Synthetic Data Augmentation Using GAN For Improved Automated Visual Inspection

Paper and Code

Dec 19, 2022

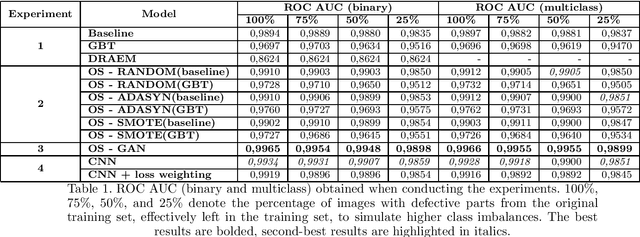

Quality control is a crucial activity performed by manufacturing companies to ensure their products conform to the requirements and specifications. The introduction of artificial intelligence models enables to automate the visual quality inspection, speeding up the inspection process and ensuring all products are evaluated under the same criteria. In this research, we compare supervised and unsupervised defect detection techniques and explore data augmentation techniques to mitigate the data imbalance in the context of automated visual inspection. Furthermore, we use Generative Adversarial Networks for data augmentation to enhance the classifiers' discriminative performance. Our results show that state-of-the-art unsupervised defect detection does not match the performance of supervised models but can be used to reduce the labeling workload by more than 50%. Furthermore, the best classification performance was achieved considering GAN-based data generation with AUC ROC scores equal to or higher than 0,9898, even when increasing the dataset imbalance by leaving only 25\% of the images denoting defective products. We performed the research with real-world data provided by Philips Consumer Lifestyle BV.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge