Radoslaw Zimroz

Advancing machine fault diagnosis: A detailed examination of convolutional neural networks

Feb 12, 2025Abstract:The growing complexity of machinery and the increasing demand for operational efficiency and safety have driven the development of advanced fault diagnosis techniques. Among these, convolutional neural networks (CNNs) have emerged as a powerful tool, offering robust and accurate fault detection and classification capabilities. This comprehensive review delves into the application of CNNs in machine fault diagnosis, covering its theoretical foundation, architectural variations, and practical implementations. The strengths and limitations of CNNs are analyzed in this domain, discussing their effectiveness in handling various fault types, data complexities, and operational environments. Furthermore, we explore the evolving landscape of CNN-based fault diagnosis, examining recent advancements in data augmentation, transfer learning, and hybrid architectures. Finally, we highlight future research directions and potential challenges to further enhance the application of CNNs for reliable and proactive machine fault diagnosis.

Local damage detection in rolling element bearings based on a Single Ensemble Empirical Mode Decomposition

Feb 12, 2025Abstract:A Single Ensemble Empirical Mode Decomposition (SEEMD) is proposed for locating the damage in rolling element bearings. The SEEMD does not require a number of ensembles from the addition or subtraction of noise every time while processing the signals. The SEEMD requires just a single sifting process of a modified raw signal to reduce the computation time significantly. The other advantage of the SEEMD method is its success in dealing with non-Gaussian or non-stationary perturbing signals. In SEEMD, initially, a fractional Gaussian noise (FGN) is added to the raw signal to emphasize on high frequencies of the signal. Then, a convoluted white Gaussian noise is multiplied to the resulting signal which changes the spectral content of the signal which helps in extraction of the weak periodic signal. Finally, the obtained signal is decomposed by using a single sifting process. The proposed methodology is applied to the raw signals obtained from the mining industry. These signals are difficult to analyze since cyclic impulsive components are obscured by noise and other interference. Based on the results, the proposed method can effectively detect the fault where the signal of interest (SOI) has been extracted with good quality.

A crayfish-optimized wavelet filter and its application to fault diagnosis

Feb 12, 2025

Abstract:Industrial machine fault diagnosis ensures the reliability and functionality of the system, but identifying informative frequency bands in vibration signals can be challenging due to low signal-to-noise ratio (SNR), background noise, and random interferences. The wavelet filter is commonly used for this purpose, but its parameters are crucial for locating the informative frequency band to extract repetitive transients. This study utilizes a crayfish optimization algorithm (COA) to optimize the wavelet filter adaptively for extracting fault characteristics. COA uses correlated kurtosis (CK) as a fitness function while addressing issues related to inaccurate CK period through an updation process. The proposed methodology is applied to different industrial cases and compared with existing methods, demonstrating its superiority in extracting informative frequencies.

Non-negative tensor factorization for vibration-based local damage detection

Mar 19, 2024Abstract:In this study, a novel non-negative tensor factorization (NTF)-based method for vibration-based local damage detection in rolling element bearings is proposed. As the diagnostic signal registered from a faulty machine is non-stationary, the time-frequency method is frequently used as a primary decomposition technique. It is proposed here to extract multi-linear NTF-based components from a 3D array of time-frequency representations of an observed signal partitioned into blocks. As a result, frequency and temporal informative components can be efficiently separated from non-informative ones. The experiments performed on synthetic and real signals demonstrate the high efficiency of the proposed method with respect to the already known non-negative matrix factorization approach.

An Adaptive feature mode decomposition based on a novel health indicator for bearing fault diagnosis

Mar 19, 2024

Abstract:The vibration analysis of the bearing is very crucial because of its non-stationary nature and low signal-to-noise ratio. Therefore, a novel scheme for detecting bearing defects is put forward based on the extraction of single-valued neutrosophic cross-entropy (SVNCE) to address this issue. Initially, the artificial hummingbird algorithm (AHA) is used to make the feature mode decomposition (FMD) adaptive by optimizing its parameter based on a newly developed health indicator (HI) i.e. sparsity impact measure index (SIMI). This HI ensures full sparsity and impact properties simultaneously. The raw signals are disintegrated into different modes by adaptive FMD at optimal values of its parameters. The energy of these modes is calculated for different health conditions. The energy interval range has been decided based on energy eigen which are then transformed into single-valued neutrosophic sets (SVNSs) for unknown defect conditions. The minimum argument principle employs the least SVNCE values between SVNSs of testing samples (obtained from unknown bearing conditions) and SVNSs of training samples (obtained from known bearing conditions) to recognize the different defects in the bearing. It has been discovered that the suggested methodology is more adept at identifying the various bearing defects.

Bearing damage detection with orthogonal and non-negative low-rank feature extraction

Mar 19, 2024

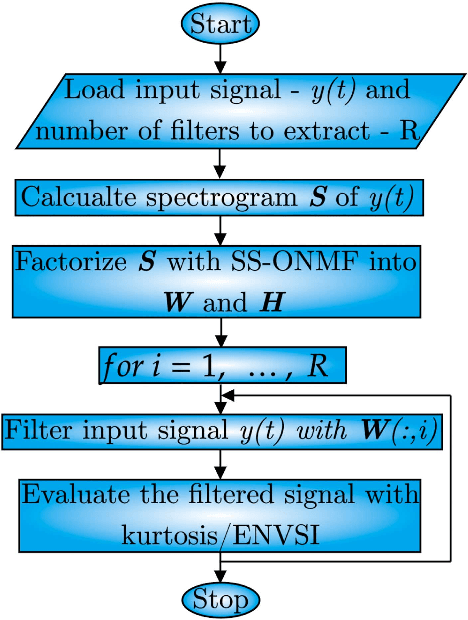

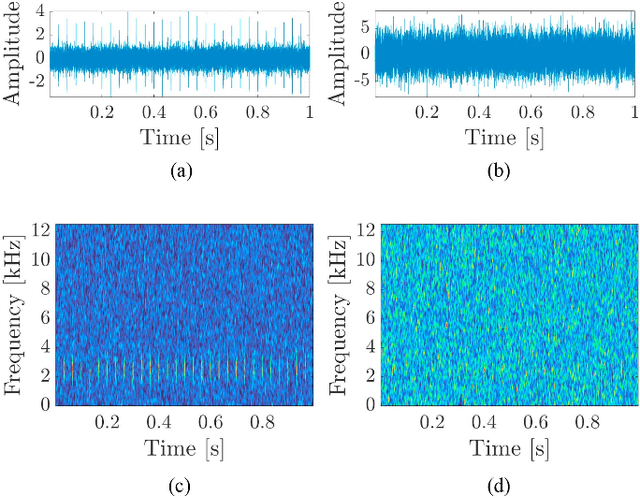

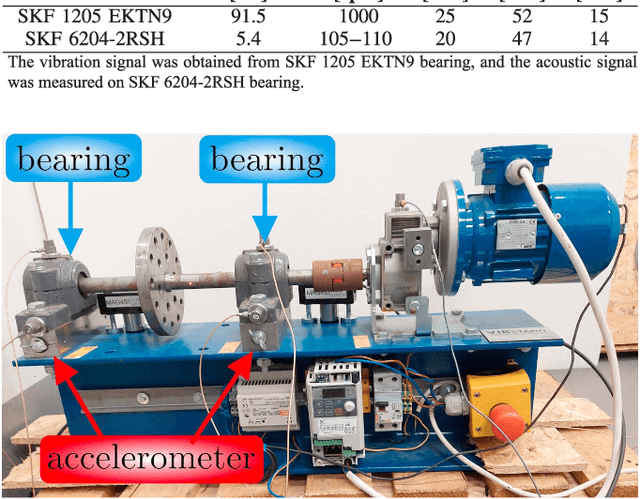

Abstract:Local damage of bearings can be detected as a weak cyclic and impulsive component in a highly noisy measured signal. A key problem is how to extract the signal of interest (SOI) from the raw signal, i.e., how to identify and design an optimal filter. To tackle this problem, we propose to use stochastic sampled orthogonal non-negative matrix factorization for extracting frequency-based features from a spectrogram of the measured signal. The proposed algorithm finds a selective filter that is tailored to the frequency band of the SOI. We show that our approach outperforms the other state-of-the-art selectors that were previously used in condition monitoring. The efficiency of the proposed method is illustrated using both a simulation study and the following real signals: (a) vibration signal from a test rig in the laboratory and (b) acoustic signal from a belt conveyor.

Non-negative matrix underapproximation as optimal frequency band selector

Mar 19, 2024

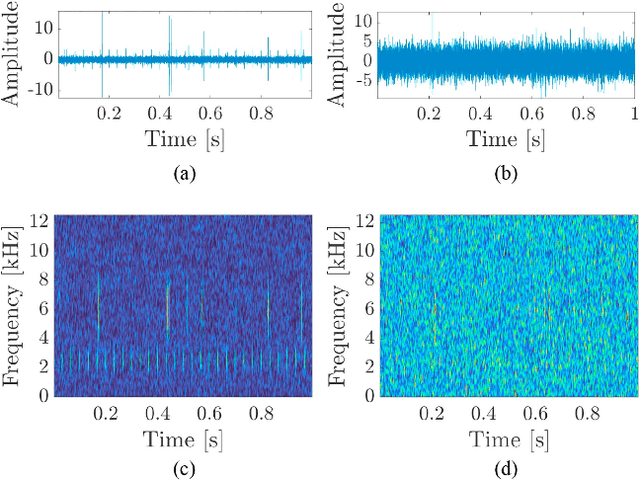

Abstract:Time-frequency representation (TFR) is often used for non-stationary signal analysis. The most intuitive and interpretable TFR is the spectrogram. Recently, a concept of non-negative matrix factorization (NMF) has been successfully applied to local damage detection in rolling elements of bearings via spectrogram factorization. NMF applied to the spectrogram allows one to find an informative frequency band, which could be further used as a filter characteristic. However, the obtained filter characteristics mostly detect the informative frequency band, which also encompasses a lot of noise. In the case where noise is more problematic, as is the case for acoustic signals from industrial machines, the NMF hardly detects the damage. To solve this problem and obtain more selective filters, which are more robust to noise, we propose the non-negative matrix under-approximation (NMU) as an informative frequency band selector. Due to the more sparse parts-based representation of the NMU compared to NMF, NMU provides more selective filter characteristics, which neglect the non-informative frequency bands related to the noise. In practice, it means that NMU gives a better signal-to-noise ratio for the filtered signal. The efficiency of the proposed approach has been validated on the vibration signal from the test rig and the acoustic signal from an idler.

Intelligent fault diagnosis of worm gearbox based on adaptive CNN using amended gorilla troop optimization with quantum gate mutation strategy

Mar 19, 2024

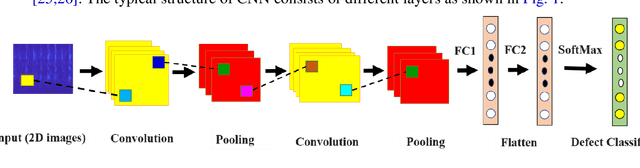

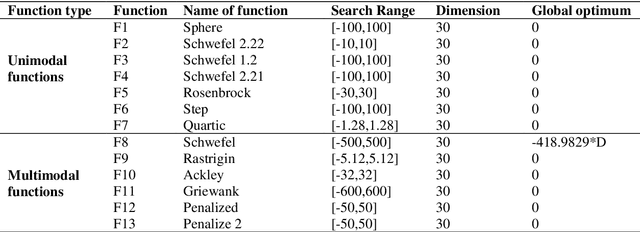

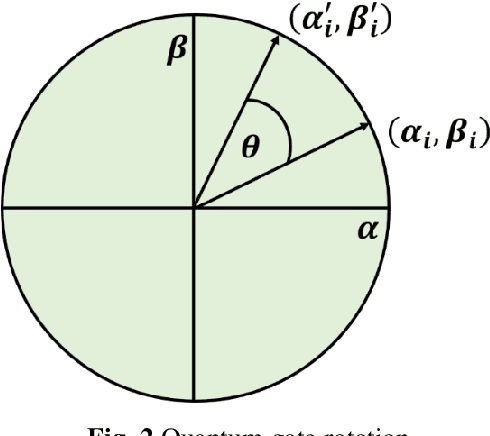

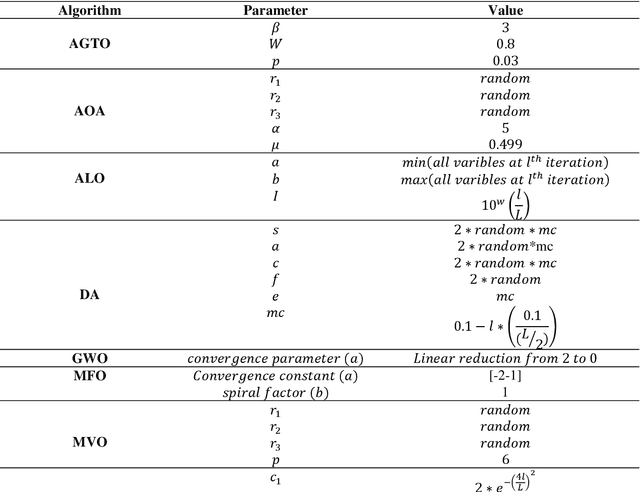

Abstract:The worm gearbox is a high-speed transmission system that plays a vital role in various industries. Therefore it becomes necessary to develop a robust fault diagnosis scheme for worm gearbox. Due to advancements in sensor technology, researchers from academia and industries prefer deep learning models for fault diagnosis purposes. The optimal selection of hyperparameters (HPs) of deep learning models plays a significant role in stable performance. Existing methods mainly focused on manual tunning of these parameters, which is a troublesome process and sometimes leads to inaccurate results. Thus, exploring more sophisticated methods to optimize the HPs automatically is important. In this work, a novel optimization, i.e. amended gorilla troop optimization (AGTO), has been proposed to make the convolutional neural network (CNN) adaptive for extracting the features to identify the worm gearbox defects. Initially, the vibration and acoustic signals are converted into 2D images by the Morlet wavelet function. Then, the initial model of CNN is developed by setting hyperparameters. Further, the search space of each Hp is identified and optimized by the developed AGTO algorithm. The classification accuracy has been evaluated by AGTO-CNN, which is further validated by the confusion matrix. The performance of the developed model has also been compared with other models. The AGTO algorithm is examined on twenty-three classical benchmark functions and the Wilcoxon test which demonstrates the effectiveness and dominance of the developed optimization algorithm. The results obtained suggested that the AGTO-CNN has the highest diagnostic accuracy and is stable and robust while diagnosing the worm gearbox.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge