Satish Bukkapatnam

DynaMark: A Reinforcement Learning Framework for Dynamic Watermarking in Industrial Machine Tool Controllers

Aug 29, 2025

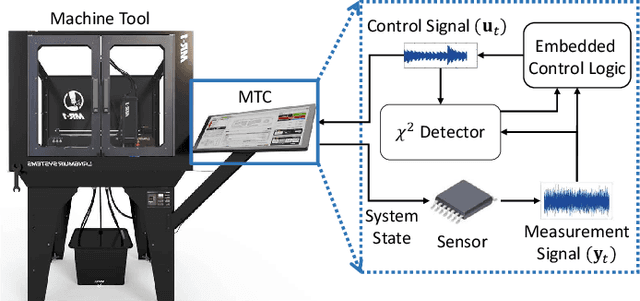

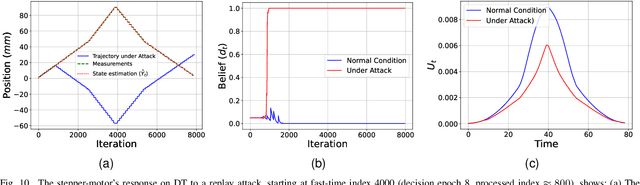

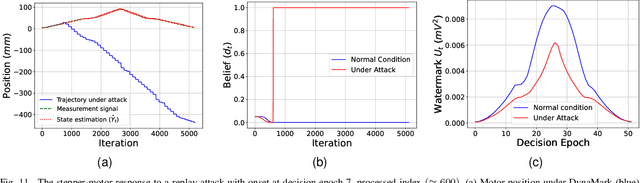

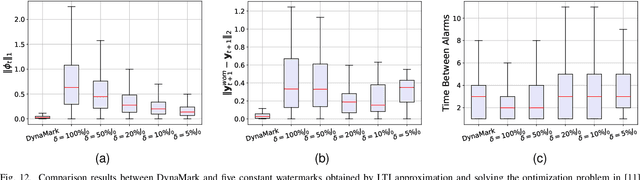

Abstract:Industry 4.0's highly networked Machine Tool Controllers (MTCs) are prime targets for replay attacks that use outdated sensor data to manipulate actuators. Dynamic watermarking can reveal such tampering, but current schemes assume linear-Gaussian dynamics and use constant watermark statistics, making them vulnerable to the time-varying, partly proprietary behavior of MTCs. We close this gap with DynaMark, a reinforcement learning framework that models dynamic watermarking as a Markov decision process (MDP). It learns an adaptive policy online that dynamically adapts the covariance of a zero-mean Gaussian watermark using available measurements and detector feedback, without needing system knowledge. DynaMark maximizes a unique reward function balancing control performance, energy consumption, and detection confidence dynamically. We develop a Bayesian belief updating mechanism for real-time detection confidence in linear systems. This approach, independent of specific system assumptions, underpins the MDP for systems with linear dynamics. On a Siemens Sinumerik 828D controller digital twin, DynaMark achieves a reduction in watermark energy by 70% while preserving the nominal trajectory, compared to constant variance baselines. It also maintains an average detection delay equivalent to one sampling interval. A physical stepper-motor testbed validates these findings, rapidly triggering alarms with less control performance decline and exceeding existing benchmarks.

Machine Learning-Enhanced Prediction of Surface Smoothness for Inertial Confinement Fusion Target Polishing Using Limited Data

Dec 16, 2023Abstract:In Inertial Confinement Fusion (ICF) process, roughly a 2mm spherical shell made of high density carbon is used as target for laser beams, which compress and heat it to energy levels needed for high fusion yield. These shells are polished meticulously to meet the standards for a fusion shot. However, the polishing of these shells involves multiple stages, with each stage taking several hours. To make sure that the polishing process is advancing in the right direction, we are able to measure the shell surface roughness. This measurement, however, is very labor-intensive, time-consuming, and requires a human operator. We propose to use machine learning models that can predict surface roughness based on the data collected from a vibration sensor that is connected to the polisher. Such models can generate surface roughness of the shells in real-time, allowing the operator to make any necessary changes to the polishing for optimal result.

EBLIME: Enhanced Bayesian Local Interpretable Model-agnostic Explanations

Apr 29, 2023

Abstract:We propose EBLIME to explain black-box machine learning models and obtain the distribution of feature importance using Bayesian ridge regression models. We provide mathematical expressions of the Bayesian framework and theoretical outcomes including the significance of ridge parameter. Case studies were conducted on benchmark datasets and a real-world industrial application of locating internal defects in manufactured products. Compared to the state-of-the-art methods, EBLIME yields more intuitive and accurate results, with better uncertainty quantification in terms of deriving the posterior distribution, credible intervals, and rankings of the feature importance.

Unsupervised spectral-band feature identification for optimal process discrimination

Dec 07, 2022

Abstract:Changes in real-world dynamic processes are often described in terms of differences in energies $\textbf{E}(\underline{\alpha})$ of a set of spectral-bands $\underline{\alpha}$. Given continuous spectra of two classes $A$ and $B$, or in general, two stochastic processes $S^{(A)}(f)$ and $S^{(B)}(f)$, $f \in \mathbb{R}^+$, we address the ubiquitous problem of identifying a subset of intervals of $f$ called spectral-bands $\underline{\alpha} \subset \mathbb{R}^+$ such that the energies $\textbf{E}(\underline{\alpha})$ of these bands can optimally discriminate between the two classes. We introduce EGO-MDA, an unsupervised method to identify optimal spectral-bands $\underline{\alpha}^*$ for given samples of spectra from two classes. EGO-MDA employs a statistical approach that iteratively minimizes an adjusted multinomial log-likelihood (deviance) criterion $\mathcal{D}(\underline{\alpha},\mathcal{M})$. Here, Mixture Discriminant Analysis (MDA) aims to derive MLE of two GMM distribution parameters, i.e., $\mathcal{M}^* = \underset{\mathcal{M}}{\rm argmin}~\mathcal{D}(\underline{\alpha}, \mathcal{M})$ and identify a classifier that optimally discriminates between two classes for a given spectral representation. The Efficient Global Optimization (EGO) finds the spectral-bands $\underline{\alpha}^* = \underset{\underline{\alpha}}{\rm argmin}~\mathcal{D}(\underline{\alpha},\mathcal{M})$ for given GMM parameters $\mathcal{M}$. For pathological cases of low separation between mixtures and model misspecification, we discuss the effect of the sample size and the number of iterations on the estimates of parameters $\mathcal{M}$ and therefore the classifier performance. A case study on a synthetic data set is provided. In an engineering application of optimal spectral-banding for anomaly tracking, EGO-MDA achieved at least 70% improvement in the median deviance relative to other methods tested.

Towards Futuristic Autonomous Experimentation--A Surprise-Reacting Sequential Experiment Policy

Dec 01, 2021

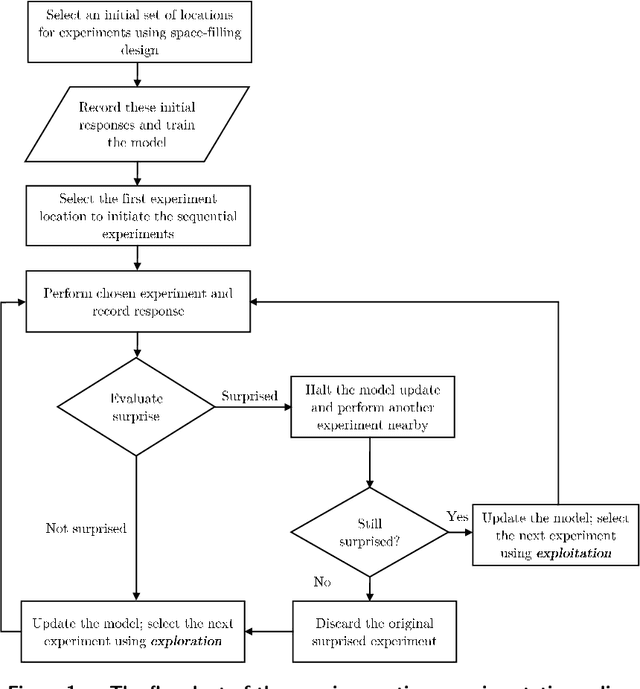

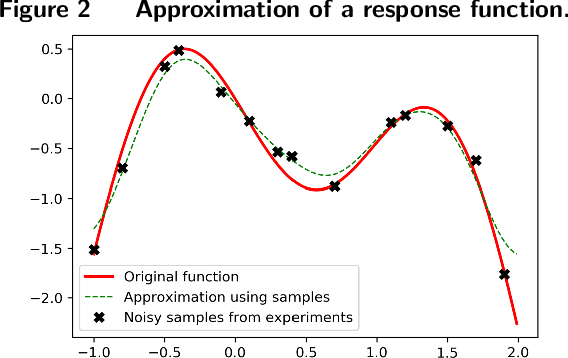

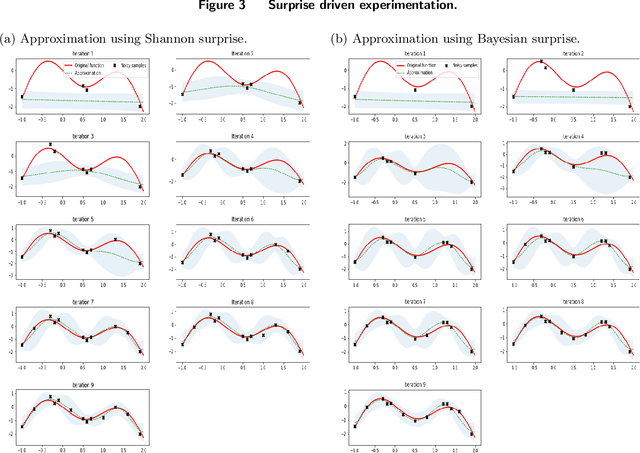

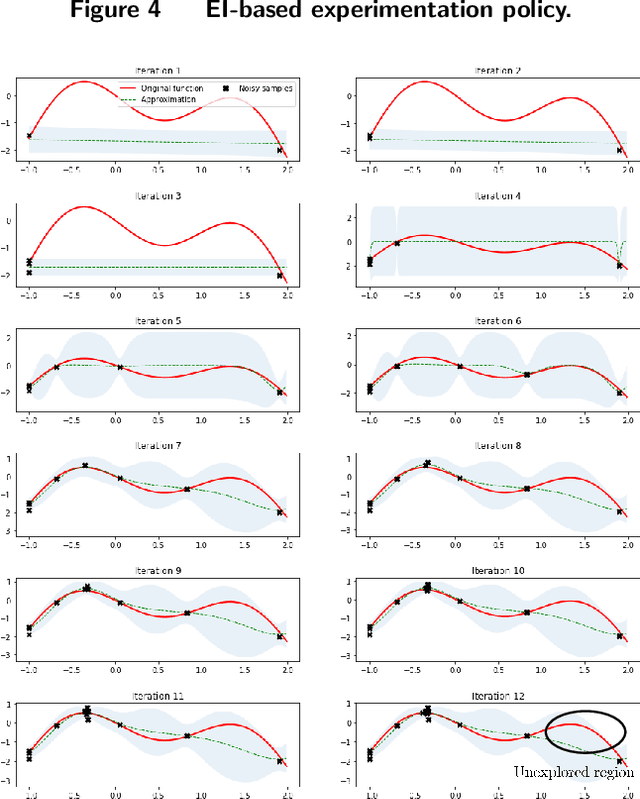

Abstract:An autonomous experimentation platform in manufacturing is supposedly capable of conducting a sequential search for finding suitable manufacturing conditions for advanced materials by itself or even for discovering new materials with minimal human intervention. The core of the intelligent control of such platforms is the policy directing sequential experiments, namely, to decide where to conduct the next experiment based on what has been done thus far. Such policy inevitably trades off exploitation versus exploration and the current practice is under the Bayesian optimization framework using the expected improvement criterion or its variants. We discuss whether it is beneficial to trade off exploitation versus exploration by measuring the element and degree of surprise associated with the immediate past observation. We devise a surprise-reacting policy using two existing surprise metrics, known as the Shannon surprise and Bayesian surprise. Our analysis shows that the surprise-reacting policy appears to be better suited for quickly characterizing the overall landscape of a response surface or a design place under resource constraints. We argue that such capability is much needed for futuristic autonomous experimentation platforms. We do not claim that we have a fully autonomous experimentation platform, but believe that our current effort sheds new lights or provides a different view angle as researchers are racing to elevate the autonomy of various primitive autonomous experimentation systems.

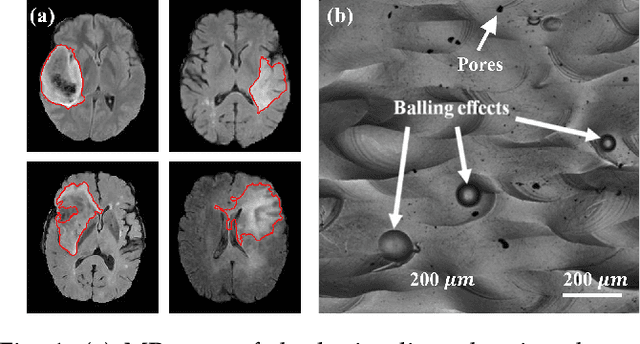

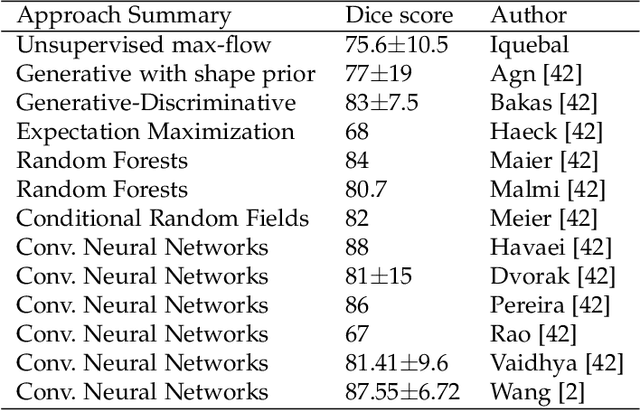

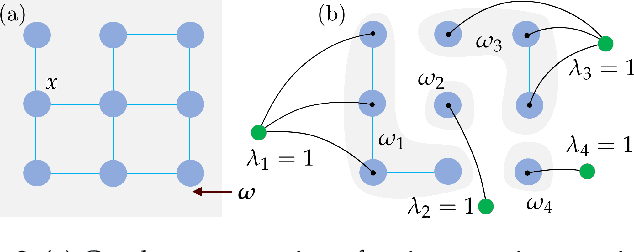

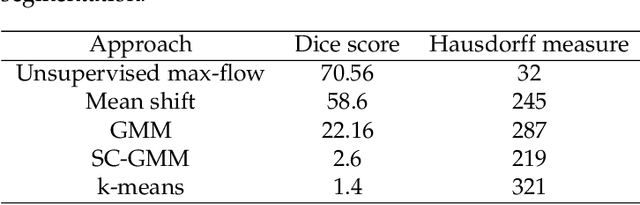

Unsupervised image segmentation via maximum a posteriori estimation of continuous max-flow

Nov 01, 2018

Abstract:Recent thrust in imaging capabilities in medical as well as emerging areas of manufacturing systems creates unique opportunities and challenges for on-the-fly, unsupervised estimation of anomalies and other regions of interest. With the ever-growing image database, it is remarkably costly to create annotations and atlases associated with different combinations of imaging capabilities and regions of interest. To address this issue, we present an unsupervised learning approach to a continuous max-flow problem. We show that the maximum a posteriori estimation of the image labels can be formulated as a capacitated max-flow problem over a continuous domain with unknown flow capacities. The flow capacities are then iteratively obtained by considering a Markov random field prior over the neighborhood structure in the image. We also present results to establish the consistency of the proposed approach. We establish the performance of our approach on two real-world datasets including, brain tumor segmentation and defect identification in additively manufactured surfaces as gathered from electron microscopic images. We also present an exhaustive comparison with other state-of-the-art supervised as well as unsupervised algorithms. Results suggest that the method is able to perform almost comparable to other supervised approaches, but more 90% improvement in terms of Dice score as compared to other unsupervised methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge