Robert Boute

Prescriptive maintenance with causal machine learning

Jun 03, 2022

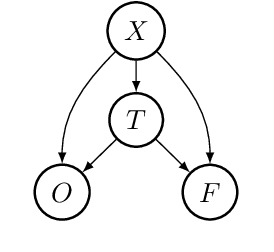

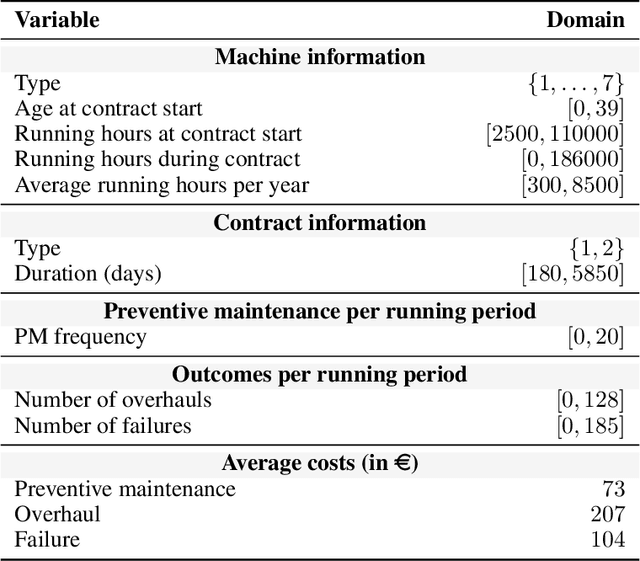

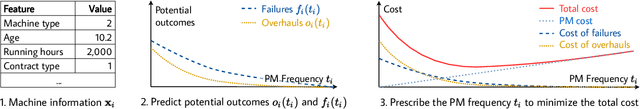

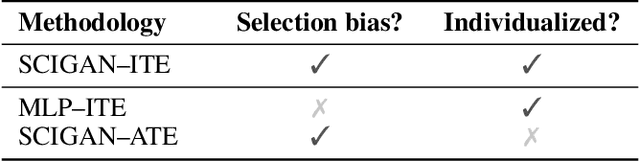

Abstract:Machine maintenance is a challenging operational problem, where the goal is to plan sufficient preventive maintenance to avoid machine failures and overhauls. Maintenance is often imperfect in reality and does not make the asset as good as new. Although a variety of imperfect maintenance policies have been proposed in the literature, these rely on strong assumptions regarding the effect of maintenance on the machine's condition, assuming the effect is (1) deterministic or governed by a known probability distribution, and (2) machine-independent. This work proposes to relax both assumptions by learning the effect of maintenance conditional on a machine's characteristics from observational data on similar machines using existing methodologies for causal inference. By predicting the maintenance effect, we can estimate the number of overhauls and failures for different levels of maintenance and, consequently, optimize the preventive maintenance frequency to minimize the total estimated cost. We validate our proposed approach using real-life data on more than 4,000 maintenance contracts from an industrial partner. Empirical results show that our novel, causal approach accurately predicts the maintenance effect and results in individualized maintenance schedules that are more accurate and cost-effective than supervised or non-individualized approaches.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge