Soft Sensors and Process Control using AI and Dynamic Simulation

Paper and Code

Aug 08, 2022

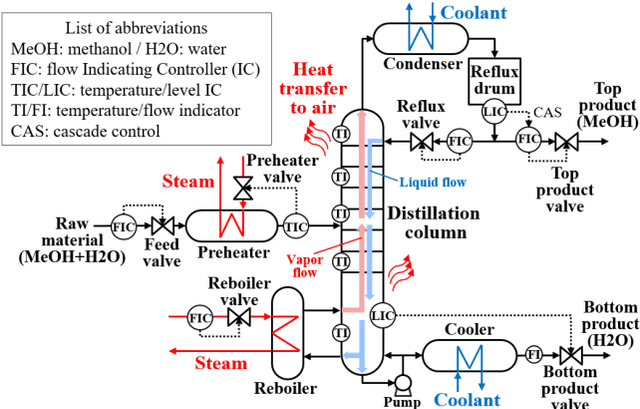

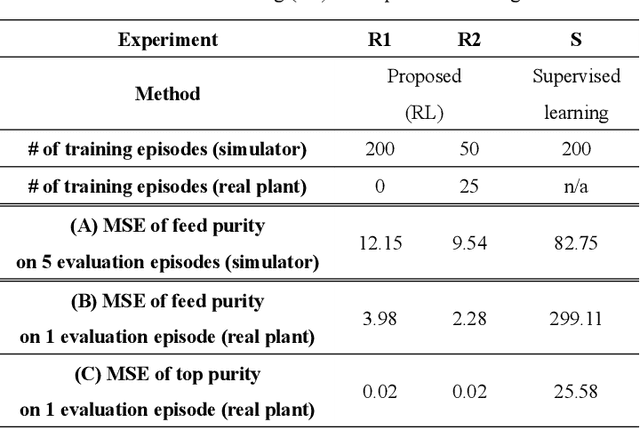

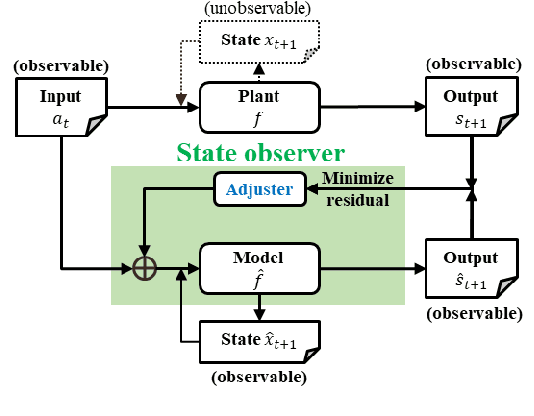

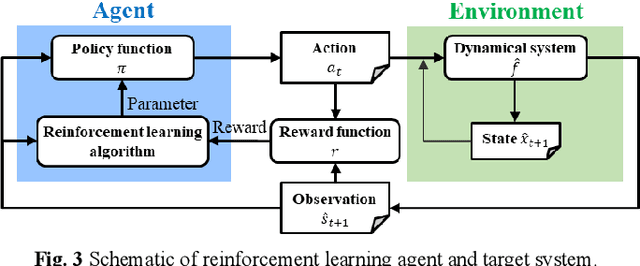

During the operation of a chemical plant, product quality must be consistently maintained, and the production of off-specification products should be minimized. Accordingly, process variables related to the product quality, such as the temperature and composition of materials at various parts of the plant must be measured, and appropriate operations (that is, control) must be performed based on the measurements. Some process variables, such as temperature and flow rate, can be measured continuously and instantaneously. However, other variables, such as composition and viscosity, can only be obtained through time-consuming analysis after sampling substances from the plant. Soft sensors have been proposed for estimating process variables that cannot be obtained in real time from easily measurable variables. However, the estimation accuracy of conventional statistical soft sensors, which are constructed from recorded measurements, can be very poor in unrecorded situations (extrapolation). In this study, we estimate the internal state variables of a plant by using a dynamic simulator that can estimate and predict even unrecorded situations on the basis of chemical engineering knowledge and an artificial intelligence (AI) technology called reinforcement learning, and propose to use the estimated internal state variables of a plant as soft sensors. In addition, we describe the prospects for plant operation and control using such soft sensors and the methodology to obtain the necessary prediction models (i.e., simulators) for the proposed system.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge