Mathias Ziegler

Nondestructive thermographic detection of internal defects using pixel-pattern based laser excitation and photothermal super resolution reconstruction

Nov 08, 2022Abstract:Thermographic testing, as a non-destructive testing method, is a non-contact imaging technique for examining specimens by characterizing their thermal conduction behavior. One of the main limitations of thermography is the inherent limit to the resolution of the internal structures of any specimen due to the diffusive nature of heat conduction. Overcoming this limit is the goal of thermographic super resolution methods. In this work, we present a method using two-dimensional pixel pattern based active photothermal laser heating in conjunction with subsequent numerical reconstruction to achieve a high-resolution reconstruction of internal defect structures. Furthermore, a forward solution to the underlying inverse problem is proposed along with an appropriate heuristic to find the regularization parameters necessary for the inversion in a laboratory setting. This allows the generation of synthetic measurement data, opening the door for the application of machine learning based methods for future improvements towards full automation of the method. The proposed experimental approach is validated using the latest laser coupled DLP projector technology as a heat source. Finally, the proposed method is shown to outperform several established conventional thermographic testing techniques while improving the required measurement times by a factor of 8 compared to currently available photothermal super resolution techniques.

Thermographic detection of internal defects using 2D photothermal super resolution reconstruction with sequential laser heating

Mar 25, 2022

Abstract:Thermographic photothermal super resolution reconstruction enables the resolution of internal defects/inhomogeneities below the classical limit which is governed by the diffusion properties of thermal wave propagation. Based on a combination of the application of special sampling strategies and a subsequent numerical optimization step in post-processing, thermographic super resolution has already proven to be superior to standard thermographic methods in the detection of one-dimensional defect/inhomogeneity structures. In our work, we report an extension of the capabilities of the method for efficient detection and resolution of defect cross sections with fully two-dimensional structured laser-based heating. The reconstruction is carried out using one of two different algorithms which are proposed within this work. Both algorithms utilize the combination of several coherent measurements using convex optimization and exploit the sparse nature of defects/inhomogeneities as is typical for most nondestructive testing scenarios. Finally, the performance of each algorithm is rated on reconstruction quality and algorithmic complexity. The presented experimental approach is based on repeated spatially structured heating by a high power laser. As a result, a two-dimensional sparse defect/inhomogeneity map can be obtained. In addition, the obtained results are compared with those of conventional thermographic inspection methods which make use of homogeneous illumination.

Photothermal-SR-Net: A Customized Deep Unfolding Neural Network for Photothermal Super Resolution Imaging

Apr 21, 2021

Abstract:This paper presents deep unfolding neural networks to handle inverse problems in photothermal radiometry enabling super resolution (SR) imaging. Photothermal imaging is a well-known technique in active thermography for nondestructive inspection of defects in materials such as metals or composites. A grand challenge of active thermography is to overcome the spatial resolution limitation imposed by heat diffusion in order to accurately resolve each defect. The photothermal SR approach enables to extract high-frequency spatial components based on the deconvolution with the thermal point spread function. However, stable deconvolution can only be achieved by using the sparse structure of defect patterns, which often requires tedious, hand-crafted tuning of hyperparameters and results in computationally intensive algorithms. On this account, Photothermal-SR-Net is proposed in this paper, which performs deconvolution by deep unfolding considering the underlying physics. This enables to super resolve 2D thermal images for nondestructive testing with a substantially improved convergence rate. Since defects appear sparsely in materials, Photothermal-SR-Net applies trained block-sparsity thresholding to the acquired thermal images in each convolutional layer. The performance of the proposed approach is evaluated and discussed using various deep unfolding and thresholding approaches applied to 2D thermal images. Subsequently, studies are conducted on how to increase the reconstruction quality and the computational performance of Photothermal-SR-Net is evaluated. Thereby, it was found that the computing time for creating high-resolution images could be significantly reduced without decreasing the reconstruction quality by using pixel binning as a preprocessing step.

Learned Block Iterative Shrinkage Thresholding Algorithm for Photothermal Super Resolution Imaging

Dec 10, 2020

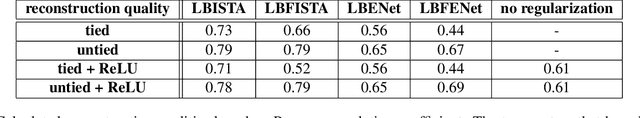

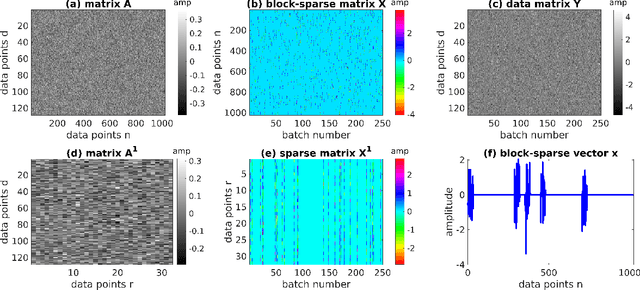

Abstract:Block-sparse regularization is already well-known in active thermal imaging and is used for multiple measurement based inverse problems. The main bottleneck of this method is the choice of regularization parameters which differs for each experiment. To avoid time-consuming manually selected regularization parameter, we propose a learned block-sparse optimization approach using an iterative algorithm unfolded into a deep neural network. More precisely, we show the benefits of using a learned block iterative shrinkage thresholding algorithm that is able to learn the choice of regularization parameters. In addition, this algorithm enables the determination of a suitable weight matrix to solve the underlying inverse problem. Therefore, in this paper we present the algorithm and compare it with state of the art block iterative shrinkage thresholding using synthetically generated test data and experimental test data from active thermography for defect reconstruction. Our results show that the use of the learned block-sparse optimization approach provides smaller normalized mean square errors for a small fixed number of iterations than without learning. Thus, this new approach allows to improve the convergence speed and only needs a few iterations to generate accurate defect reconstruction in photothermal super resolution imaging.

Classification of Spot-welded Joints in Laser Thermography Data using Convolutional Neural Networks

Oct 24, 2020

Abstract:Spot welding is a crucial process step in various industries. However, classification of spot welding quality is still a tedious process due to the complexity and sensitivity of the test material, which drain conventional approaches to its limits. In this paper, we propose an approach for quality inspection of spot weldings using images from laser thermography data.We propose data preparation approaches based on the underlying physics of spot welded joints, heated with pulsed laser thermography by analyzing the intensity over time and derive dedicated data filters to generate training datasets. Subsequently, we utilize convolutional neural networks to classify weld quality and compare the performance of different models against each other. We achieve competitive results in terms of classifying the different welding quality classes compared to traditional approaches, reaching an accuracy of more than 95 percent. Finally, we explore the effect of different augmentation methods.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge