Agnieszka Wylomanska

Non-negative tensor factorization for vibration-based local damage detection

Mar 19, 2024Abstract:In this study, a novel non-negative tensor factorization (NTF)-based method for vibration-based local damage detection in rolling element bearings is proposed. As the diagnostic signal registered from a faulty machine is non-stationary, the time-frequency method is frequently used as a primary decomposition technique. It is proposed here to extract multi-linear NTF-based components from a 3D array of time-frequency representations of an observed signal partitioned into blocks. As a result, frequency and temporal informative components can be efficiently separated from non-informative ones. The experiments performed on synthetic and real signals demonstrate the high efficiency of the proposed method with respect to the already known non-negative matrix factorization approach.

Bearing damage detection with orthogonal and non-negative low-rank feature extraction

Mar 19, 2024

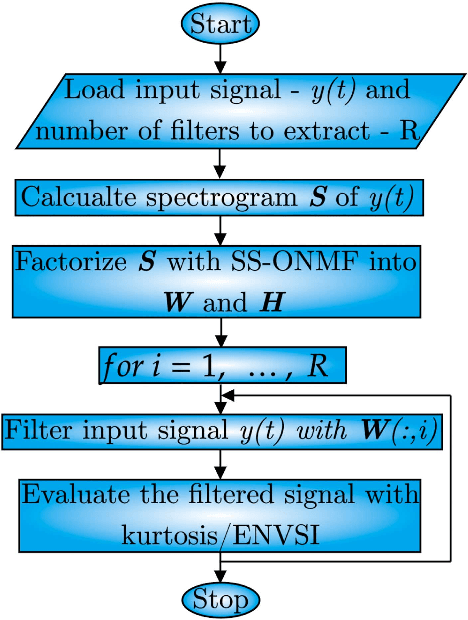

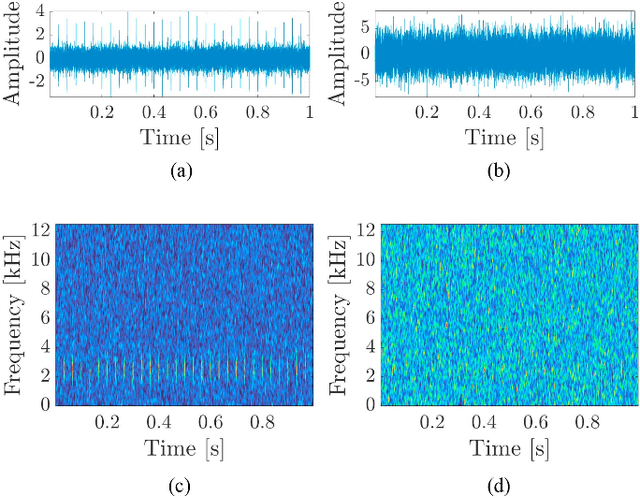

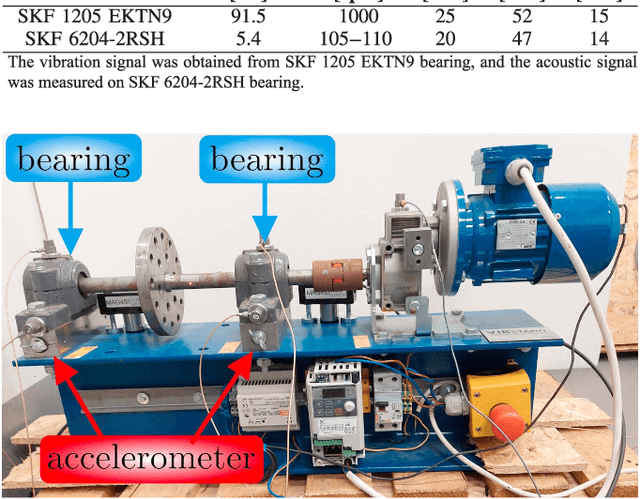

Abstract:Local damage of bearings can be detected as a weak cyclic and impulsive component in a highly noisy measured signal. A key problem is how to extract the signal of interest (SOI) from the raw signal, i.e., how to identify and design an optimal filter. To tackle this problem, we propose to use stochastic sampled orthogonal non-negative matrix factorization for extracting frequency-based features from a spectrogram of the measured signal. The proposed algorithm finds a selective filter that is tailored to the frequency band of the SOI. We show that our approach outperforms the other state-of-the-art selectors that were previously used in condition monitoring. The efficiency of the proposed method is illustrated using both a simulation study and the following real signals: (a) vibration signal from a test rig in the laboratory and (b) acoustic signal from a belt conveyor.

Non-negative matrix underapproximation as optimal frequency band selector

Mar 19, 2024

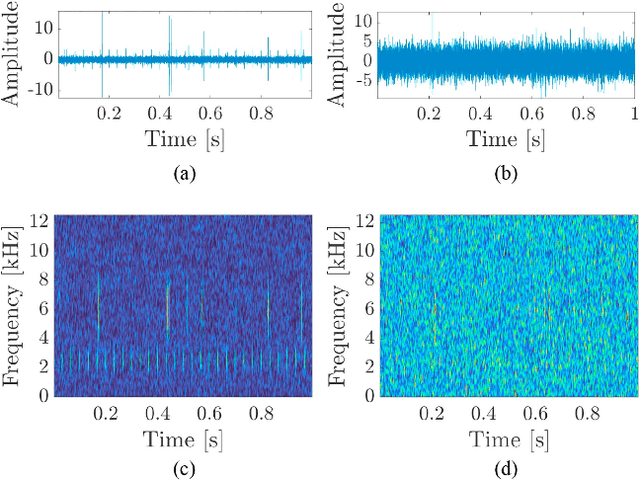

Abstract:Time-frequency representation (TFR) is often used for non-stationary signal analysis. The most intuitive and interpretable TFR is the spectrogram. Recently, a concept of non-negative matrix factorization (NMF) has been successfully applied to local damage detection in rolling elements of bearings via spectrogram factorization. NMF applied to the spectrogram allows one to find an informative frequency band, which could be further used as a filter characteristic. However, the obtained filter characteristics mostly detect the informative frequency band, which also encompasses a lot of noise. In the case where noise is more problematic, as is the case for acoustic signals from industrial machines, the NMF hardly detects the damage. To solve this problem and obtain more selective filters, which are more robust to noise, we propose the non-negative matrix under-approximation (NMU) as an informative frequency band selector. Due to the more sparse parts-based representation of the NMU compared to NMF, NMU provides more selective filter characteristics, which neglect the non-informative frequency bands related to the noise. In practice, it means that NMU gives a better signal-to-noise ratio for the filtered signal. The efficiency of the proposed approach has been validated on the vibration signal from the test rig and the acoustic signal from an idler.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge