Shumpei Kubosawa

Soft Sensors and Process Control using AI and Dynamic Simulation

Aug 08, 2022

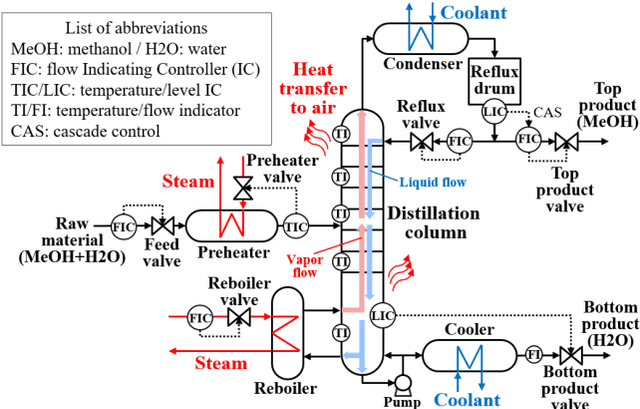

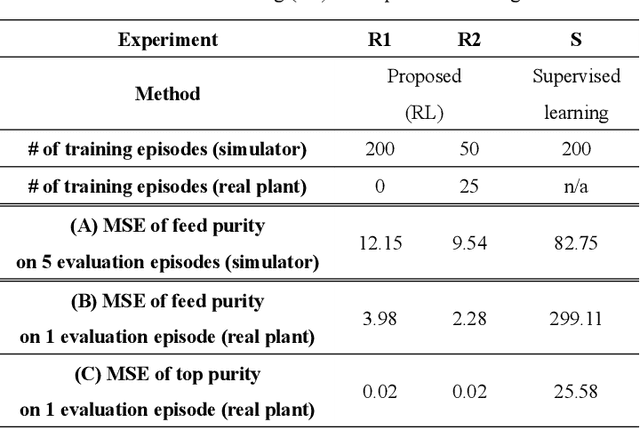

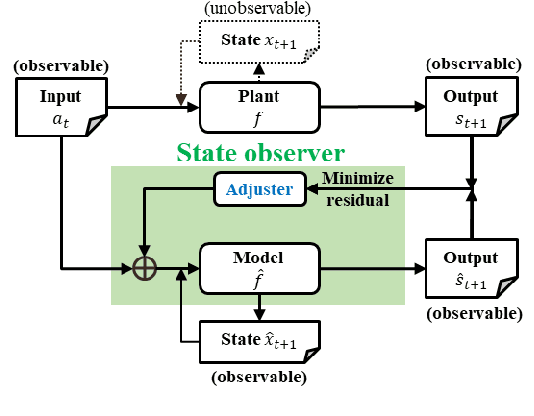

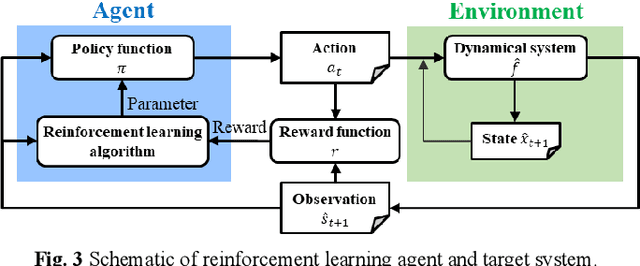

Abstract:During the operation of a chemical plant, product quality must be consistently maintained, and the production of off-specification products should be minimized. Accordingly, process variables related to the product quality, such as the temperature and composition of materials at various parts of the plant must be measured, and appropriate operations (that is, control) must be performed based on the measurements. Some process variables, such as temperature and flow rate, can be measured continuously and instantaneously. However, other variables, such as composition and viscosity, can only be obtained through time-consuming analysis after sampling substances from the plant. Soft sensors have been proposed for estimating process variables that cannot be obtained in real time from easily measurable variables. However, the estimation accuracy of conventional statistical soft sensors, which are constructed from recorded measurements, can be very poor in unrecorded situations (extrapolation). In this study, we estimate the internal state variables of a plant by using a dynamic simulator that can estimate and predict even unrecorded situations on the basis of chemical engineering knowledge and an artificial intelligence (AI) technology called reinforcement learning, and propose to use the estimated internal state variables of a plant as soft sensors. In addition, we describe the prospects for plant operation and control using such soft sensors and the methodology to obtain the necessary prediction models (i.e., simulators) for the proposed system.

* This is an English version of the research paper in Japanese translated by the original authors. The original paper is published in Kagaku Kogaku Ronbunsyu by the Society of Chemical Engineers, Japan (SCEJ) on July 20th, 2022 (DOI: 10.1252/kakoronbunshu.48.141)

Railway Operation Rescheduling System via Dynamic Simulation and Reinforcement Learning

Jan 17, 2022

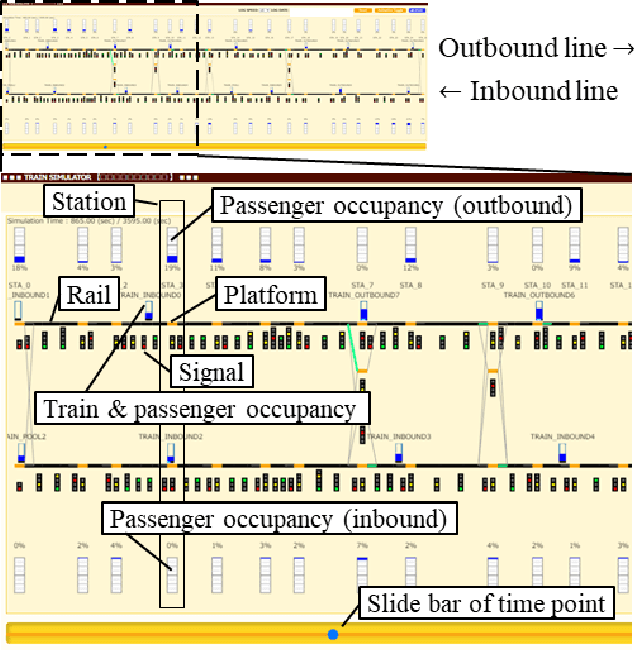

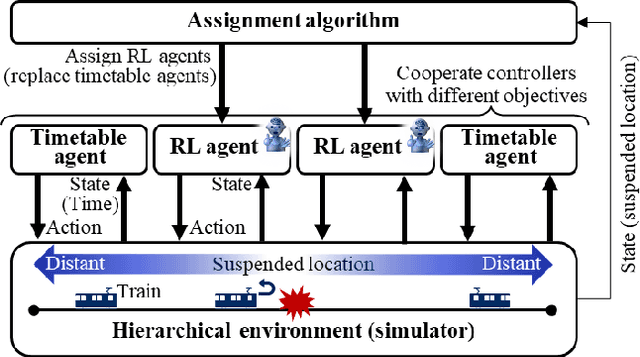

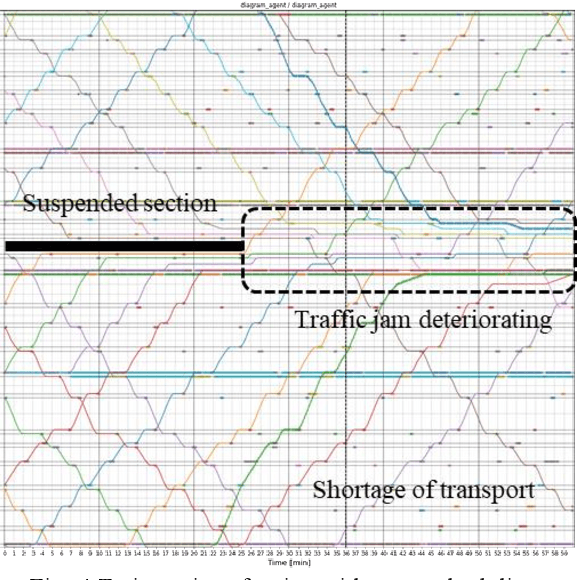

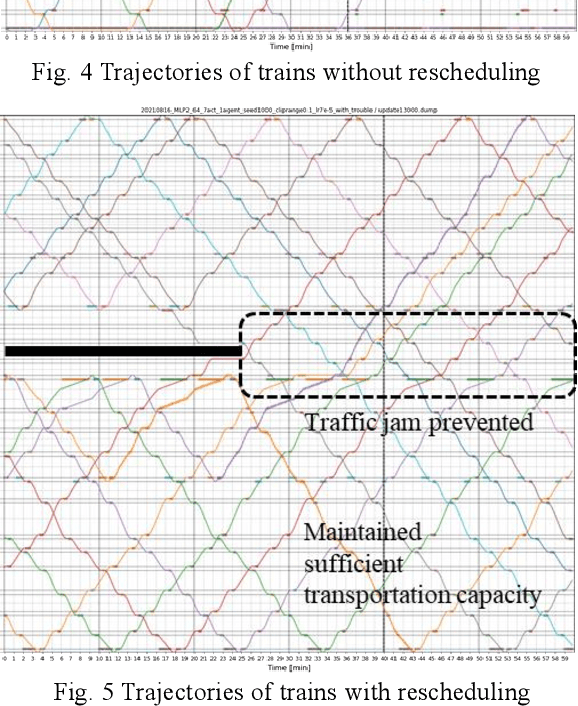

Abstract:The number of railway service disruptions has been increasing owing to intensification of natural disasters. In addition, abrupt changes in social situations such as the COVID-19 pandemic require railway companies to modify the traffic schedule frequently. Therefore, automatic support for optimal scheduling is anticipated. In this study, an automatic railway scheduling system is presented. The system leverages reinforcement learning and a dynamic simulator that can simulate the railway traffic and passenger flow of a whole line. The proposed system enables rapid generation of the traffic schedule of a whole line because the optimization process is conducted in advance as the training. The system is evaluated using an interruption scenario, and the results demonstrate that the system can generate optimized schedules of the whole line in a few minutes.

Synthesizing Chemical Plant Operation Procedures using Knowledge, Dynamic Simulation and Deep Reinforcement Learning

Mar 06, 2019

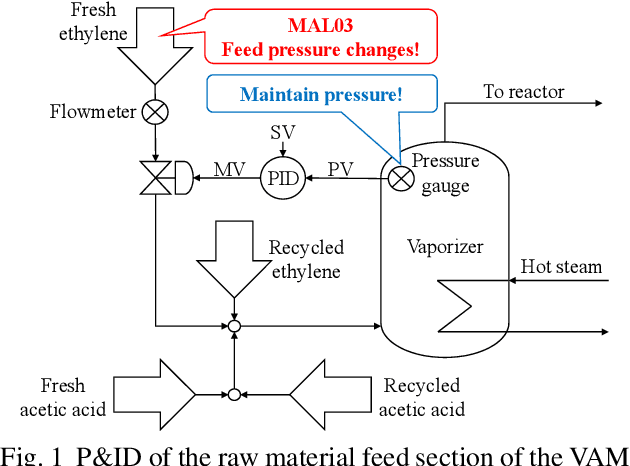

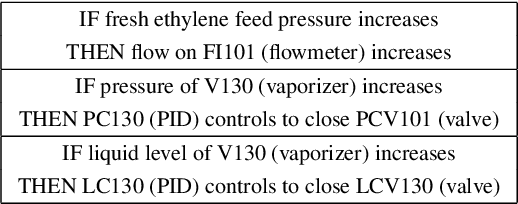

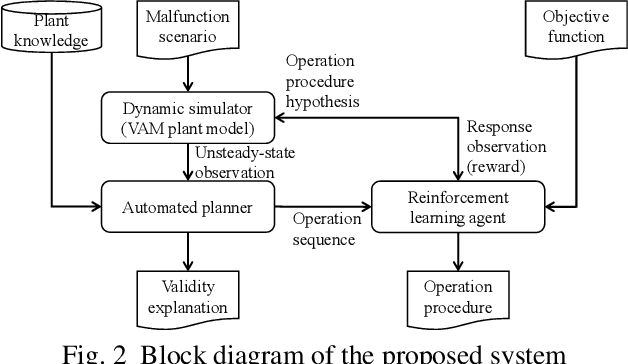

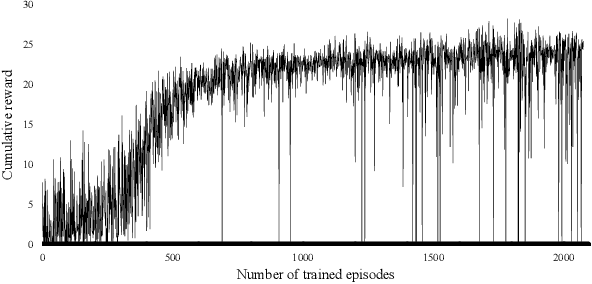

Abstract:Chemical plants are complex and dynamical systems consisting of many components for manipulation and sensing, whose state transitions depend on various factors such as time, disturbance, and operation procedures. For the purpose of supporting human operators of chemical plants, we are developing an AI system that can semi-automatically synthesize operation procedures for efficient and stable operation. Our system can provide not only appropriate operation procedures but also reasons why the procedures are considered to be valid. This is achieved by integrating automated reasoning and deep reinforcement learning technologies with a chemical plant simulator and external knowledge. Our preliminary experimental results demonstrate that it can synthesize a procedure that achieves a much faster recovery from a malfunction compared to standard PID control.

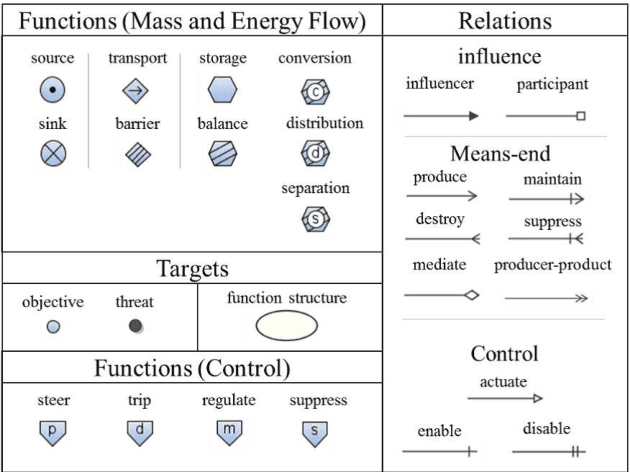

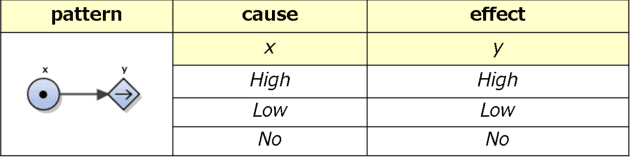

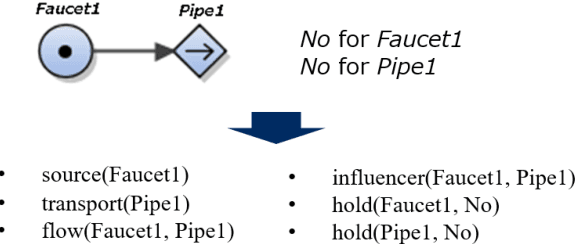

Translating MFM into FOL: towards plant operation planning

Jun 19, 2018

Abstract:This paper proposes a method to translate multilevel flow modeling (MFM) into a first-order language (FOL), which enables the utilisation of logical techniques, such as inference engines and abductive reasoners. An example of this is a planning task for a toy plant that can be solved in FOL using abduction. In addition, owing to the expressivity of FOL, the language is capable of describing actions and their preconditions. This allows the derivation of procedures consisting of multiple actions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge