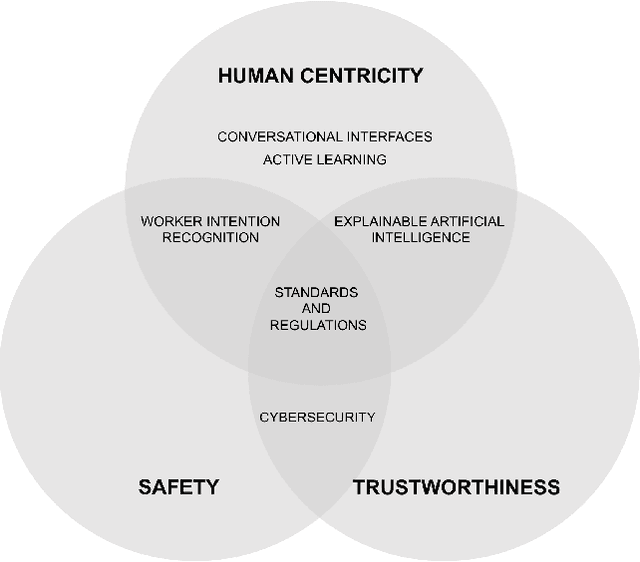

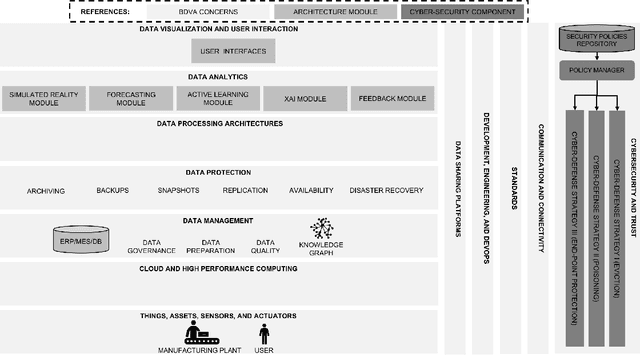

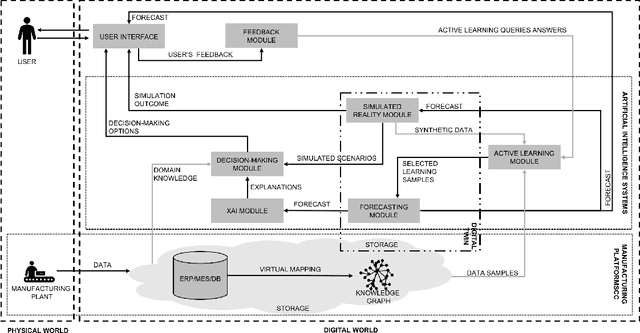

Abstract:Human-centricity is the core value behind the evolution of manufacturing towards Industry 5.0. Nevertheless, there is a lack of architecture that considers safety, trustworthiness, and human-centricity at its core. Therefore, we propose an architecture that integrates Artificial Intelligence (Active Learning, Forecasting, Explainable Artificial Intelligence), simulated reality, decision-making, and users' feedback, focusing on synergies between humans and machines. Furthermore, we align the proposed architecture with the Big Data Value Association Reference Architecture Model. Finally, we validate it on two use cases from real-world case studies.

STARdom: an architecture for trusted and secure human-centered manufacturing systems

Apr 02, 2021

Abstract:There is a lack of a single architecture specification that addresses the needs of trusted and secure Artificial Intelligence systems with humans in the loop, such as human-centered manufacturing systems at the core of the evolution towards Industry 5.0. To realize this, we propose an architecture that integrates forecasts, Explainable Artificial Intelligence, supports collecting users' feedback, and uses Active Learning and Simulated Reality to enhance forecasts and provide decision-making recommendations. The architecture security is addressed as a general concern. We align the proposed architecture with the Big Data Value Association Reference Architecture Model. We tailor it for the domain of demand forecasting and validate it on a real-world case study.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge