Ruturaj Reddy

Drive As You Like: Strategy-Level Motion Planning Based on A Multi-Head Diffusion Model

Aug 23, 2025Abstract:Recent advances in motion planning for autonomous driving have led to models capable of generating high-quality trajectories. However, most existing planners tend to fix their policy after supervised training, leading to consistent but rigid driving behaviors. This limits their ability to reflect human preferences or adapt to dynamic, instruction-driven demands. In this work, we propose a diffusion-based multi-head trajectory planner(M-diffusion planner). During the early training stage, all output heads share weights to learn to generate high-quality trajectories. Leveraging the probabilistic nature of diffusion models, we then apply Group Relative Policy Optimization (GRPO) to fine-tune the pre-trained model for diverse policy-specific behaviors. At inference time, we incorporate a large language model (LLM) to guide strategy selection, enabling dynamic, instruction-aware planning without switching models. Closed-loop simulation demonstrates that our post-trained planner retains strong planning capability while achieving state-of-the-art (SOTA) performance on the nuPlan val14 benchmark. Open-loop results further show that the generated trajectories exhibit clear diversity, effectively satisfying multi-modal driving behavior requirements. The code and related experiments will be released upon acceptance of the paper.

Modified LAB Algorithm with Clustering-based Search Space Reduction Method for solving Engineering Design Problems

Oct 04, 2023

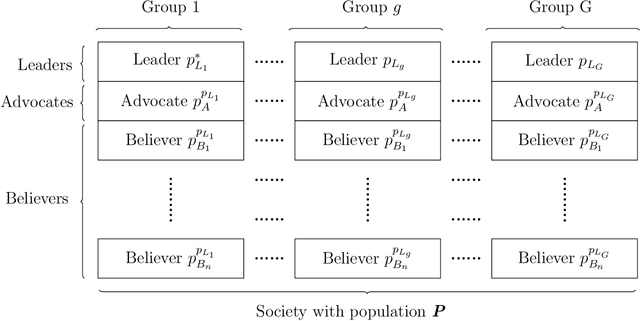

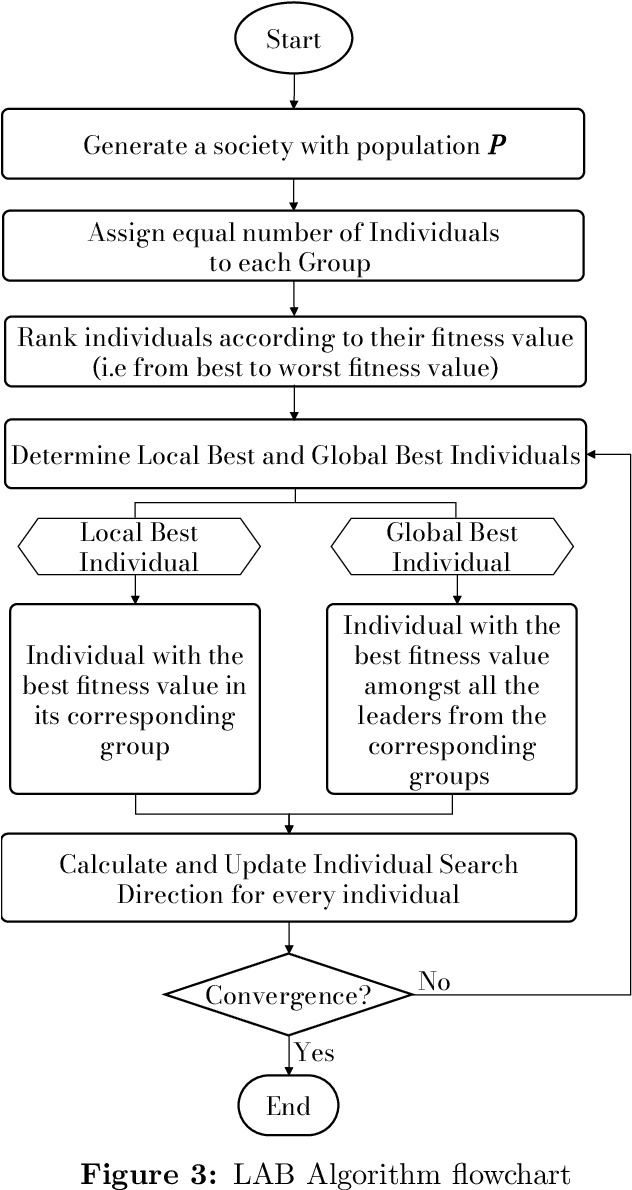

Abstract:A modified LAB algorithm is introduced in this paper. It builds upon the original LAB algorithm (Reddy et al. 2023), which is a socio-inspired algorithm that models competitive and learning behaviours within a group, establishing hierarchical roles. The proposed algorithm incorporates the roulette wheel approach and a reduction factor introducing inter-group competition and iteratively narrowing down the sample space. The algorithm is validated by solving the benchmark test problems from CEC 2005 and CEC 2017. The solutions are validated using standard statistical tests such as two-sided and pairwise signed rank Wilcoxon test and Friedman rank test. The algorithm exhibited improved and superior robustness as well as search space exploration capabilities. Furthermore, a Clustering-Based Search Space Reduction (C-SSR) method is proposed, making the algorithm capable to solve constrained problems. The C-SSR method enables the algorithm to identify clusters of feasible regions, satisfying the constraints and contributing to achieve the optimal solution. This method demonstrates its effectiveness as a potential alternative to traditional constraint handling techniques. The results obtained using the Modified LAB algorithm are then compared with those achieved by other recent metaheuristic algorithms.

LAB: A Leader-Advocate-Believer Based Optimization Algorithm

Apr 23, 2022

Abstract:This manuscript introduces a new socio-inspired metaheuristic technique referred to as Leader-Advocate-Believer based optimization algorithm (LAB) for engineering and global optimization problems. The proposed algorithm is inspired by the AI-based competitive behaviour exhibited by the individuals in a group while simultaneously improving themselves and establishing a role (Leader, Advocate, Believer). LAB performance in computational time and function evaluations are benchmarked using other metaheuristic algorithms. Besides benchmark problems, the LAB algorithm was applied for solving challenging engineering problems, including abrasive water jet machining, electric discharge machining, micro-machining processes, and process parameter optimization for turning titanium alloy in a minimum quantity lubrication environment. The results were superior to the other algorithms compared such as Firefly Algorithm, Variations of Co-hort Intelligence, Genetic Algorithm, Simulated Annealing, Particle Swarm Optimisation, and Multi-Cohort Intelligence. The results from this study highlighted that the LAB outperforms the other algorithms in terms of function evaluations and computational time. The prominent features of the LAB algorithm along with its limitations are also discussed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge