Robert van Liere

X-ray Image Generation as a Method of Performance Prediction for Real-Time Inspection: a Case Study

Jan 30, 2024Abstract:X-ray imaging can be efficiently used for high-throughput in-line inspection of industrial products. However, designing a system that satisfies industrial requirements and achieves high accuracy is a challenging problem. The effect of many system settings is application-specific and difficult to predict in advance. Consequently, the system is often configured using empirical rules and visual observations. The performance of the resulting system is characterized by extensive experimental testing. We propose to use computational methods to substitute real measurements with generated images corresponding to the same experimental settings. With this approach, it is possible to observe the influence of experimental settings on a large amount of data and to make a prediction of the system performance faster than with conventional methods. We argue that a high accuracy of the image generator may be unnecessary for an accurate performance prediction. We propose a quantitative methodology to characterize the quality of the generation model using POD curves. The proposed approach can be adapted to various applications and we demonstrate it on the poultry inspection problem. We show how a calibrated image generation model can be used to quantitatively evaluate the effect of the X-ray exposure time on the performance of the inspection system.

Detecting internal disorders in fruit by CT. Part 1: Joint 2D to 3D image registration workflow for comparing multiple slice photographs and CT scans of apple fruit

Oct 03, 2023Abstract:A large percentage of apples are affected by internal disorders after long-term storage, which makes them unacceptable in the supply chain. CT imaging is a promising technique for in-line detection of these disorders. Therefore, it is crucial to understand how different disorders affect the image features that can be observed in CT scans. This paper presents a workflow for creating datasets of image pairs of photographs of apple slices and their corresponding CT slices. By having CT and photographic images of the same part of the apple, the complementary information in both images can be used to study the processes underlying internal disorders and how internal disorders can be measured in CT images. The workflow includes data acquisition, image segmentation, image registration, and validation methods. The image registration method aligns all available slices of an apple within a single optimization problem, assuming that the slices are parallel. This method outperformed optimizing the alignment separately for each slice. The workflow was applied to create a dataset of 1347 slice photographs and their corresponding CT slices. The dataset was acquired from 107 'Kanzi' apples that had been stored in controlled atmosphere (CA) storage for 8 months. In this dataset, the distance between annotations in the slice photograph and the matching CT slice was, on average, $1.47 \pm 0.40$ mm. Our workflow allows collecting large datasets of accurately aligned photo-CT image pairs, which can help distinguish internal disorders with a similar appearance on CT. With slight modifications, a similar workflow can be applied to other fruits or MRI instead of CT scans.

Quantifying the effect of X-ray scattering for data generation in real-time defect detection

May 22, 2023Abstract:X-ray imaging is widely used for non-destructive detection of defects in industrial products on a conveyor belt. Real-time detection requires highly accurate, robust, and fast algorithms to analyze X-ray images. Deep convolutional neural networks (DCNNs) satisfy these requirements if a large amount of labeled data is available. To overcome the challenge of collecting these data, different methods of X-ray image generation can be considered. Depending on the desired level of similarity to real data, various physical effects either should be simulated or can be ignored. X-ray scattering is known to be computationally expensive to simulate, and this effect can heavily influence the accuracy of a generated X-ray image. We propose a methodology for quantitative evaluation of the effect of scattering on defect detection. This methodology compares the accuracy of DCNNs trained on different versions of the same data that include and exclude the scattering signal. We use the Probability of Detection (POD) curves to find the size of the smallest defect that can be detected with a DCNN and evaluate how this size is affected by the choice of training data. We apply the proposed methodology to a model problem of defect detection in cylinders. Our results show that the exclusion of the scattering signal from the training data has the largest effect on the smallest detectable defects. Furthermore, we demonstrate that accurate inspection is more reliant on high-quality training data for images with a high quantity of scattering. We discuss how the presented methodology can be used for other tasks and objects.

A tomographic workflow to enable deep learning for X-ray based foreign object detection

Jan 28, 2022

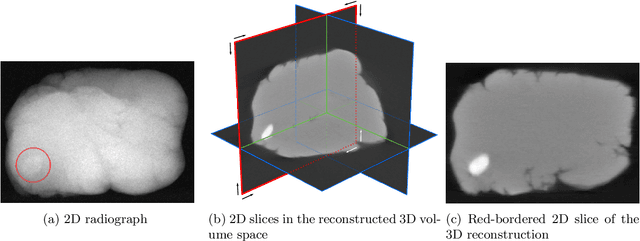

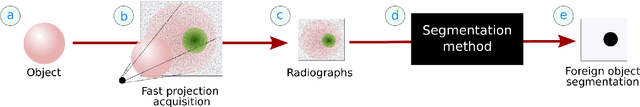

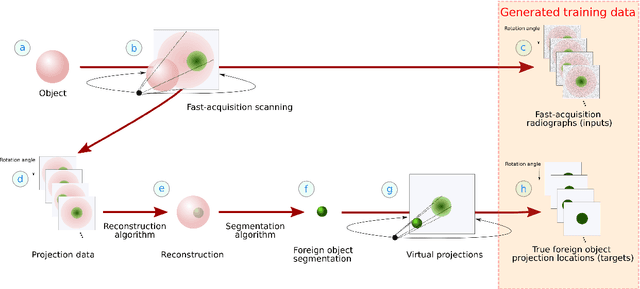

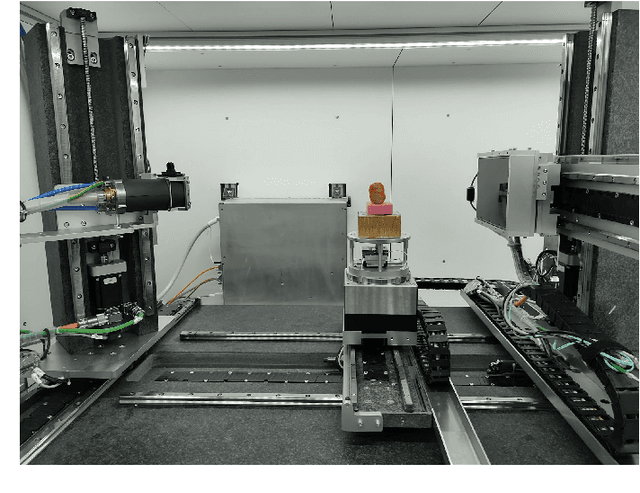

Abstract:Detection of unwanted (`foreign') objects within products is a common procedure in many branches of industry for maintaining production quality. X-ray imaging is a fast, non-invasive and widely applicable method for foreign object detection. Deep learning has recently emerged as a powerful approach for recognizing patterns in radiographs (i.e., X-ray images), enabling automated X-ray based foreign object detection. However, these methods require a large number of training examples and manual annotation of these examples is a subjective and laborious task. In this work, we propose a Computed Tomography (CT) based method for producing training data for supervised learning of foreign object detection, with minimal labour requirements. In our approach, a few representative objects are CT scanned and reconstructed in 3D. The radiographs that have been acquired as part of the CT-scan data serve as input for the machine learning method. High-quality ground truth locations of the foreign objects are obtained through accurate 3D reconstructions and segmentations. Using these segmented volumes, corresponding 2D segmentations are obtained by creating virtual projections. We outline the benefits of objectively and reproducibly generating training data in this way compared to conventional radiograph annotation. In addition, we show how the accuracy depends on the number of objects used for the CT reconstructions. The results show that in this workflow generally only a relatively small number of representative objects (i.e., fewer than 10) are needed to achieve adequate detection performance in an industrial setting. Moreover, for real experimental data we show that the workflow leads to higher foreign object detection accuracies than with standard radiograph annotation.

Unsupervised foreign object detection based on dual-energy absorptiometry in the food industry

Apr 12, 2021

Abstract:X-ray imaging is a widely used technique for non-destructive inspection of agricultural food products. One application of X-ray imaging is the autonomous, in-line detection of foreign objects in food samples. Examples of such inclusions are bone fragments in meat products, plastic and metal debris in fish, fruit infestations. This article presents a processing methodology for unsupervised foreign object detection based on dual-energy X-ray absorptiometry (DEXA). A foreign object is defined as a fragment of material with different X-ray attenuation properties than those belonging to the food product. A novel thickness correction model is introduced as a pre-processing technique for DEXA data. The aim of the model is to homogenize regions in the image that belong to the food product and enhance contrast where the foreign object is present. In this way, the segmentation of the foreign object is more robust to noise and lack of contrast. The proposed methodology was applied to a dataset of 488 samples of meat products. The samples were acquired from a conveyor belt in a food processing factory. Approximately 60\% of the samples contain foreign objects of different types and sizes, while the rest of the samples are void of foreign objects. The results show that samples without foreign objects are correctly identified in 97% of cases, the overall accuracy of foreign object detection reaches 95%.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge