Quinn Zhang

A Physics-Guided Neural Operator Learning Approach to Model Biological Tissues from Digital Image Correlation Measurements

Apr 01, 2022

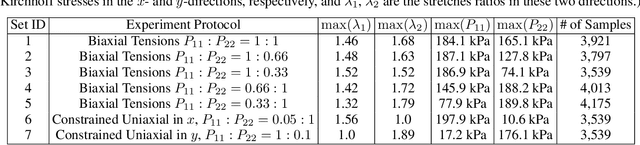

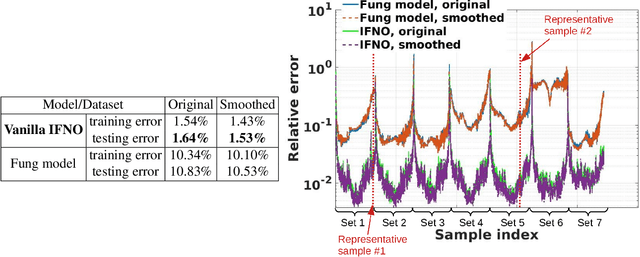

Abstract:We present a data-driven workflow to biological tissue modeling, which aims to predict the displacement field based on digital image correlation (DIC) measurements under unseen loading scenarios, without postulating a specific constitutive model form nor possessing knowledges on the material microstructure. To this end, a material database is constructed from the DIC displacement tracking measurements of multiple biaxial stretching protocols on a porcine tricuspid valve anterior leaflet, with which we build a neural operator learning model. The material response is modeled as a solution operator from the loading to the resultant displacement field, with the material microstructure properties learned implicitly from the data and naturally embedded in the network parameters. Using various combinations of loading protocols, we compare the predictivity of this framework with finite element analysis based on the phenomenological Fung-type model. From in-distribution tests, the predictivity of our approach presents good generalizability to different loading conditions and outperforms the conventional constitutive modeling at approximately one order of magnitude. When tested on out-of-distribution loading ratios, the neural operator learning approach becomes less effective. To improve the generalizability of our framework, we propose a physics-guided neural operator learning model via imposing partial physics knowledge. This method is shown to improve the model's extrapolative performance in the small-deformation regime. Our results demonstrate that with sufficient data coverage and/or guidance from partial physics constraints, the data-driven approach can be a more effective method for modeling biological materials than the traditional constitutive modeling.

Learning Deep Implicit Fourier Neural Operators (IFNOs) with Applications to Heterogeneous Material Modeling

Mar 15, 2022

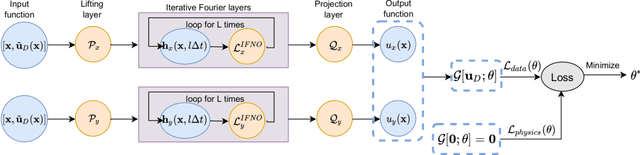

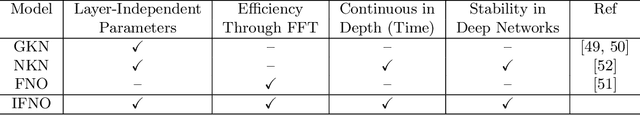

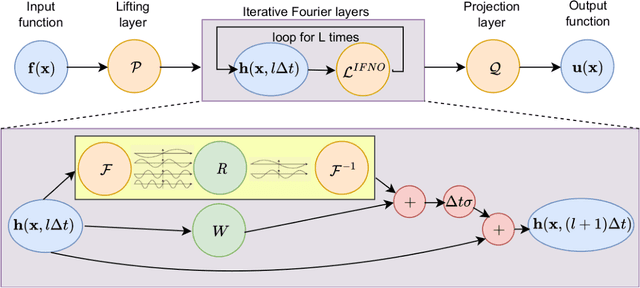

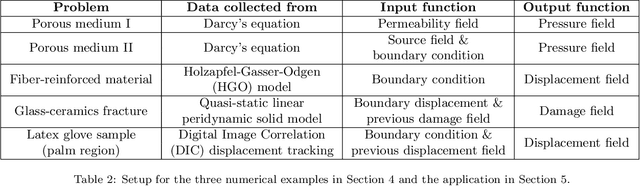

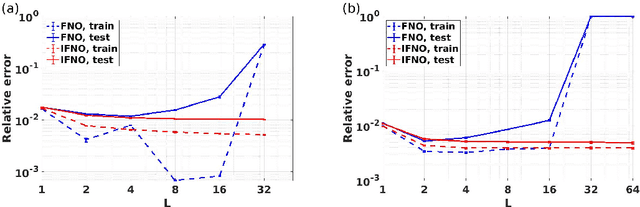

Abstract:Constitutive modeling based on continuum mechanics theory has been a classical approach for modeling the mechanical responses of materials. However, when constitutive laws are unknown or when defects and/or high degrees of heterogeneity are present, these classical models may become inaccurate. In this work, we propose to use data-driven modeling, which directly utilizes high-fidelity simulation and/or experimental measurements to predict a material's response without using conventional constitutive models. Specifically, the material response is modeled by learning the implicit mappings between loading conditions and the resultant displacement and/or damage fields, with the neural network serving as a surrogate for a solution operator. To model the complex responses due to material heterogeneity and defects, we develop a novel deep neural operator architecture, which we coin as the Implicit Fourier Neural Operator (IFNO). In the IFNO, the increment between layers is modeled as an integral operator to capture the long-range dependencies in the feature space. As the network gets deeper, the limit of IFNO becomes a fixed point equation that yields an implicit neural operator and naturally mimics the displacement/damage fields solving procedure in material modeling problems. We demonstrate the performance of our proposed method for a number of examples, including hyperelastic, anisotropic and brittle materials. As an application, we further employ the proposed approach to learn the material models directly from digital image correlation (DIC) tracking measurements, and show that the learned solution operators substantially outperform the conventional constitutive models in predicting displacement fields.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge