Nicole Duarte

Intuitive Robot Programming by Capturing Human Manufacturing Skills: A Framework for the Process of Glass Adhesive Application

Sep 15, 2022

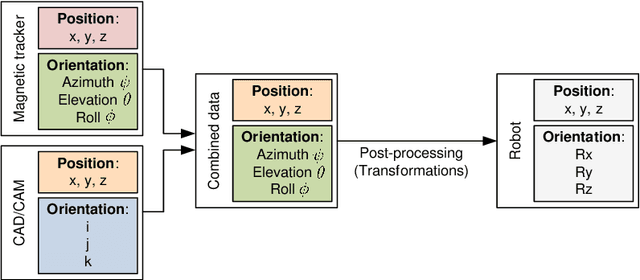

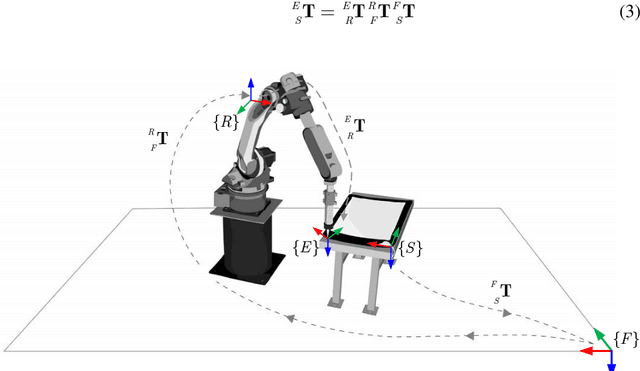

Abstract:There is a great demand for the robotization of manufacturing processes fea-turing monotonous labor. Some manufacturing tasks requiring specific skills (welding, painting, etc.) suffer from a lack of workers. Robots have been used in these tasks, but their flexibility is limited since they are still difficult to program/re-program by non-experts, making them inaccessible to most companies. Robot offline programming (OLP) is reliable. However, generat-ed paths directly from CAD/CAM do not include relevant parameters repre-senting human skills such as robot end-effector orientations and velocities. This paper presents an intuitive robot programming system to capture human manufacturing skills and transform them into robot programs. Demonstra-tions from human skilled workers are recorded using a magnetic tracking system attached to the worker tools. Collected data include the orientations and velocity of the working paths. Positional data are extracted from CAD/CAM since its error when captured by the magnetic tracker, is signifi-cant. Paths poses are transformed in Cartesian space and validated in a simu-lation environment. Robot programs are generated and transferred to the real robot. Experiments on the process of glass adhesive application demonstrat-ed the intuitiveness to use and effectiveness of the proposed framework in capturing human skills and transferring them to the robot.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge