Marco Pontin

Compliant Beaded-String Jamming For Variable Stiffness Anthropomorphic Fingers

Feb 06, 2025

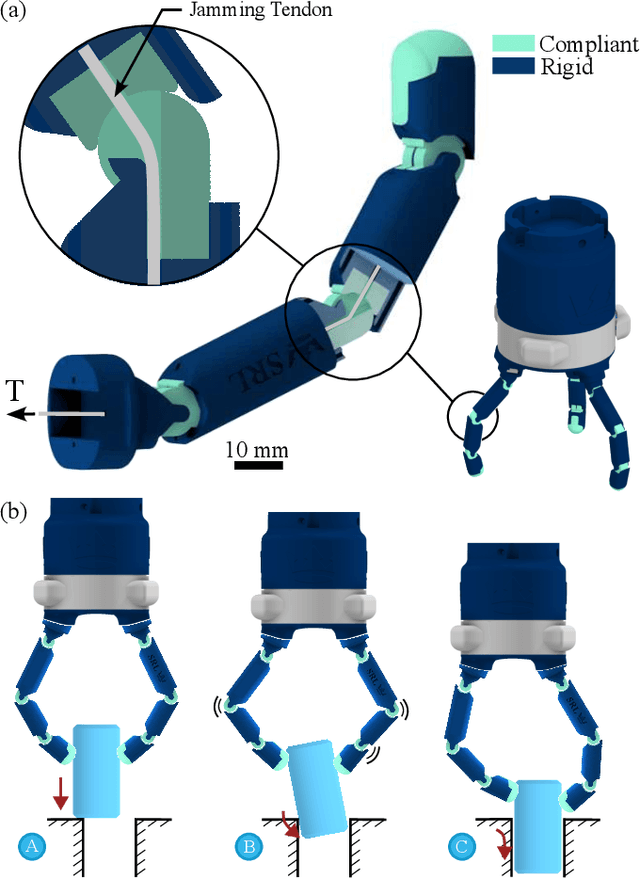

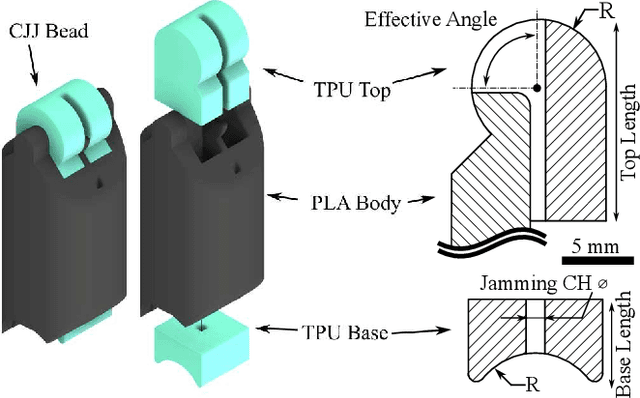

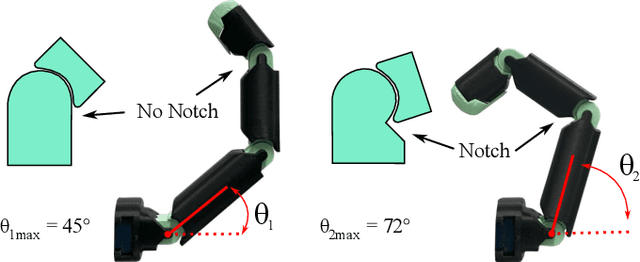

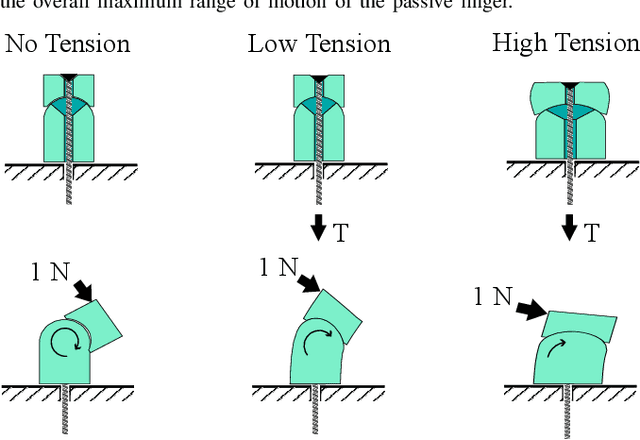

Abstract:Achieving human-like dexterity in robotic grippers remains an open challenge, particularly in ensuring robust manipulation in uncertain environments. Soft robotic hands try to address this by leveraging passive compliance, a characteristic that is crucial to the adaptability of the human hand, to achieve more robust manipulation while reducing reliance on high-resolution sensing and complex control. Further improvements in terms of precision and postural stability in manipulation tasks are achieved through the integration of variable stiffness mechanisms, but these tend to lack residual compliance, be bulky and have slow response times. To address these limitations, this work introduces a Compliant Joint Jamming mechanism for anthropomorphic fingers that exhibits passive residual compliance and adjustable stiffness, while achieving a range of motion in line with that of human interphalangeal joints. The stiffness range provided by the mechanism is controllable from 0.48 Nm/rad to 1.95 Nm/rad (a 4x increase). Repeatability, hysteresis and stiffness were also characterized as a function of the jamming force. To demonstrate the importance of the passive residual compliance afforded by the proposed system, a peg-in-hole task was conducted, which showed a 60% higher success rate for a gripper integrating our joint design when compared to a rigid one.

Soft and Highly-Integrated Optical Fiber Bending Sensors for Proprioception in Multi-Material 3D Printed Fingers

Feb 06, 2025Abstract:Accurate shape sensing, only achievable through distributed proprioception, is a key requirement for closed-loop control of soft robots. Low-cost power efficient optoelectronic sensors manufactured from flexible materials represent a natural choice as they can cope with the large deformations of soft robots without loss of performance. However, existing integration approaches are cumbersome and require manual steps and complex assembly. We propose a semi-automated printing process where plastic optical fibers are embedded with readout electronics in 3D printed flexures. The fibers become locked in place and the readout electronics remain optically coupled to them while the flexures undergo large bending deformations, creating a repeatable, monolithically manufactured bending transducer with only 10 minutes required in total for the manual embedding steps. We demonstrate the process by manufacturing multi-material 3D printed fingers and extensively evaluating the performance of each proprioceptive joint. The sensors achieve 70% linearity and 4.81{\deg} RMS error on average. Furthermore, the distributed architecture allows for maintaining an average fingertip position estimation accuracy of 12 mm in the presence of external static forces. To demonstrate the potential of the distributed sensor architecture in robotics applications, we build a data-driven model independent of actuation feedback to detect contact with objects in the environment.

JAMMit! Monolithic 3D-Printing of a Bead Jamming Soft Pneumatic Arm

Feb 05, 2025Abstract:3D-printed bellow soft pneumatic arms are widely adopted for their flexible design, ease of fabrication, and large deformation capabilities. However, their low stiffness limits their real-world applications. Although several methods exist to enhance the stiffness of soft actuators, many involve complex manufacturing processes not in line with modern goals of monolithic and automated additive manufacturing. With its simplicity, bead-jamming represents a simple and effective solution to these challenges. This work introduces a method for monolithic printing of a bellow soft pneumatic arm, integrating a tendon-driven central spine of bowl-shaped beads. We experimentally characterized the arm's range of motion in both unjammed and jammed states, as well as its stiffness under various actuation and jamming conditions. As a result, we provide an optimal jamming policy as a trade-off between preserving the range of motion and maximizing stiffness. The proposed design was further demonstrated in a switch-toggling task, showing its potential for practical applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge